Three-point high-precision large-aperture electric reflector frame

A mirror frame, three-point technology, used in installation, optics, instruments, etc., to achieve the effects of convenient debugging and maintenance operations, simple structure, high reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

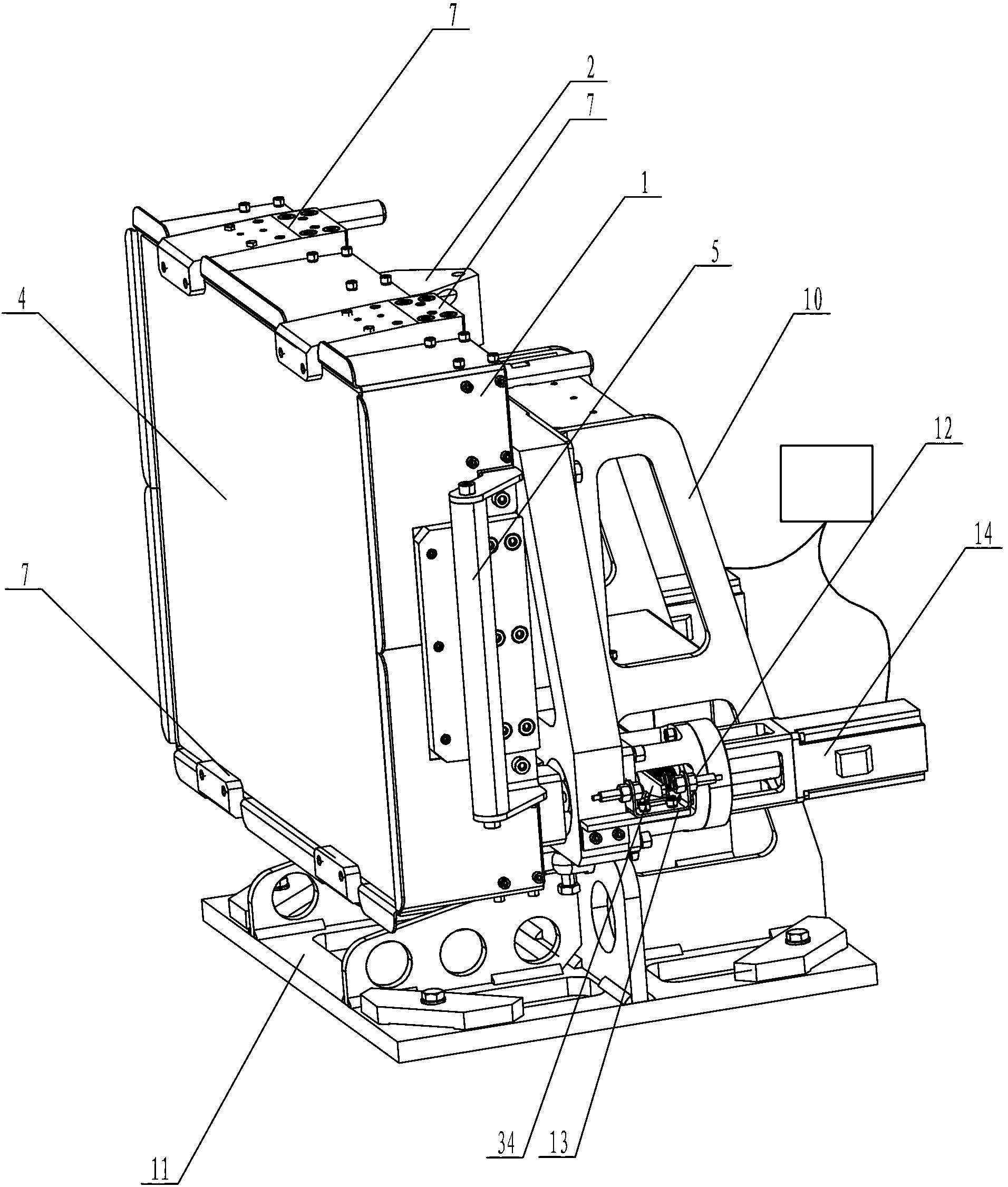

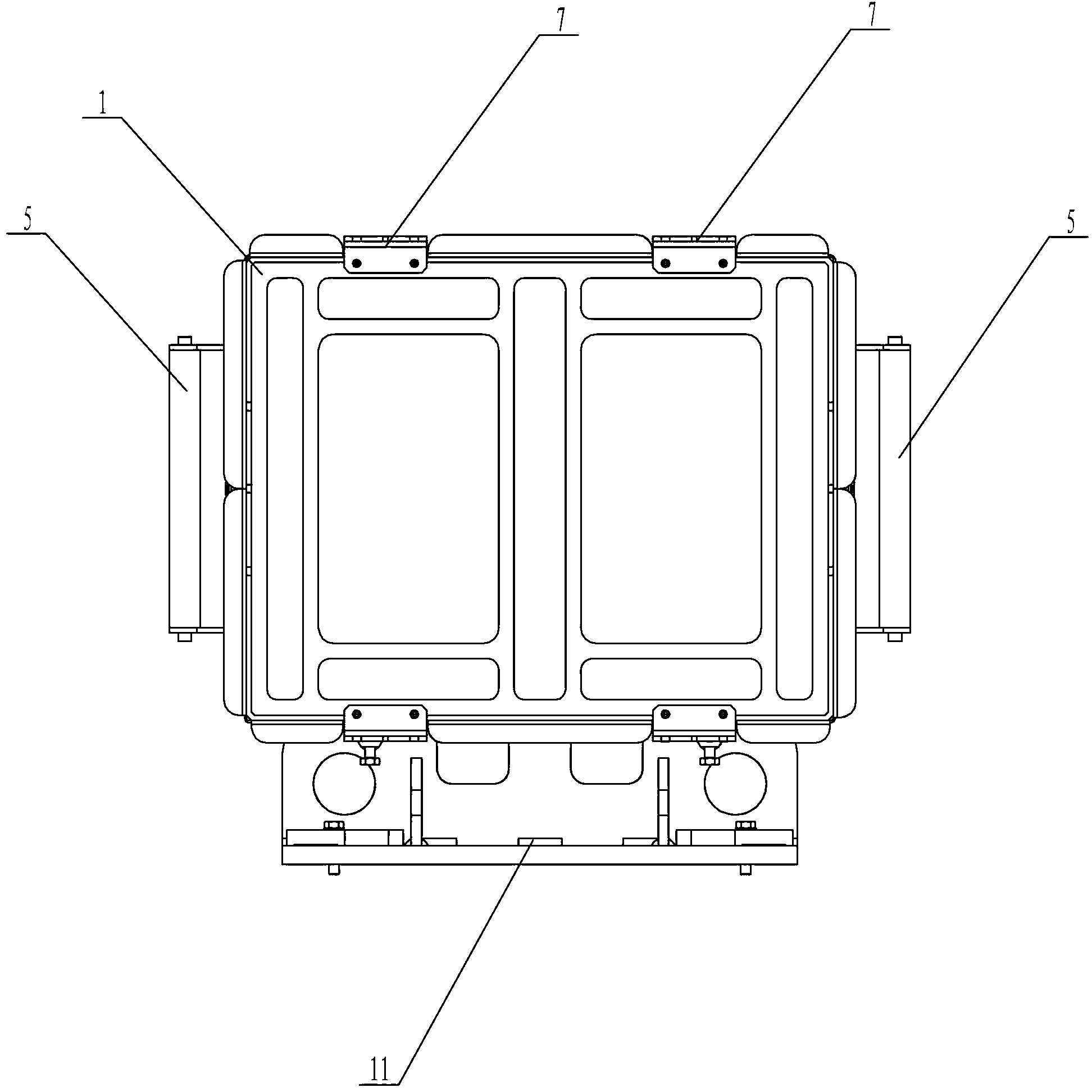

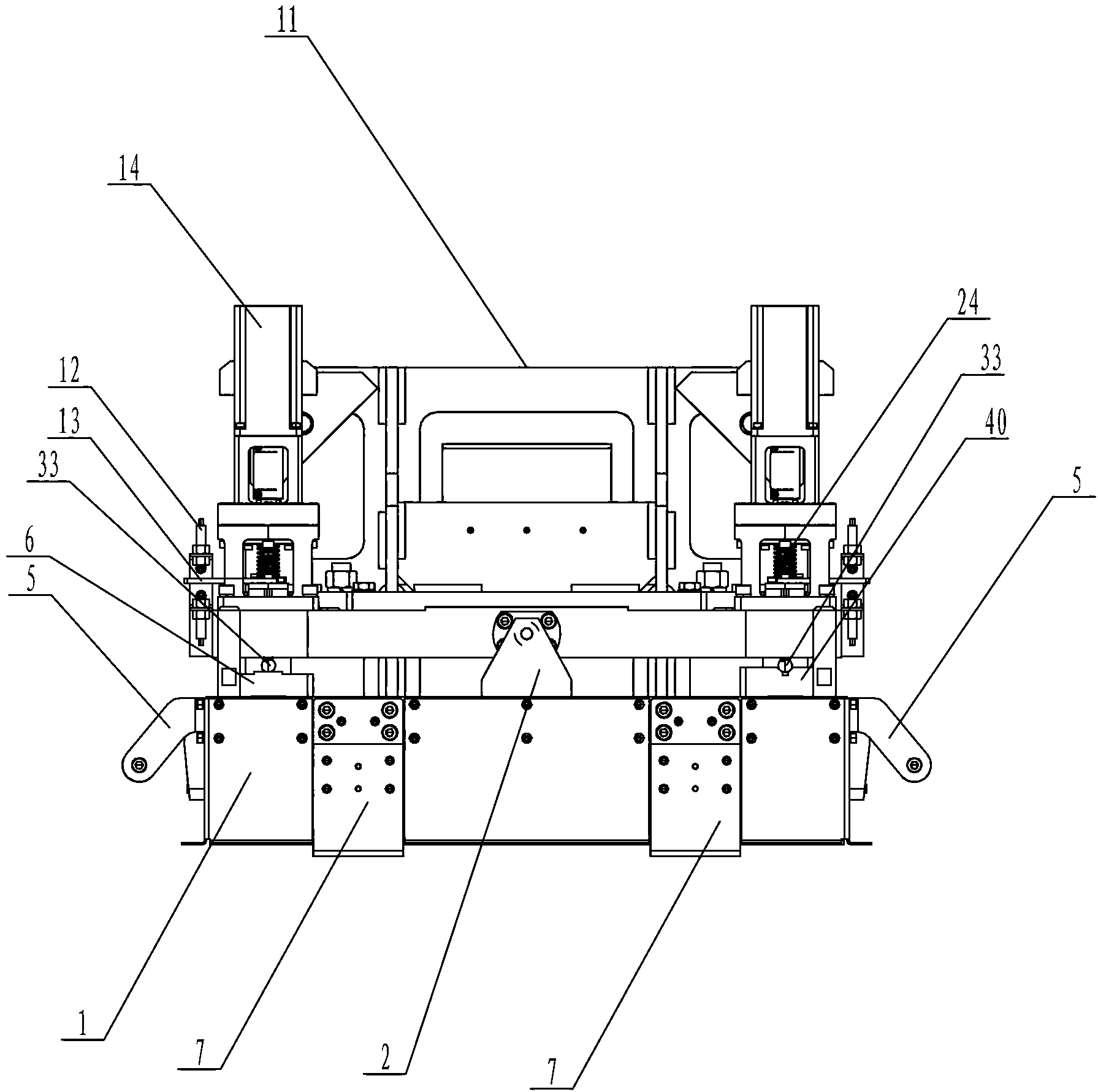

[0010] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment mode, a kind of three-point high-precision large-diameter motorized mirror frame of this embodiment includes a mirror frame assembly, a frame assembly, two micro-drive assemblies and a drive control system, and the mirror frame assembly is arranged on the front end of the frame assembly, In addition, the mirror frame assembly and the frame assembly are rotatably connected, and the two micro-drive assemblies are sequentially installed on the mirror frame assembly and the frame assembly from front to back, and the drive control system is connected and controlled by wires to control the two micro-drive assemblies.

[0011] The mirror frame assembly includes a frame body 1, a support connection block 2, a spherical support 3, a mirror crystal 4, two handles 5, a plane support block 6, a V-shaped support block 40 and four crystal pressing pieces 7, and the support connection block 2. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com