Direct current system insulation monitoring method and device

A technology of insulation monitoring and DC system, which is applied in the field of power system, can solve the problems of time-consuming and failure to detect faulty branches in time, and achieve the effect of timely detection and shortening the time for detecting faulty branches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

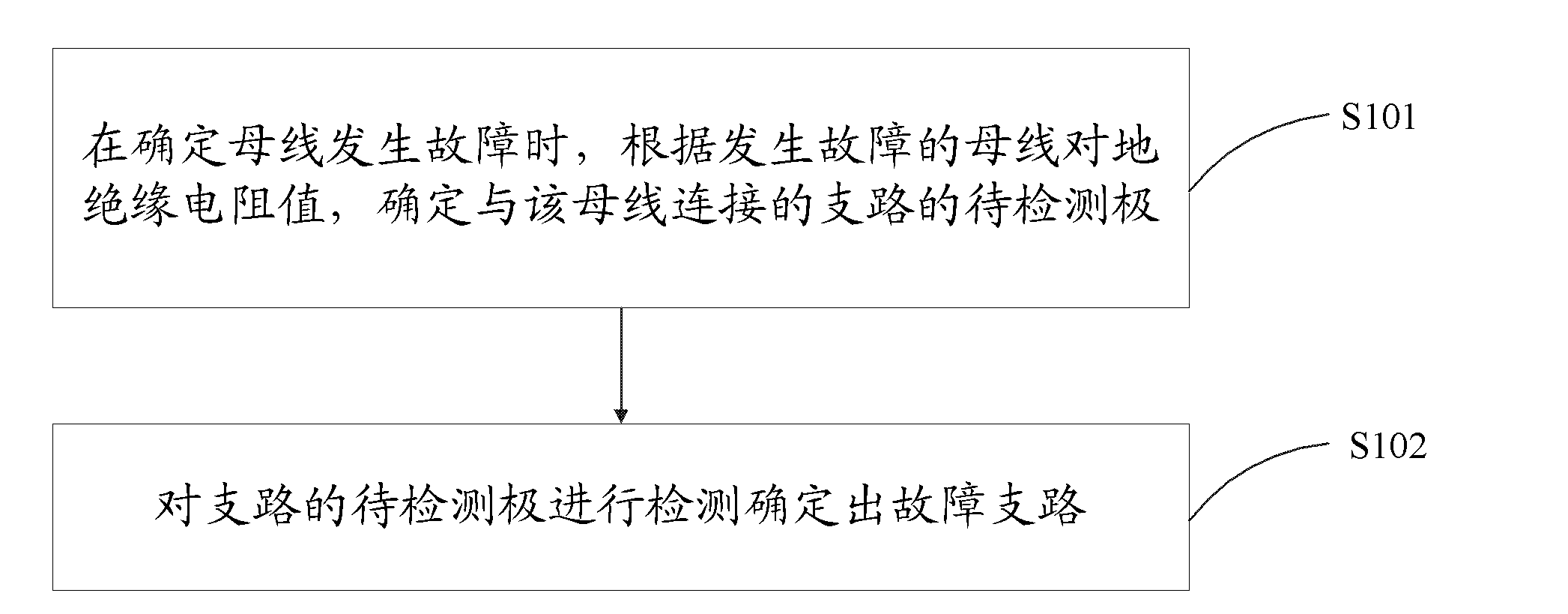

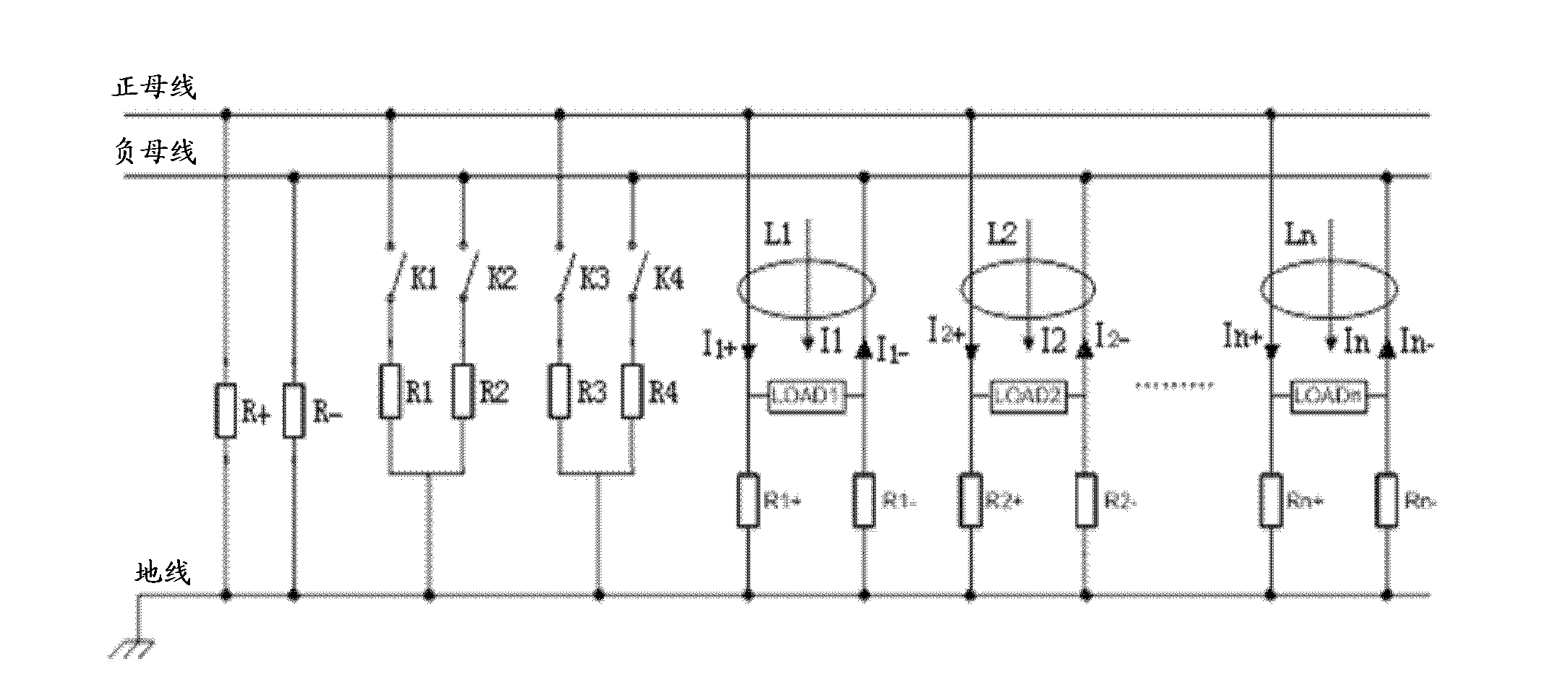

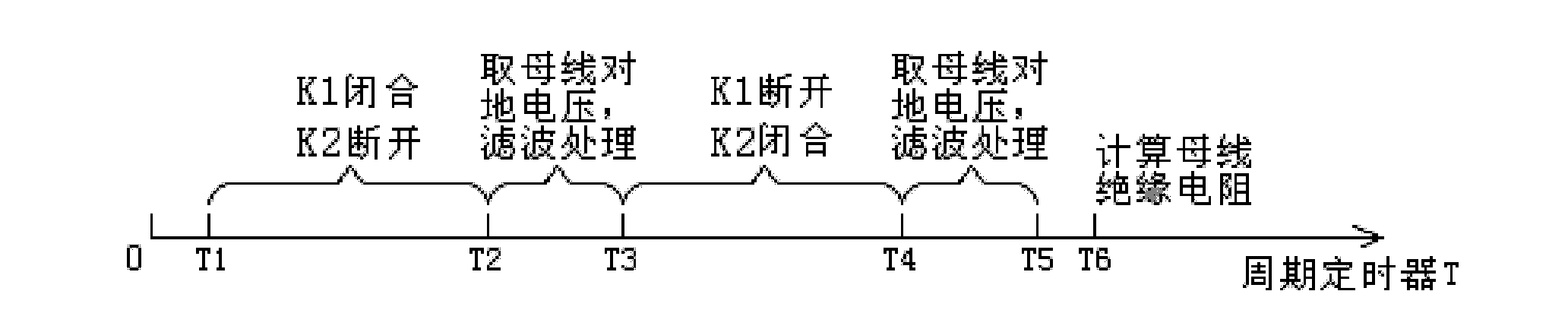

[0046] In the background technology, when the busbar of the DC system fails, the process of determining the faulty branch is time-consuming, so that the faulty branch cannot be detected in time; The pole to be detected of the branch is detected, and the pole to be detected of the branch is detected to determine the faulty branch, which avoids the need to inspect the positive and negative poles of each branch every time there is a bus fault, thus greatly The time for detecting the fault branch is shortened, and the fault branch can be detected more timely; the embodiment of the present invention determines the fault branch according to the current value of the leakage current of each branch when the positive bus or the negative bus fails. It avoids determining the faulty branch according to the positive insulation resistance value and the negative insulation resistance value of each branch, thereby greatly shortening the detection time of the faulty branch, and then can detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com