Construction method for inhibiting frost heaving and thaw collapse of horizontally frozen end through cement-soil reinforcement method

A frost heaving and thawing settlement and construction method technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of cement consumption, manpower, machinery cost increase, construction period delay, repetitive waste, etc., to reduce construction range, reduce construction time, and reduce the effect of mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

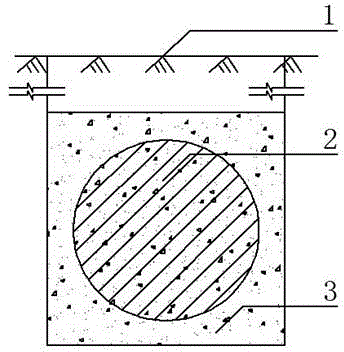

[0033] A bid section in the Dongfengjing section of the railway station of Suzhou Rail Transit Line 2, with a three-story underground structure. The geology where it is located is plain fill soil, clay layer, silty clay layer, silt, silt sand layer, silty clay layer from top to bottom from the ground 1, and the stratum that the shield tunnels through is mainly silty clay layer. The project uses deep cement mixing piles combined with horizontal freezing method to strengthen the soil at the end of the shield. Cement-soil reinforcement area 3 has a bottom surface depth of 16m, a top surface depth of 3.5m, a length of 11m along the central axis of the underground tunnel, and a length of 11.7m horizontally and vertically along the central axis.

[0034] A construction method for suppressing horizontal freezing, frost heaving and thawing settlement by cement-soil reinforcement method, and the construction steps are as follows:

[0035] 1. Construction preparation, leveling the cons...

Embodiment 2

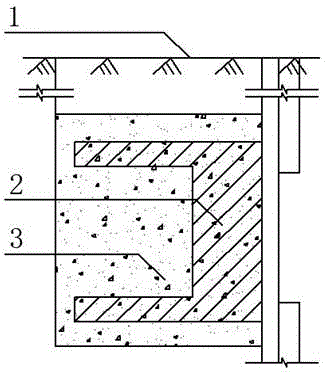

[0049] A Komatsu shield machine is used for excavation construction in a tender section of Nanjing Metro Line 3. The total length of the shield machine is 9.33m, the outer diameter of the tunnel is 6.2m, and the diameter of the portal is 6.7m. The formation within the reinforcement range of the starting end starts from the ground 1, and from top to bottom is silty clay, silt-sand interlayer, and silt-fine sand. The silty clay and silt-sand interaction layer has weak water permeability, and the permeability coefficient of the silt-fine sand layer is 10-3cm / s, which belongs to the water-permeable formation, and the groundwater has weak pressure resistance. The strata within the tunnel body are silt and fine sand, and the center of the tunnel door is buried at a depth of 18.98m. Both the entry and exit holes are reinforced with horizontal freezing. The depth of the bottom surface of the cement-soil reinforcement area 3 is 25m, the depth of the top surface is 12m, the length alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com