Integral lifting tool for anode roasting fire wall

A technology of overall hoisting and flue wall, applied in the direction of lining repair, etc., can solve the problems of affecting the strength of the wall, cracking of the wall, and failure to use the overall hoisting device, etc., and achieve the effect of simple and ingenious structure and high hoisting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

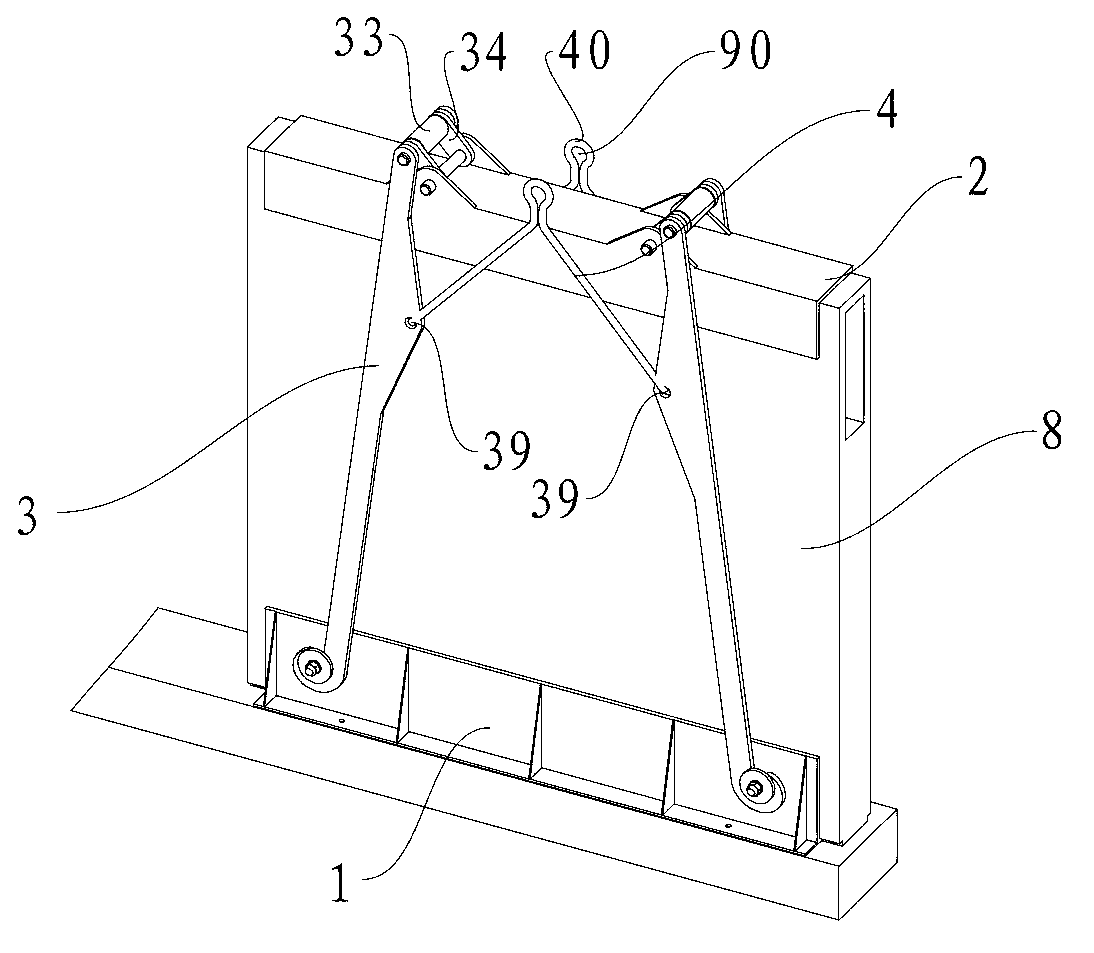

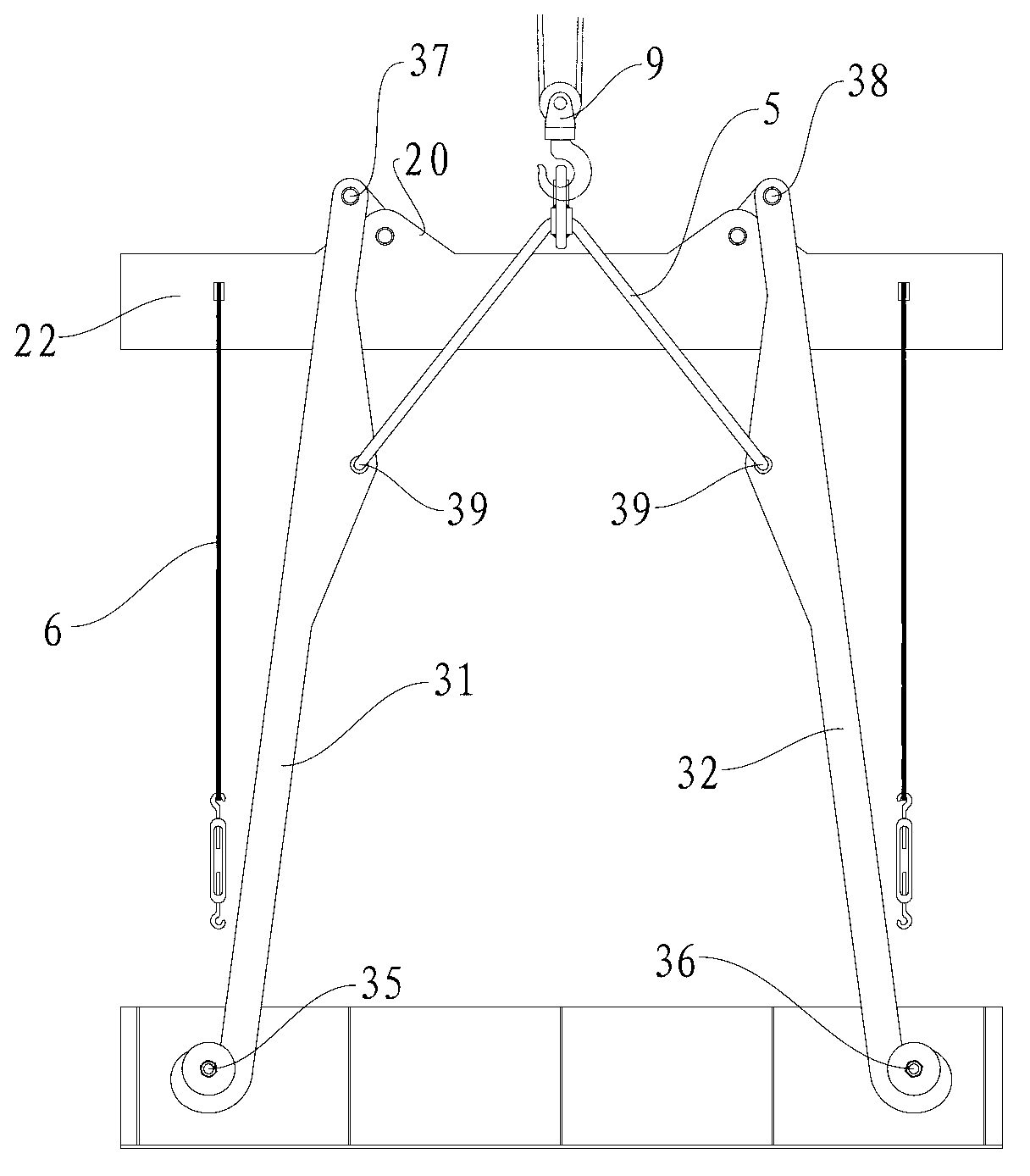

[0037] Such as figure 1 , figure 2 , image 3 As shown, the overall hoisting tool for the anode roasting flue wall of the present invention includes a lower wall support 1, an upper clamping wall panel 2 and two groups of preloading mechanisms 3 connected between the upper clamping wall panel 2 and the lower wall support 1, and the lower wall The bracket 1 includes a pair of splints 11 located on both sides of the wall accommodation space 7. The splints 11 include a vertical plate 111 for leaning against the wall and a support plate 112 opposite to the upper clamping wall plate 12. Two splints pass between the splints 11. The wall-penetrating shaft 12 is connected to each other, and the preloading mechanism 3 includes left and right frame bars 31 and right frame bars 32 arranged symmetrically. 34 is hinged on the hinge seat 20 arranged on the upper plywood 2, the lower ends of the left frame bar 31 and the right frame bar 32 are respectively hooked to the wall-through shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com