Conveying system for electrophoretic painting production of ultralong heavy workpieces

A conveying system and heavy-duty technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of super-long workpiece shift production and storage difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

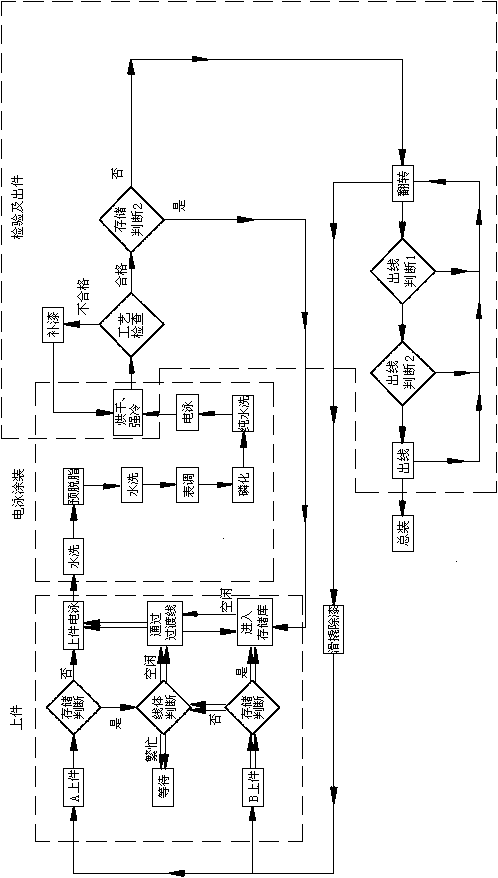

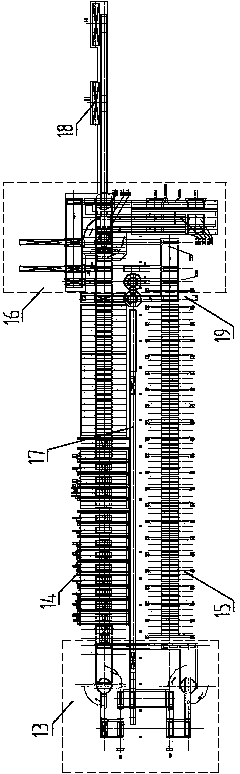

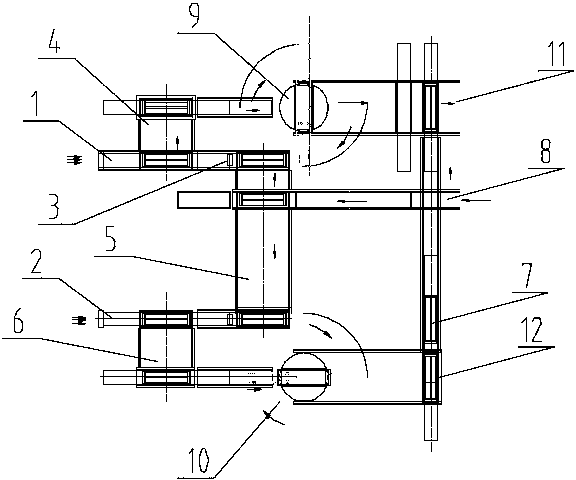

[0010] Control attached figure 2 , the electrophoretic paint production and conveying system for super long and heavy workpieces, its structure includes an upper work area 13 (on-line conveying line), an electrophoretic coating line 14, a three-dimensional warehouse 15, a lower work area 16, a skid removal paint line 17, and an assembly Line 18 and B storage station 19, wherein the upper work area 13 is connected with the electrophoretic coating line 14, the three-dimensional warehouse 15 and the skid paint removal line 17 respectively, and the electrophoretic coating line 14, the three-dimensional warehouse 15 and the skid paint removal line The line 17 is respectively connected to the next work area 16, the next work area 16 is connected to the assembly line 18, and the electrophoretic coating line 14 is connected to the three-dimensional warehouse 15 in parallel;

[0011] Described three-dimensional warehouse 15 adopts a commonly used three-dimensional warehouse, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com