Bottle turning mechanism of filling machine

A filling machine and bottle filling technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as affecting filling efficiency, increasing production costs, and inconvenient use. The effect of normal filling and convenient access to the bottle mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

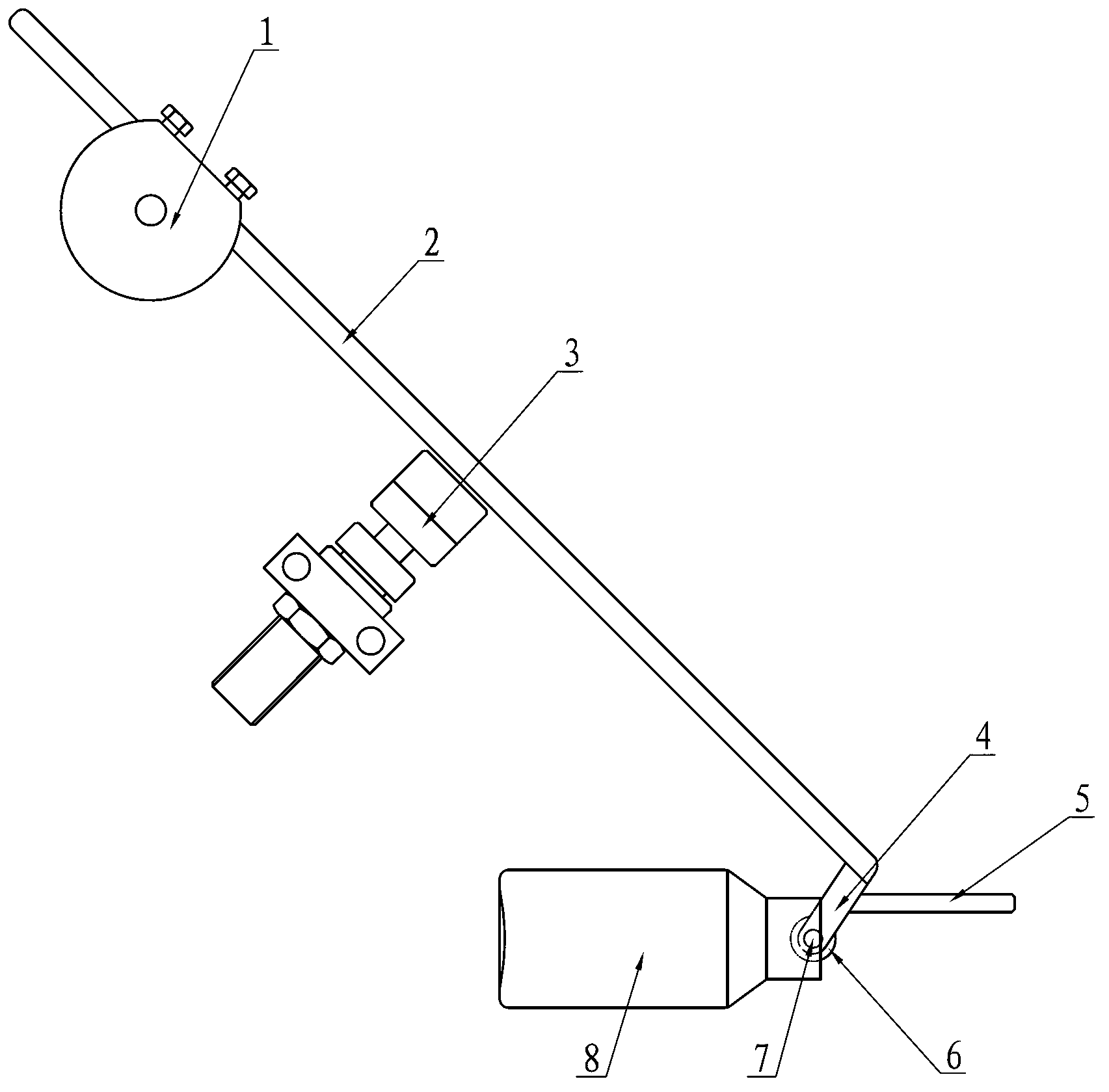

[0016] Embodiment 1: a kind of bottle turning mechanism of filling machine, as figure 2 As shown, it includes an adjustable pressure rotary cylinder 1, a bottle lever 2 and a buffer 3. The upper section of the bottle lever 2 is fixedly connected with the rotating shaft of the adjustable pressure rotary cylinder 1, and the buffer 3 is installed in the middle of the bottle lever 2. , the bottom end of the bottle opening bar 2 is provided with a bottle mouth bar 4, the installation angle requirement of the bottle mouth bar 4 and the bottle opening bar 2 is 100°, the length of the bottle mouth bar 4 is 6cm, and the bottle mouth bar 4 is provided with There is an anti-jam rod 5, which is horizontally fixed on the bottle mouth rod 4, the length of the anti-jam rod 5 is 80 mm, and the distance from the lower end of the bottle mouth rod 4 to the confluence of the anti-jam rod 5 and the bottle mouth rod 4 It is 1 / 2~1 of the bottleneck diameter of the bottle body 8 to be filled, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com