Drafting device, spinning unit and spinning machinery

A drafting device and drafting technology, applied to spinning machines, free-end spinning machines, continuous winding spinning machines, etc., can solve the problems of difficult connection and blocking, and achieve the effect of reliable suction and leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, embodiments of the invention will be described with reference to the drawings.

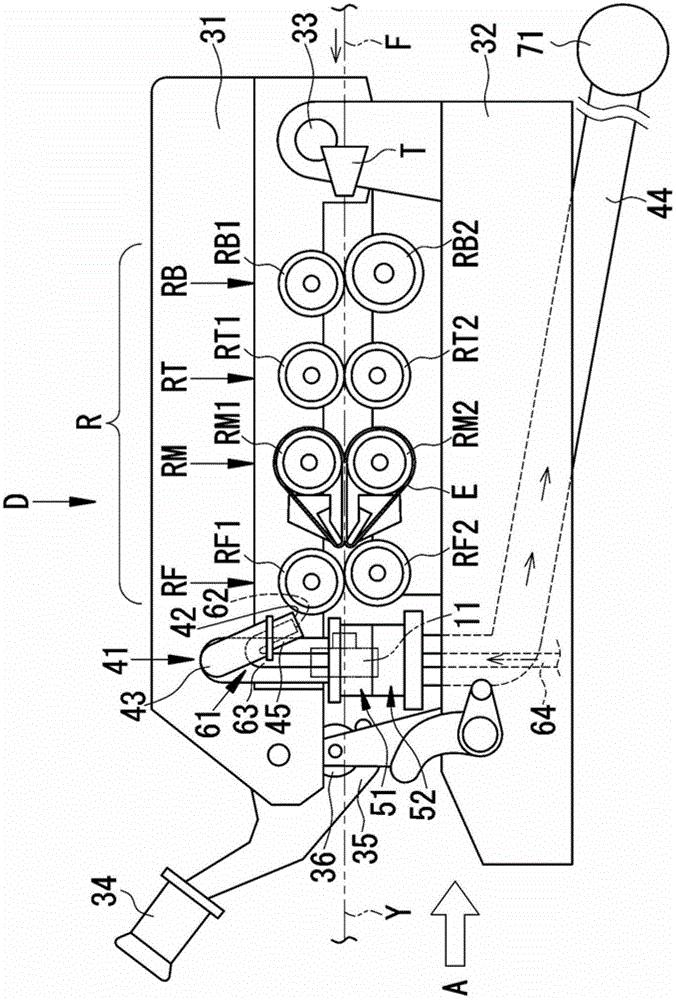

[0040] use Figure 1 to Figure 6 B describes the drafting device D of the first embodiment of the present invention, the spinning unit U and the spinning machine M equipped with the drafting device D.

[0041] First, the outline of the spinning machine M will be described. In addition, in this specification, "upstream" and "downstream" mean upstream and downstream in the movement direction of the fiber bundle F and the spun yarn Y in the spinning unit U.

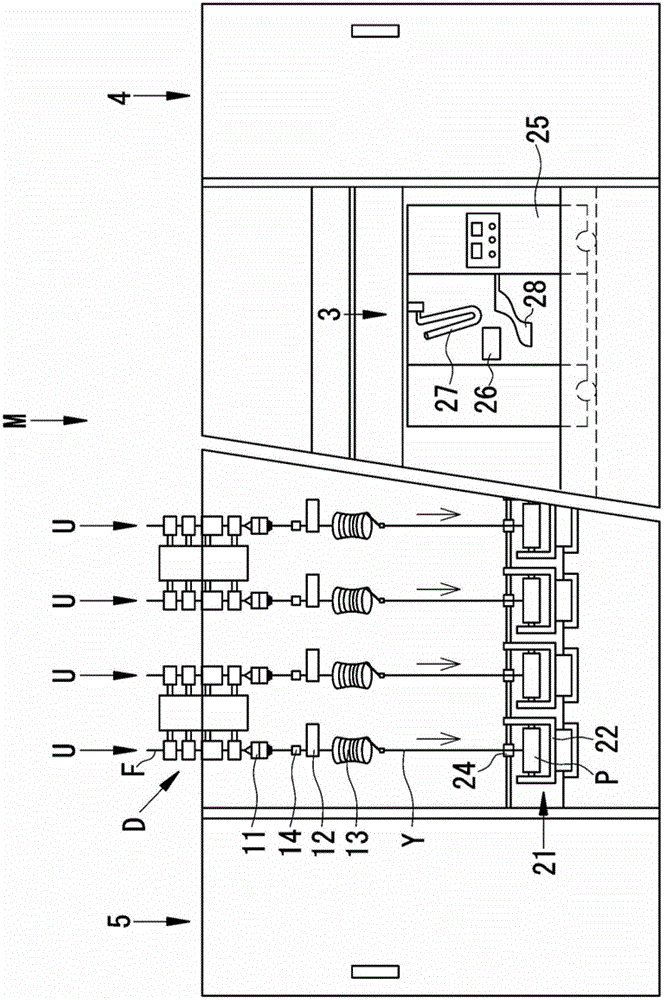

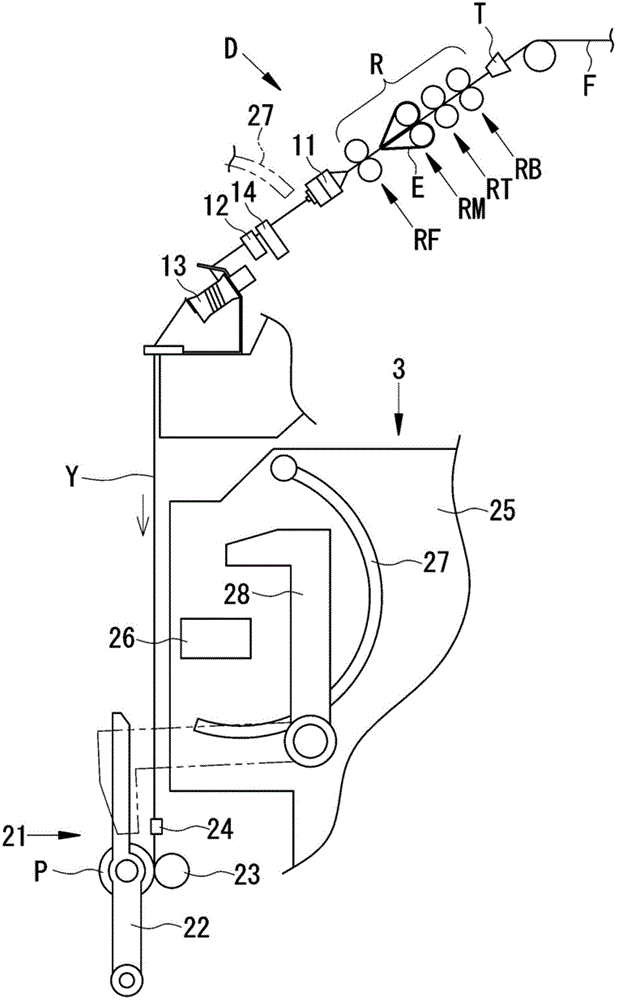

[0042] Such as figure 1 and figure 2 As shown, the spinning machine M includes a plurality of spinning units U, a splicing trolley 3, a blower box 4, and a power box 5 arranged in parallel. Each spinning unit U includes a draft device D, a spinning device 11, a yarn clearer 12, a yarn slack eliminating device 13, and a winding device 21.

[0043] Such as figure 2 As shown, the drafting device D drafts the fiber bundle (sliver) F supplied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com