Method for monitoring health status of metallurgical equipment

A technology of health status and metallurgical equipment, applied in electrical testing/monitoring, special data processing applications, instruments, etc., can solve problems such as insufficient flexibility in scheduling modification, insufficient analysis functions of point inspection results, and inability to realize transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

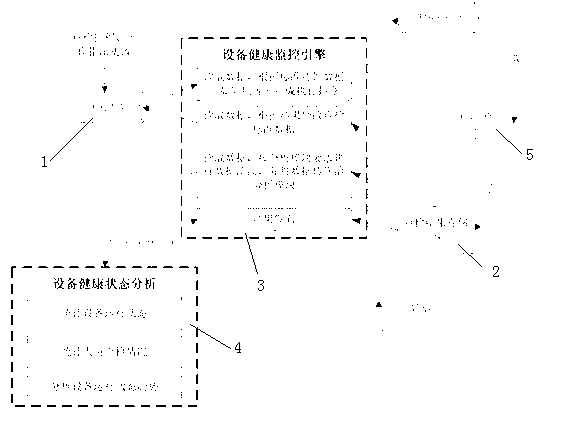

[0013] Such as figure 1 Shown:, a kind of metallurgical equipment health status monitoring method, it comprises wireless spot checking instrument 5, and described wireless spot checking instrument is RFID wireless spot checking instrument, and it also includes:

[0014] Inspection standard library 1, which contains various information required for inspection operations, equipment information, cycle information, operator information, route information and start-up identification;

[0015] Inspection result memory 2; contains inspection operation results, completion status identification, and is associated with each information in the inspection standard table through a unique identification;

[0016] Equipment health monitoring engine 3, which has three functions of point inspection execution instruction preparation, automatic scheduling of point inspection standards and result release, respectively generates command plans to be executed and automatic scheduling of spot inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com