Tank container frame assembly platform system

A technology for tank containers and platforms, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large errors and difficult to achieve safety, and achieve the goal of ensuring accuracy, reducing labor intensity, and improving safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

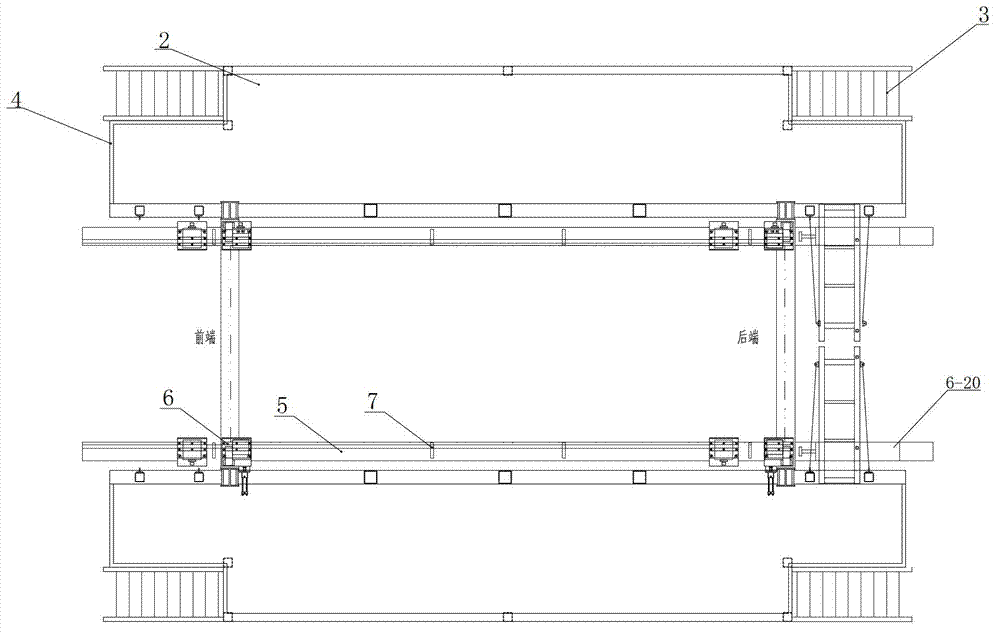

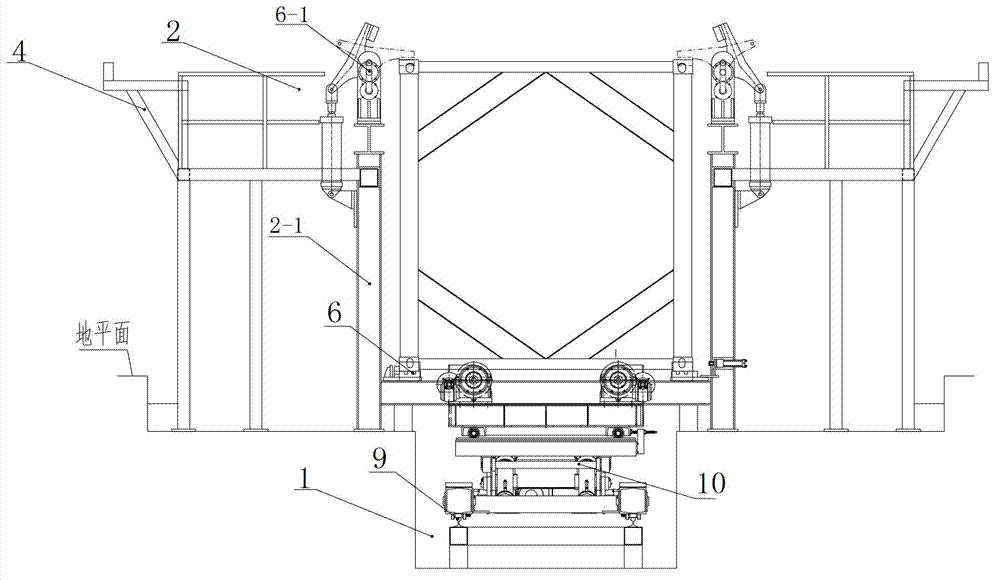

[0021] see Figure 1 to Figure 8 , a tank-type container frame assembly platform system, the system mainly includes a foundation pit 1, an operating platform 2 parallel to each other located on both sides of the foundation pit, a ladder 3 is provided between the operating platform 2 and the ground, and a ladder 3 is arranged on the operating platform. There are guardrails 4, the operating platform is fixedly installed on the base beam 5, and the base beam 5 is fixedly installed on the foundation; the front and rear ends of the operating platform 2 are respectively installed on the base beams 5 with the front and rear frames of the tank container fixed Device 6, the base beam 5 is movably installed with a fixed support frame 7 for fixing the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com