Form-removal-free cast-in-place light-weight insulated wall and construction method thereof

A technology for insulating walls and free formwork removal, which is applied to walls, building components, buildings, etc., can solve the problems of low construction efficiency, high formwork requirements, and large formwork installation and dismantling workload, and achieves less construction personnel and thermal insulation performance. Good, the effect of eliminating the mold removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

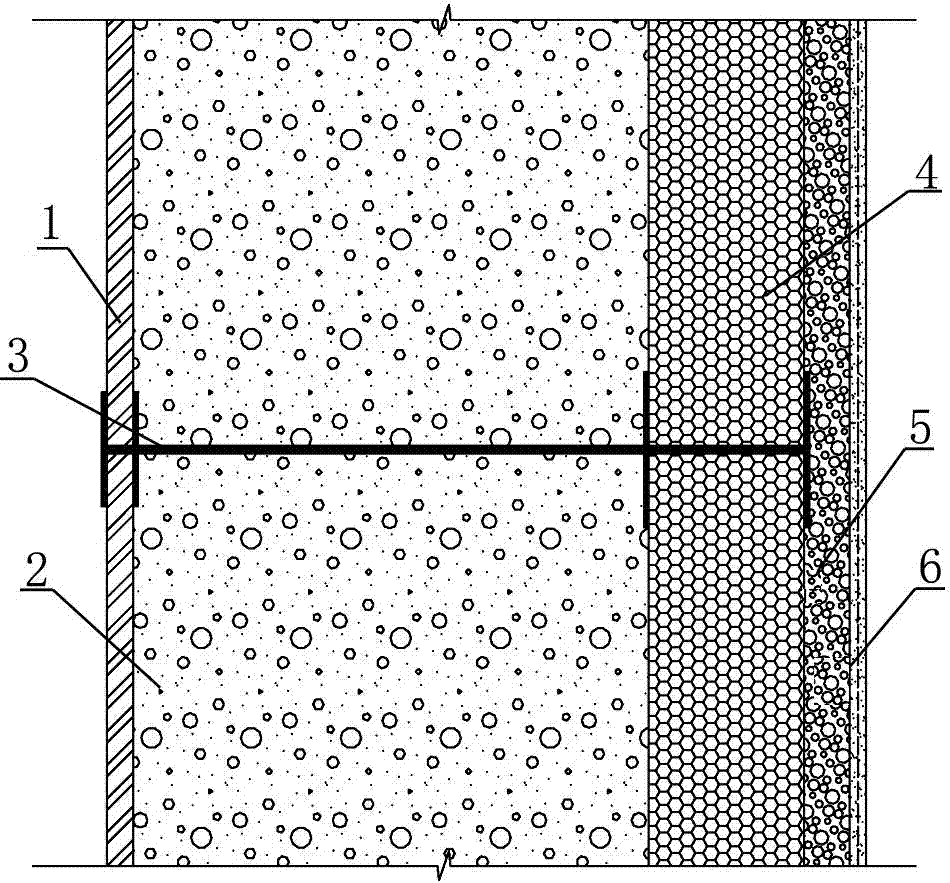

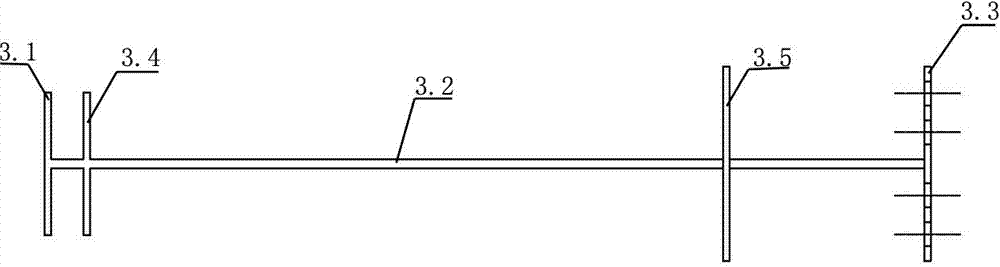

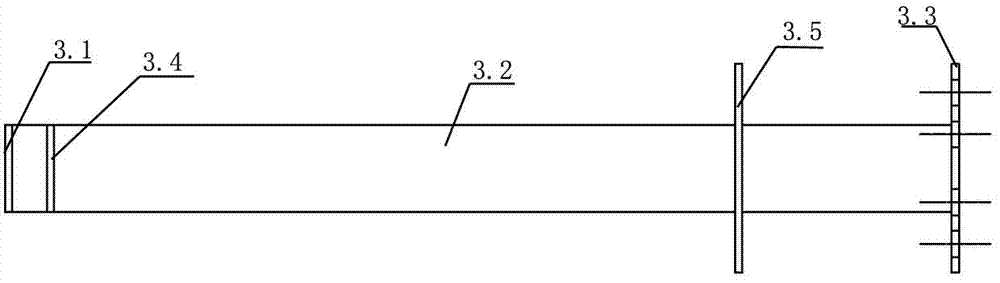

[0030] Examples see Figure 1 to Figure 5 As shown, a formwork-free cast-in-place lightweight thermal insulation wall includes a wall body, a leveling layer 5 and an anti-crack protection layer 6. The wall body is composed of an inner formwork 1, an insulation board 4 and a cast-in-place concrete layer 2 The inner formwork 1 and the insulation board 4 are arranged in parallel and facing each other, and a gap is reserved between them, and they are tied by the connector 3, and the cast-in-place concrete layer 2 is cast in the reserved gap , and bonded with the inner template 1 and the insulation board 4 as a whole.

[0031] The inner template 1 is a fiber cement board or a gypsum board.

[0032] The thickness of the inner template 1 is not less than 6mm, and the thickness of the insulation board 4 is not less than 50mm.

[0033] The concrete used in the cast-in-place concrete layer 2 is formed by mixing polyphenylene particles into lightweight foam concrete, and the weight rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com