Capacitor of lithium ion battery

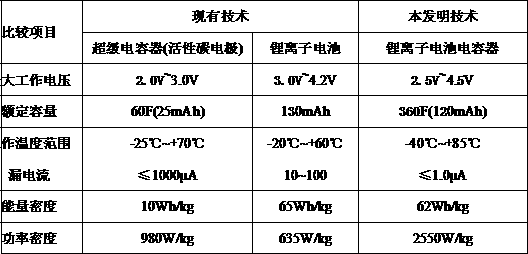

A technology for lithium-ion batteries and capacitors, applied in electrolytic capacitors, capacitors, double-layer capacitors, etc., can solve the problems of large surface area, reduce energy density, consume large lithium ions, etc., achieve low self-discharge rate, enhance practicability, widen Effects of Using Temperature Range and Voltage Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

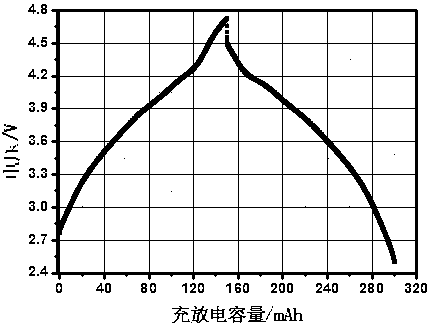

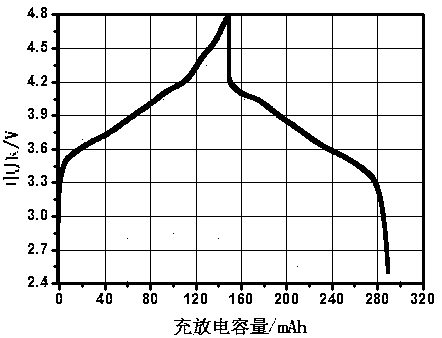

Embodiment 1

[0022] 1520 type (diameter 15.0mm, height 20.0mm) cylindrical lithium ion battery capacitor, the negative plate of the capacitor is composed of 50% hard carbon and 50% natural graphite (capacity percentage) as active material, and then combined with carboxymethyl fiber Soluble styrene-butadiene rubber binder, and superconducting acetylene black are mixed evenly, and deionized water is used as a solvent, stirred into a slurry, and coated on a 15-micron copper foil; the positive plate is made of 95% LiMn 2 o 4 and 5% activated carbon (volume percentage) to form the active material, and then mix it evenly with conductive graphite, superconducting acetylene black and polyvinylidene fluoride binder, use N-methylpyrrolidone as a solvent, stir into a slurry, and coat It is made on 20 micron aluminum foil; the positive and negative electrodes are separated by polypropylene-polyethylene-polypropylene microporous membrane and wound to form a core. The negative ear is drawn to the posit...

Embodiment 2

[0024] 1520 type (diameter 15.0mm, height 20.0mm) cylindrical lithium ion battery capacitor, the negative plate of the capacitor is composed of 95% soft carbon and 5% modified graphite (capacity percentage) as active material, and then combined with carboxymethyl group Cellulose, soluble styrene-butadiene rubber binder, and superconducting acetylene black are mixed evenly, and deionized water is used as a solvent, stirred into a slurry, and coated on a 15-micron copper foil; the positive plate is made of 80% LiCoO 2 and LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The active material is composed of 20% activated carbon (volume percentage), and then mixed evenly with conductive graphite, superconducting acetylene black and polyvinylidene fluoride binder, using N-methylpyrrolidone as a solvent, stirred into a slurry, and coated It is made on 20 micron aluminum foil; the positive and negative electrodes are separated by polypropylene-polyethylene-polypropylene microporous membrane and wound to ...

Embodiment 3

[0026] 1520 (diameter 15.0mm, height 20.0mm) type cylindrical lithium ion battery capacitor, the negative plate of the capacitor is composed of 75% hard carbon and soft carbon mixed with 25% artificial graphite and natural graphite (capacity percentage) to form the active material , and then mixed with carboxymethyl cellulose, soluble styrene-butadiene rubber binder, and superconducting acetylene black, using deionized water as a solvent, stirred into a slurry, and coated on a 15-micron copper foil; The positive plate is made of 50% LiNi 0.8 co 0.2 o 2 And 50% activated carbon (volume percentage) to form the active material, then mix with conductive graphite, superconducting acetylene black and polyvinylidene fluoride binder, use N-methylpyrrolidone as solvent, stir into slurry, and coat It is made on 20 micron aluminum foil; the positive and negative electrodes are separated by polypropylene-polyethylene-polypropylene microporous membrane and wound to form a core. The nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com