Non-welded pipeline joint of automobile air conditioner and machining method of non-welded pipeline joint

A technology for automobile air conditioners and pipeline joints, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, and sealing surface connections. It can solve problems such as increased costs, manual welding, and non-environmental protection, so as to save costs and save testing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention will be further described:

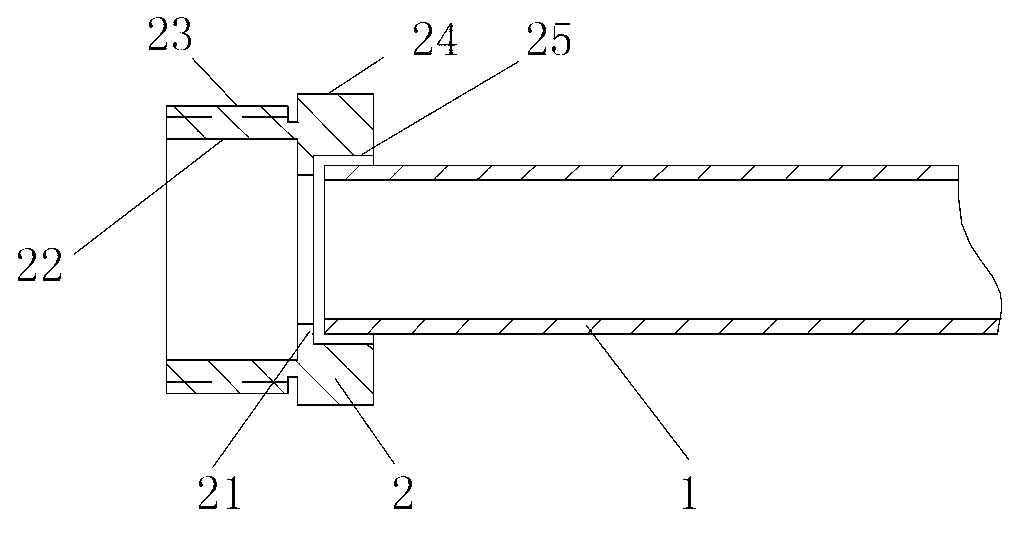

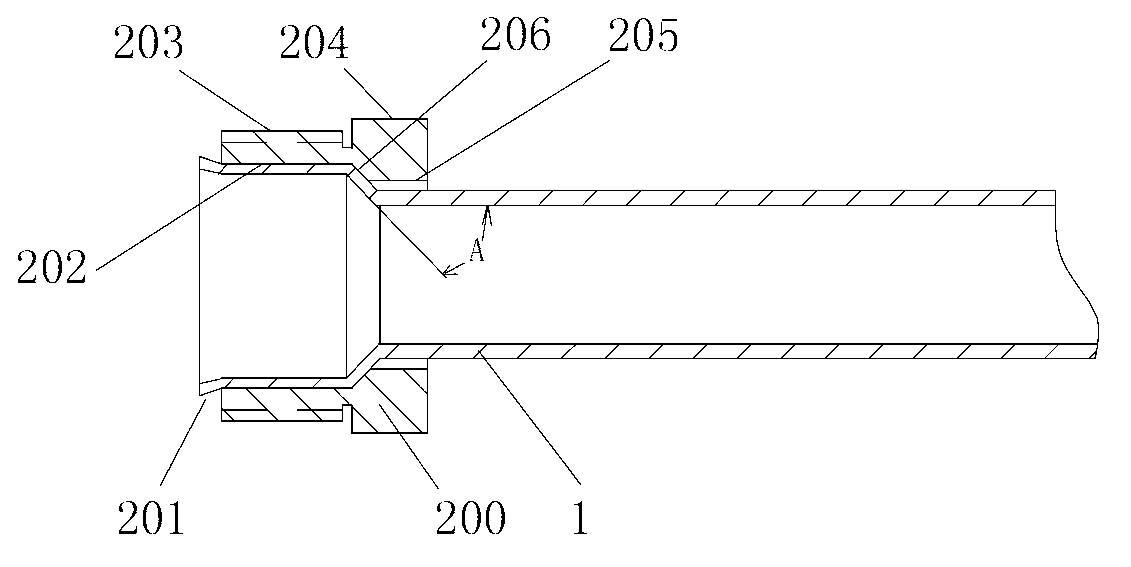

[0021] Such as figure 2 As shown, a kind of automobile air conditioner without welding pipe joint,

[0022] A non-welded pipeline joint for an automobile air conditioner, comprising: a hollow pipe 1, an external threaded joint 200, the head of the external threaded joint 200 is an external thread 203, the tail is a hexagon 204, and the inner front of the external threaded joint 200 is a large through hole 202 , the tail is a small through hole 205, the large through hole 202 and the small through hole 205 are connected by a tapered hole 206, and the outer diameter of the head of the hollow tube 1 is the same as the diameter of the large through hole 202.

[0023] The included angle A between the tapered hole 206 and the axis of the hollow tube 1 is 30-60 degrees, preferably 45 degrees.

[0024] The open end of the large through hole 202 is turned outwards from the bell mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com