Support structure for boss

A technology of supporting structures and bosses, applied in the installation of cables, busbars, bases/shells, etc., can solve problems such as cracks, electrical connection failures, failures, etc., to improve dimensional accuracy, prevent short shots, and prevent cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

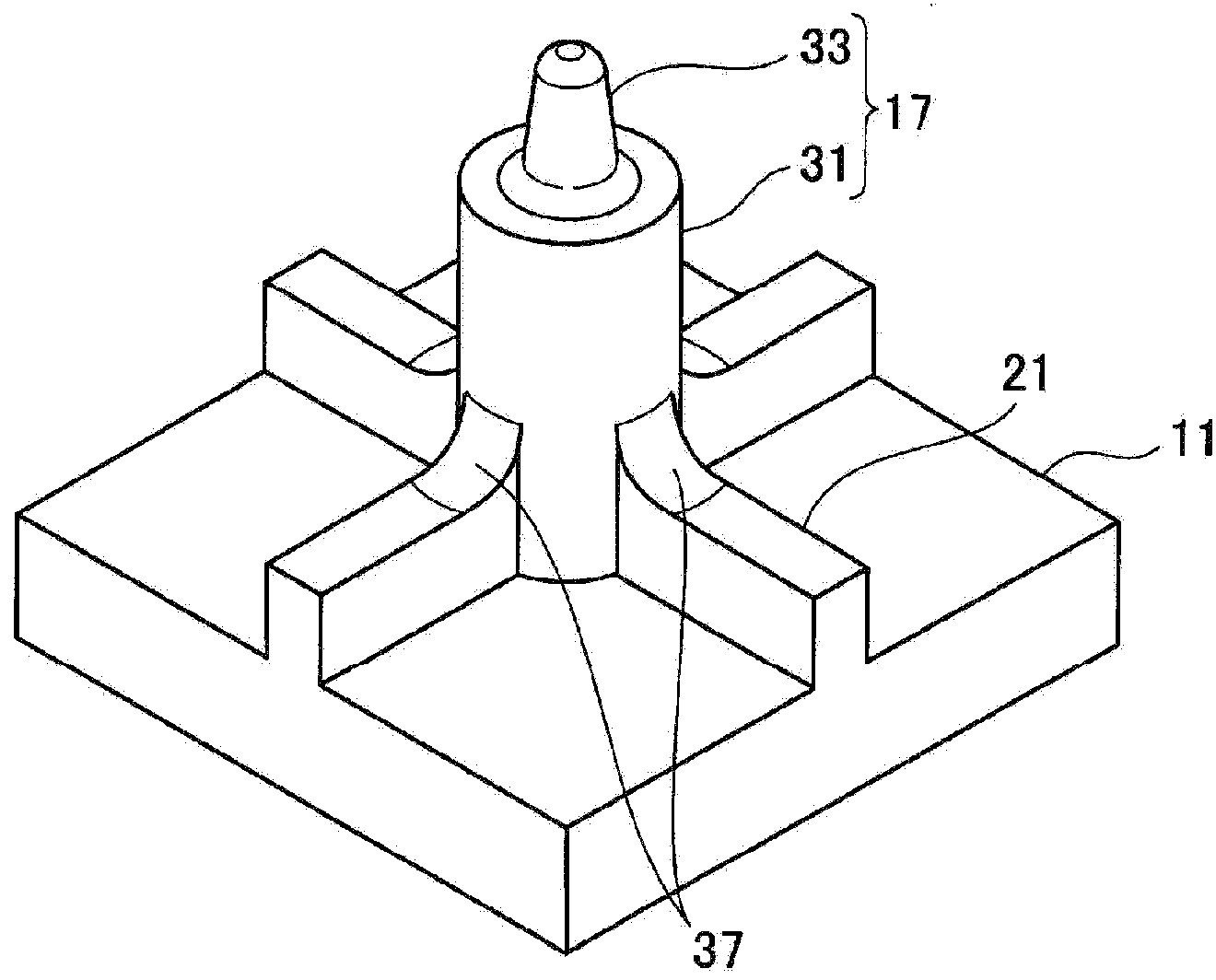

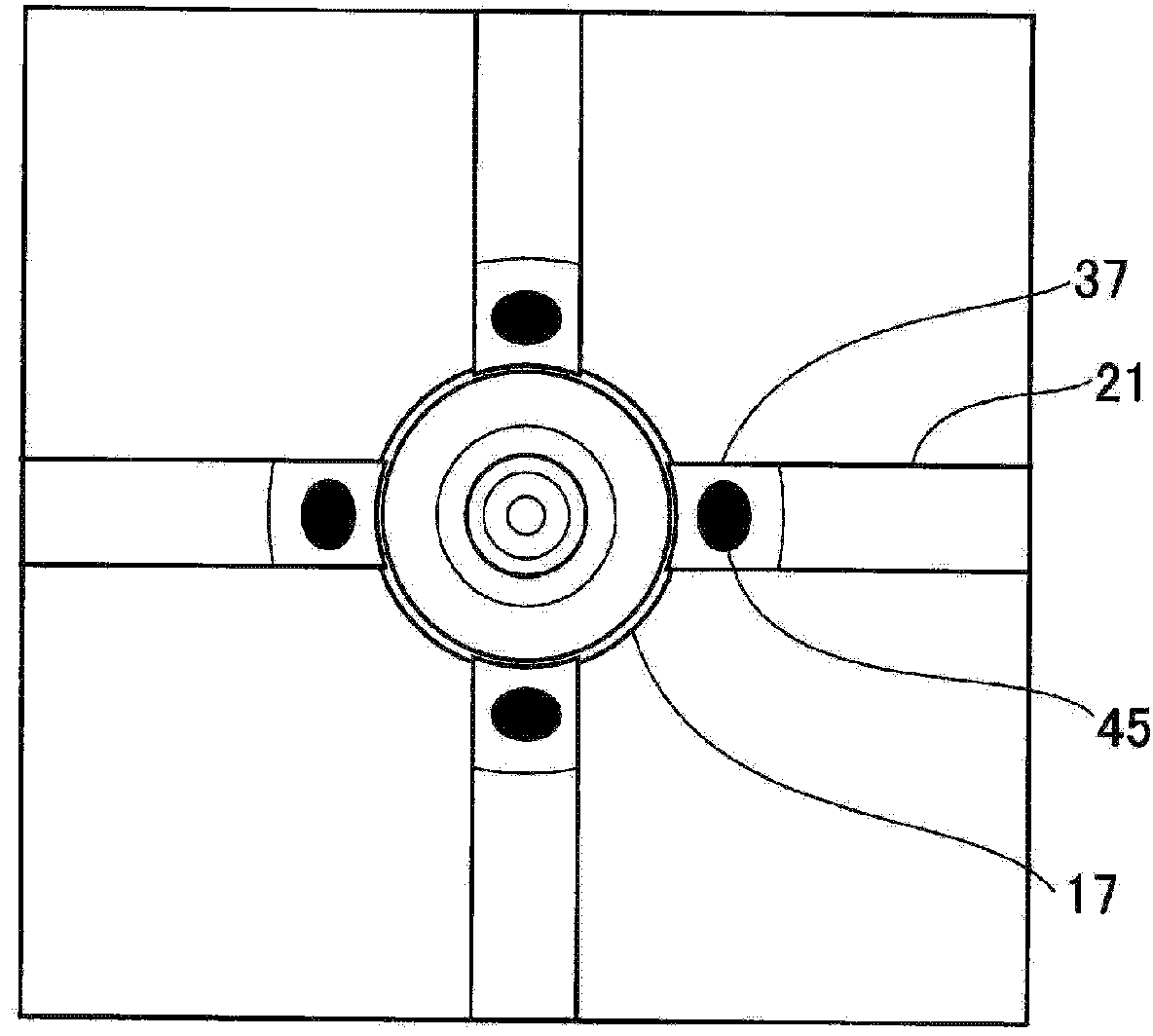

[0026] Hereinafter, a support structure for a boss of a resin molded product according to an embodiment of the present invention will now be described with reference to the accompanying drawings. In this example, the description will be formed in Figure 8 with Figure 9 The support structure for the boss 17 in the electrical junction box shown in . Also, in the following descriptions, configurations other than the support structure for bosses are made with Figure 8 with Figure 9 are denoted by the same reference numerals as those in , and a detailed description thereof will be omitted.

[0027] First, in order to easily understand the support structure for the boss 17 according to the present invention, the support structure for the boss 17 according to the prior art will be described.

[0028] The base plate 11 forming the bottom surface of the frame body 13 is provided with a plurality of bosses 17 ( Figure 8 ). The boss 17 includes a body portion 31 formed in a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com