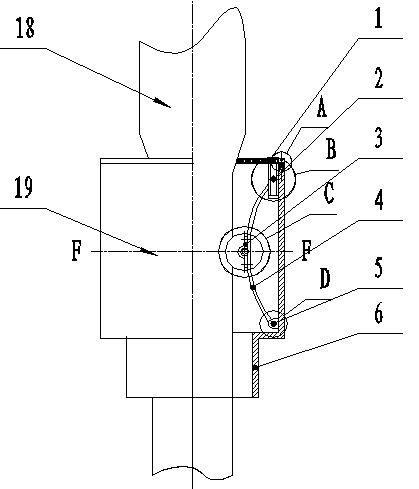

Top drive driver of rotating control head

A driver and roller technology, used in rotary drilling, rotary drilling rigs, drilling equipment, etc., can solve the problems of reduced life, rubber core wear, hidden safety hazards in drilling, waste of manpower and material resources, etc. The effect of small asynchronous grinding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

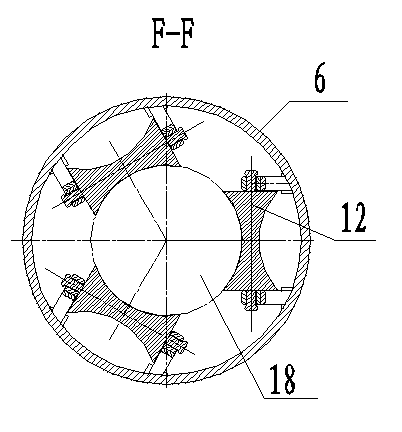

Embodiment 2

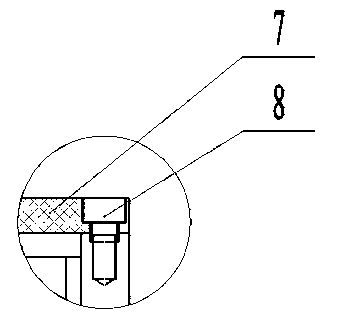

[0039] This embodiment is similar to Embodiment 1, except that the spring mechanism includes a spring, a spring seat and a bearing gland 11, and the end of the roller 12 is covered with a bearing, and the bearing is arranged in the bearing gland 11 , the bearing cover 11 is fixed on the spring seat, and the spring seat is connected to the inner wall of the housing 6 through a spring.

[0040] The top drive driver of the rotation control head of the present invention has simple structure, easy operation, convenient use, low cost, and is suitable for popularization and application; it can drive the rubber core and drill pipe to rotate synchronously during the top drive underbalanced drilling process, greatly reducing the abnormality of the rubber core. Synchronous wear and tear, improve the sealing life of the rotary control head; solve the problem of serious damage to the rubber core of the rotary control head when using top drive underbalanced drilling at present. The rubber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com