Device for detecting residual stress close to surfaces of metal materials

A technology of residual stress and metal materials, applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems of human radiation, inability to realize on-site testing, and many interference factors, etc., and achieve the effect of simplicity and intuition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiment of the present invention is described in detail below:

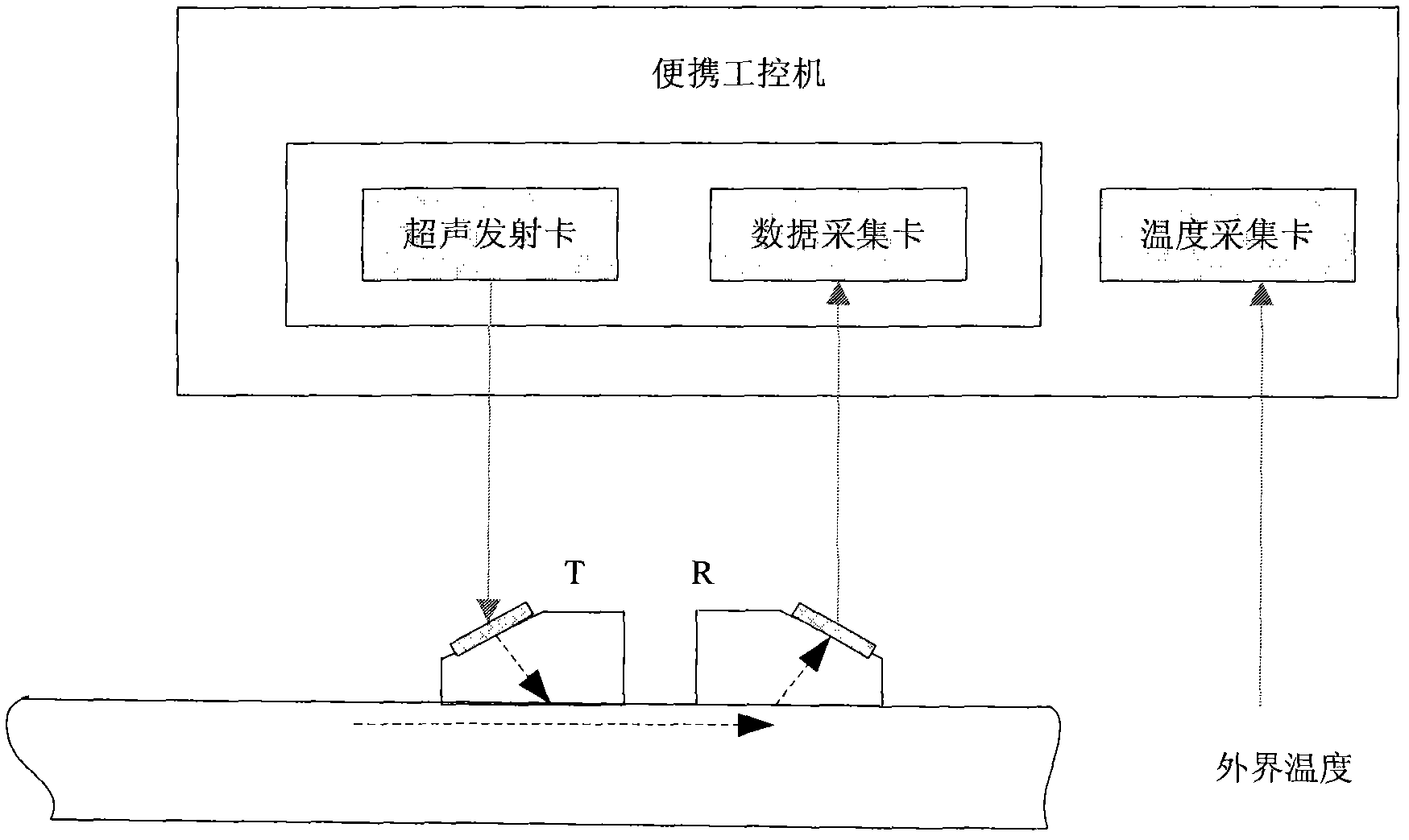

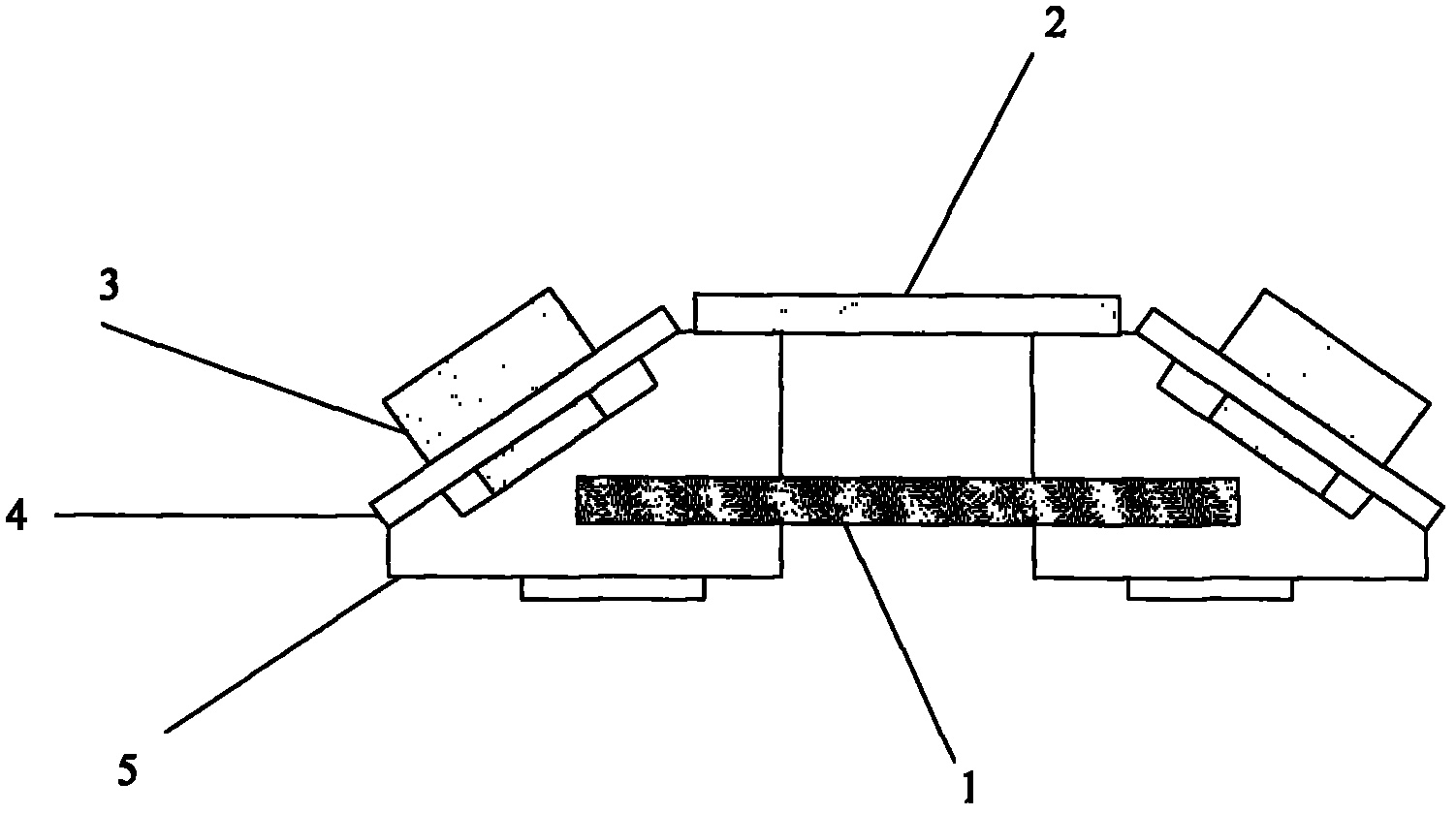

[0011] The near-surface residual stress detection device for metal materials includes two main parts, hardware and software, and auxiliary devices. like figure 1 As shown, the device of the present invention uses a computer as a platform, and mainly includes several parts such as excitation and receiving probes, ultrasonic transmitting cards, data acquisition cards, computer systems, and transmission lines. When the temperature difference is large, it will cause thermal expansion and contraction deformation of the plexiglass and the fixing plate. The temperature acquisition card is installed, and the software collects the external temperature in real time, and removes the influence of temperature changes on the deformation and sound velocity of the mechanical parts of the system, so that the system can adapt to testing under complex environmental conditions and has a wider range of applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com