Die seat for carrying out pressing forming on tile

A press-forming and die-seat technology, which is applied in the field of die-seats for brick and tile press-forming, can solve the problems of insufficient magnetic attraction force of the support base, difficult replacement of the support base, easy deformation of the support base, etc., so as to reduce the difficulty of line maintenance and reduce the use cost. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

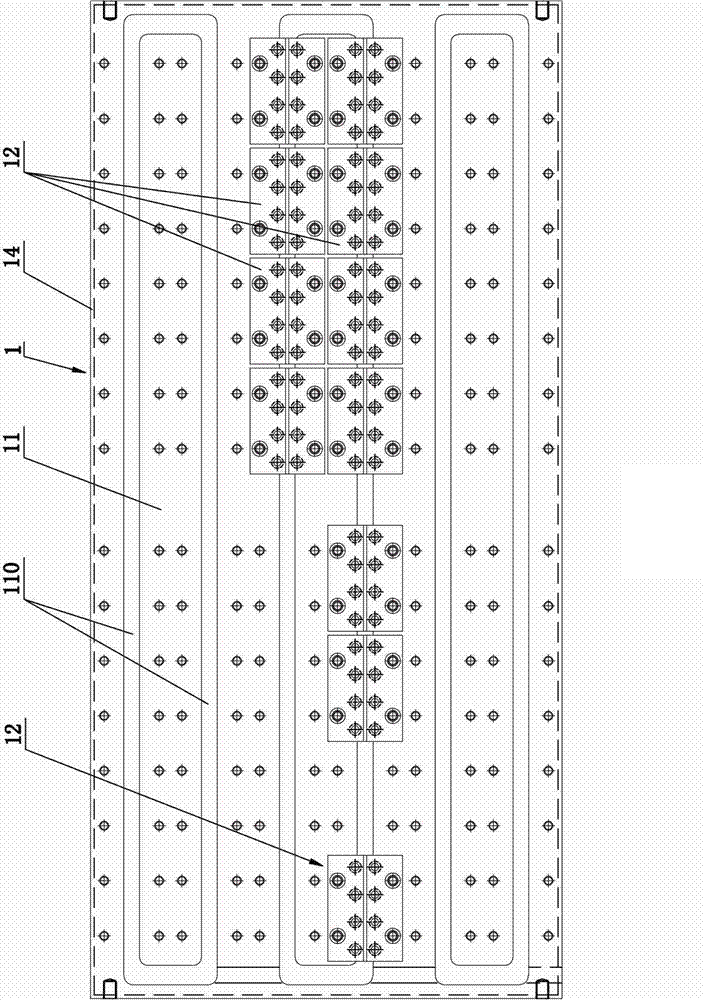

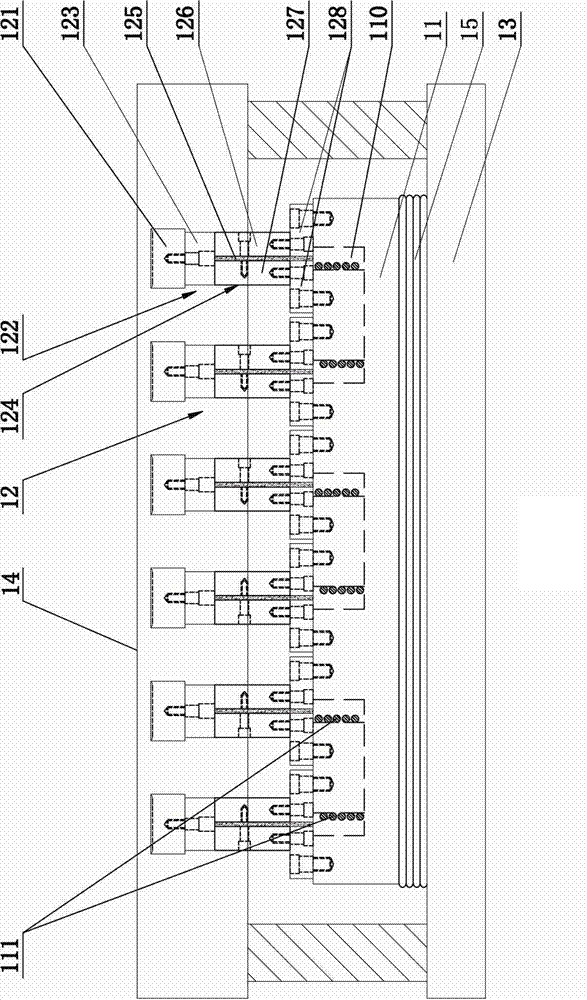

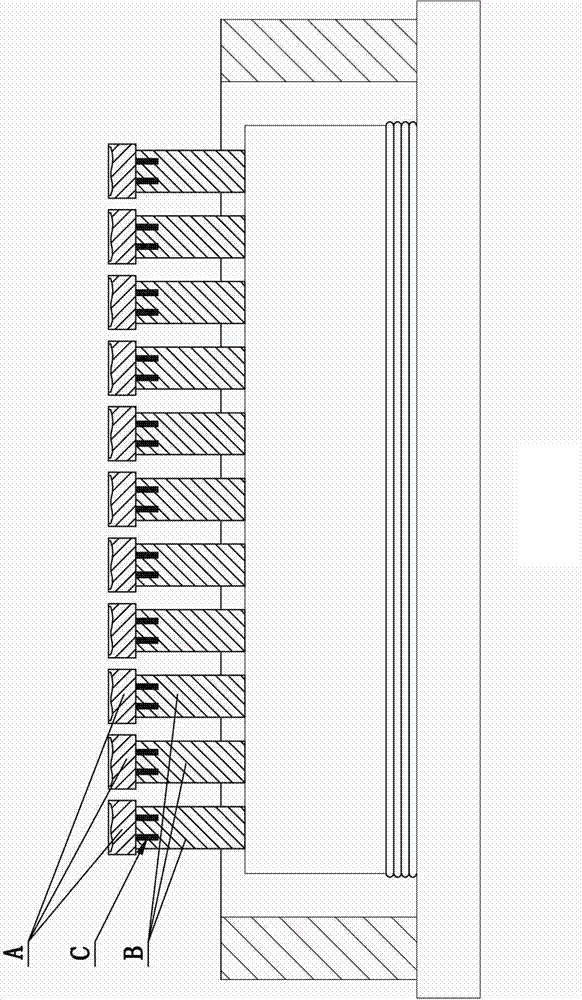

[0016] refer to figure 1 , figure 2 , a mold base for pressing bricks and tiles, including a mold base body 1, the mold base body 1 includes a magnetic plate 11 and several lower mold mechanisms 12 detachably fixed and assembled on the top surface of the magnetic plate 11 by bolts, The bottom of the magnetic suction plate 11 is equipped with a supporting base plate 13, and the bottom of the magnetic suction plate 11 is also equipped with a drive mechanism to drive the overall up and down movement of the magnetic suction plate 11. Between the magnetic suction plate 11 and the bottom plate 13 There is a dustproof cover 15 made of leather, cloth or rubber that can be stretched longitudinally. The dustproof cover 15 can prevent the powder from entering, and can also play a buffer role when the magnetic suction plate 11 is pushed; The top surface of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com