Wire clamping device with horn mouth

A technology of wire gripper and bell mouth, which is applied in the field of equipment, can solve the problems of low wire clamping force, influence of wiring speed, easy loosening, etc., and achieve the effect of stable contact, prolonging service life and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

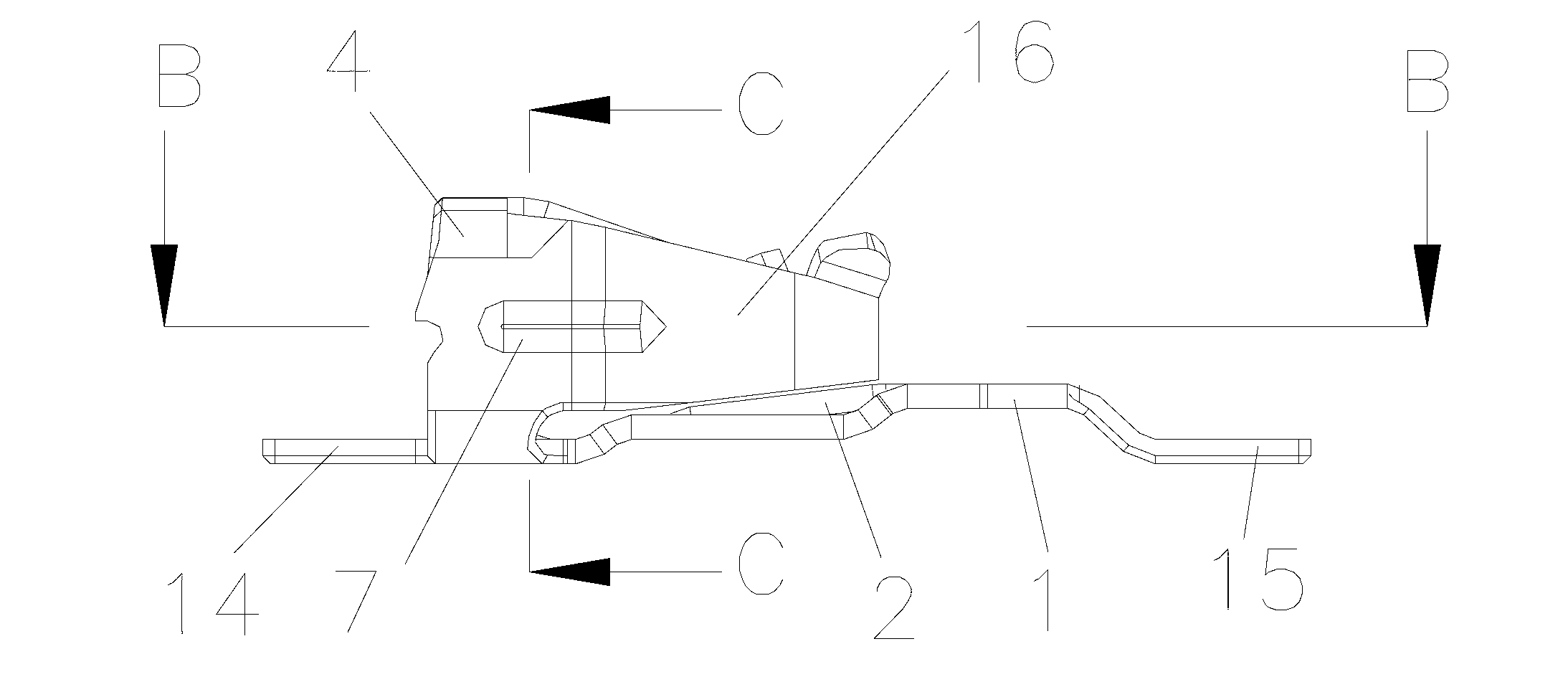

[0024] like Figure 1-12 As shown, a wire gripper with a bell mouth according to the embodiment of the present invention includes a fixed base 1 with an arched middle part, and is characterized in that: an elastic piece 2 is provided in the middle of the fixed base 1; 1 Both ends are respectively provided with a left welding piece 14 and a right welding piece 15, the left welding piece 14 is provided with a welding through hole 9, and the right welding piece 15 is provided with a welding groove 3; the left end of the fixed base 1 A conduction ring 4 is provided, and the two sides of the conduction ring 4 and the top of the conduction ring 4 are respectively provided with a left blade 5, a right blade 16 and a top blade 6, and the left blade 5, the right blade 16 and the top blade The blades 6 are bell-shaped, and the connecting parts of the left blade 5 and the right blade 16 and the conduction ring 4 are provided with reinforcing ribs 7 . The left blade 5, the right blade 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com