Automatic wire and cable take-up and winding displacement device

A wire and cable, winding and arranging technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of large mechanical wear of gear commutation, complex mechanical coupling connection structure, etc., to achieve wide adaptability, good practicality Value, the effect of simple wiring operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

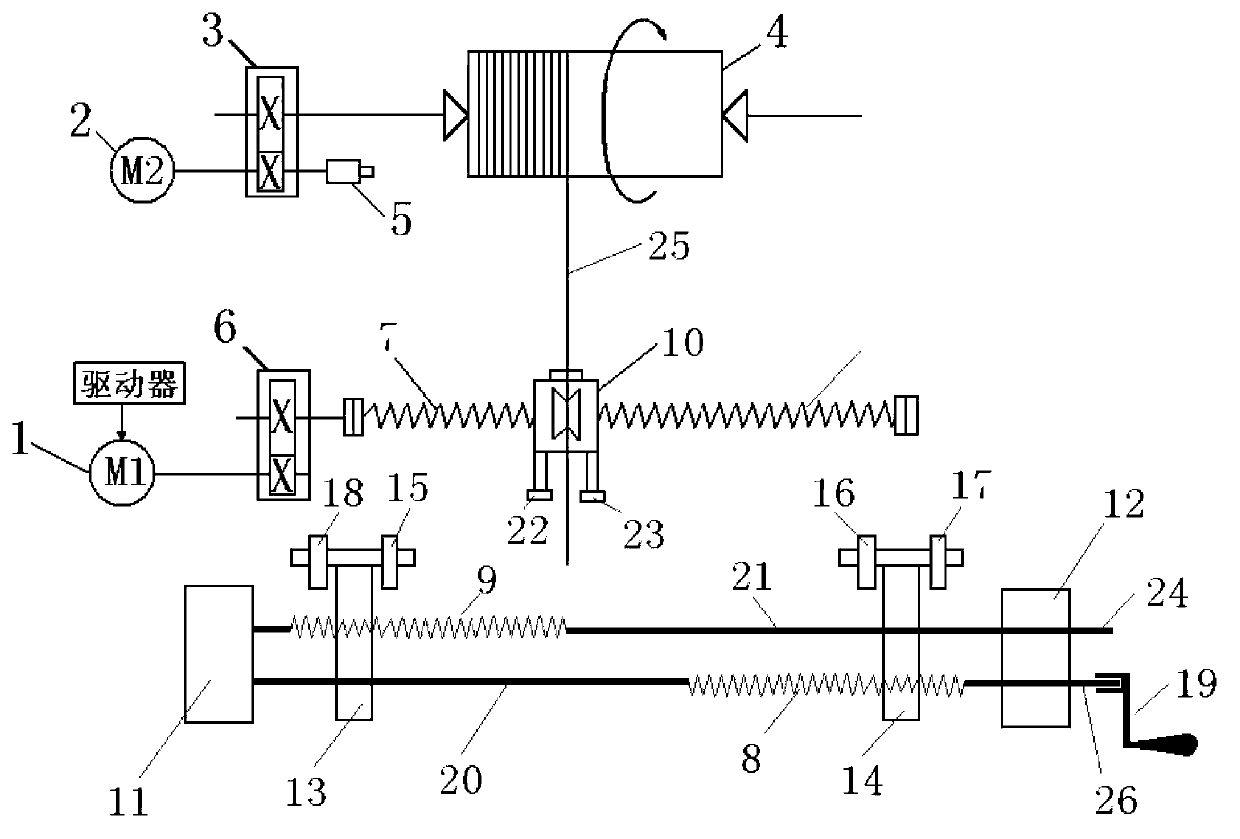

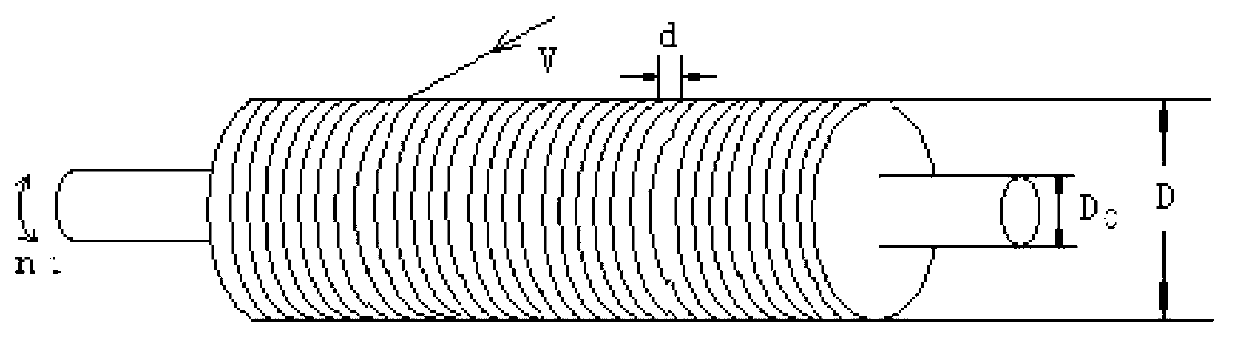

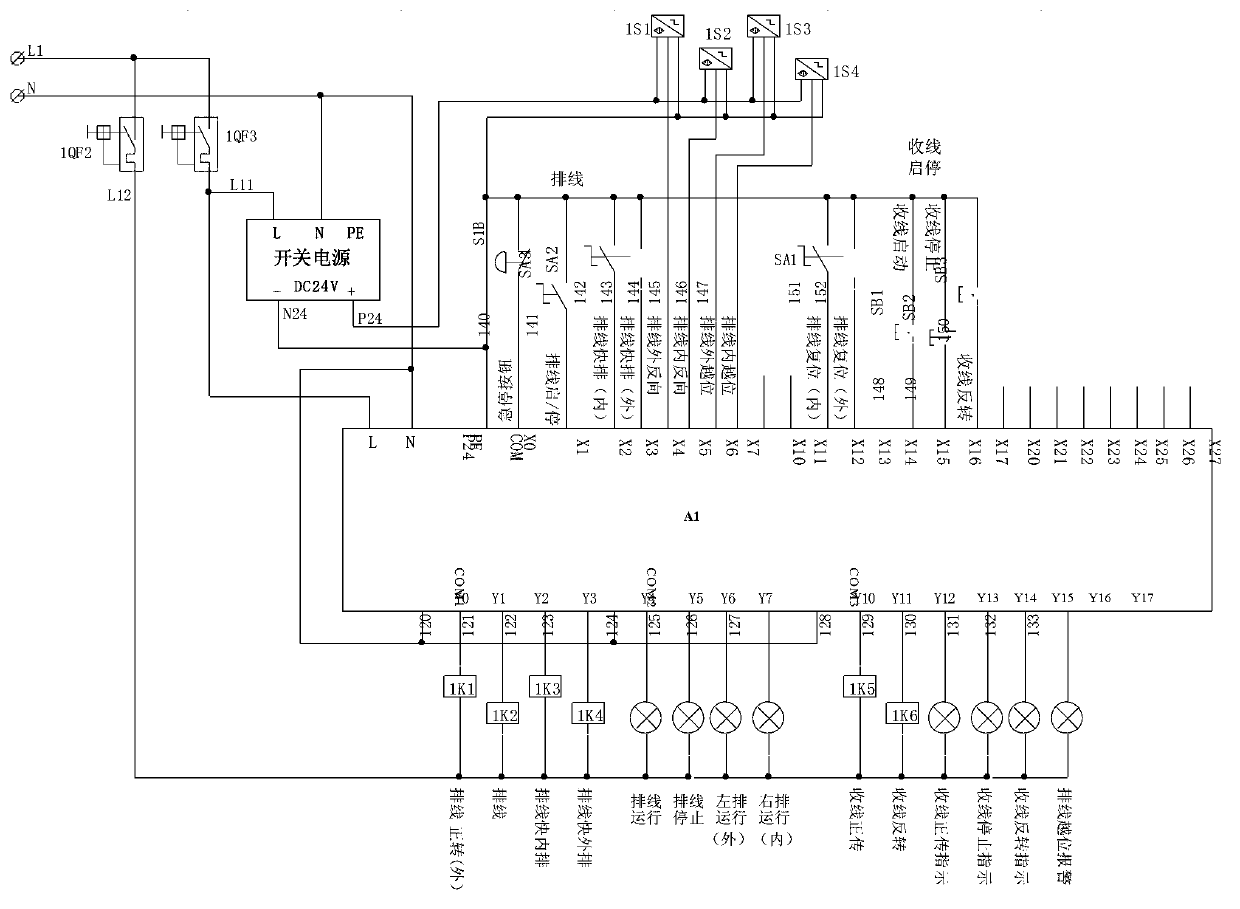

[0018] as follows figure 1 As shown, it is a structural diagram of the automatic wire and cable winding device of the present invention. As can be seen from the figure, the device includes a winding motor 2 and a winding reel 4 driven and controlled by the winding reel. The drum, the winding shaft is connected with the winding motor 2 for transmission control, and also includes an automatic wire winding mechanism composed of a wire winding mechanism and an automatic reversing mechanism. The wire winding mechanism includes a wire winding screw 7 driven by the wire winding motor 1 The cable guide 10 installed on the cable guide screw and forming the structure of the screw screw machine with it; Two reversing proximity switches 15 and 16 on the left and right, the two reversing proximity switches are controlled by a controller, and are installed on the corresponding left and right mobile frames 13 and 14 respectively, and the two mobile frames can move along the horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com