Method and device for aiming at and fetching columnar micro-part on the basis of microscopic vision

A technology of microscopic vision and micro-parts, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of complex operation process and low efficiency, achieve the effect of simplifying the operation process, avoiding cumbersome processes, and improving the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

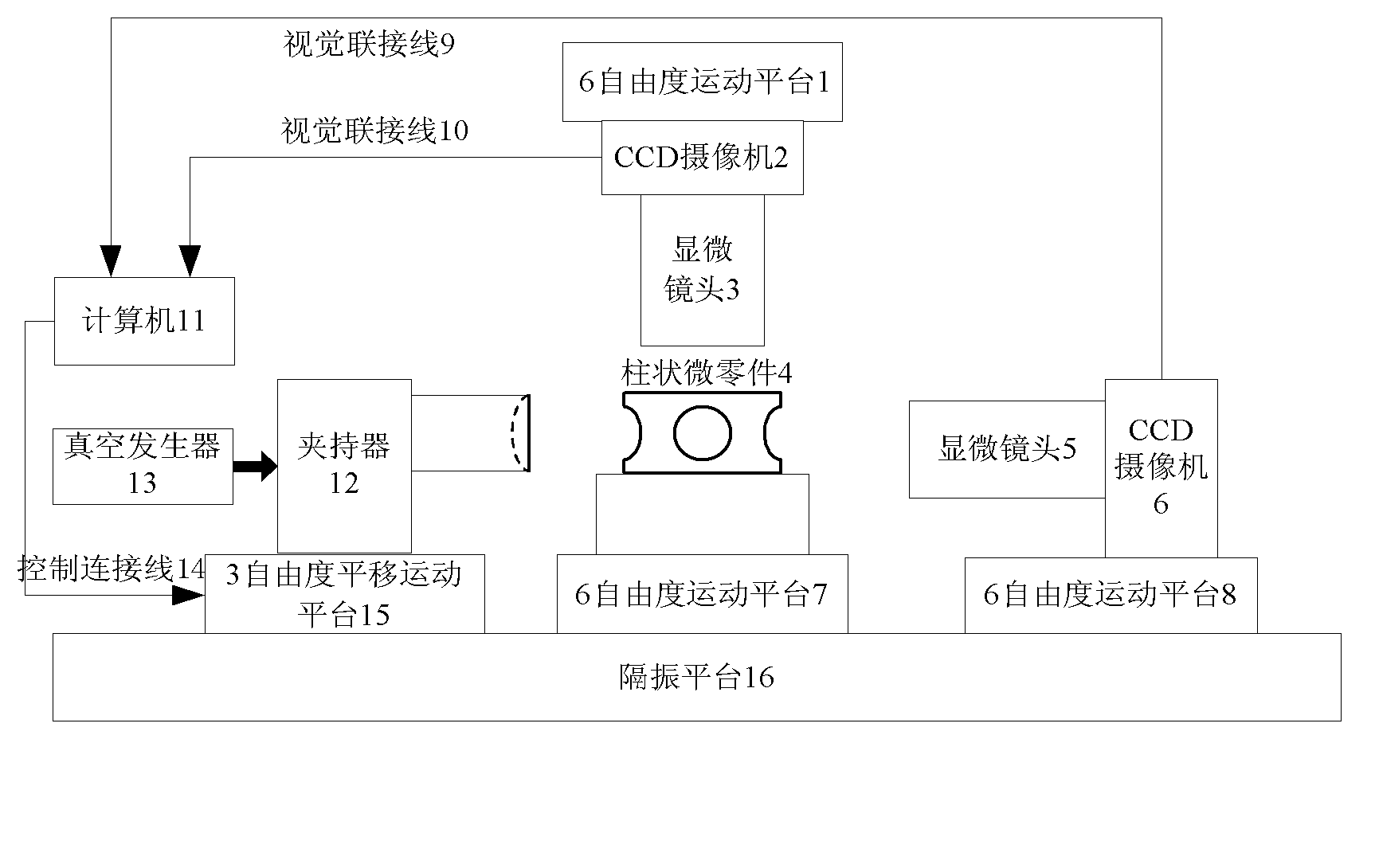

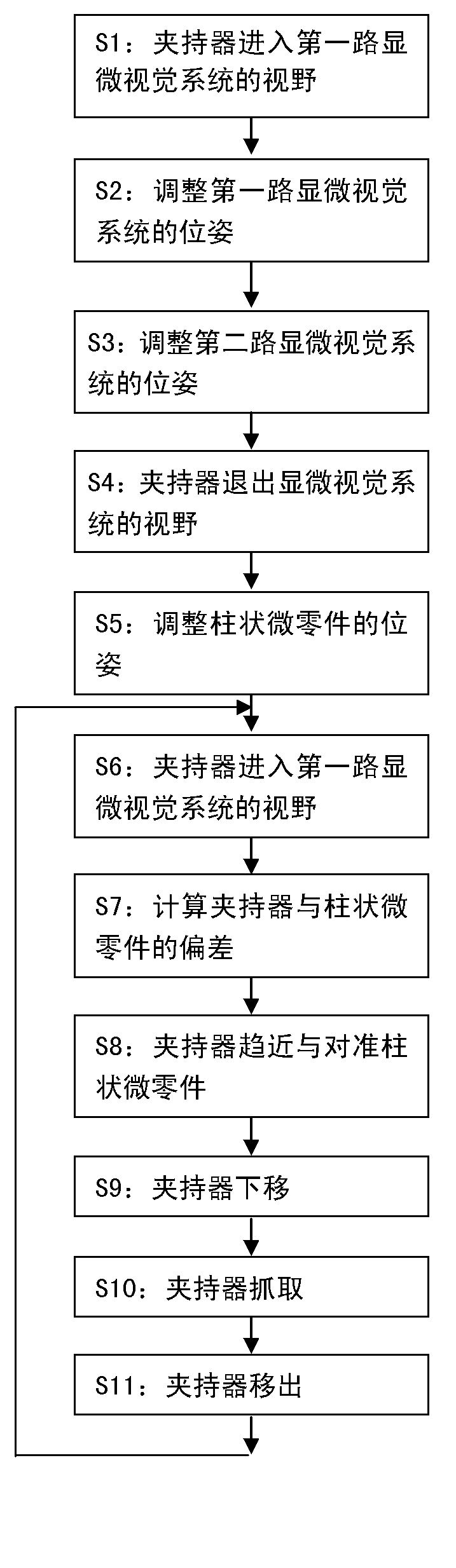

[0027] figure 1 It is a schematic diagram of the device for aligning and grabbing columnar micro parts based on microscopic vision of the present invention, such as figure 1 As shown, the device includes: 6-DOF motion platform 1, the first micro-vision system, columnar micro parts 4, the second micro-vision system, 6-DOF motion platform 7, 6-DOF motion platform 8, vision Connection line 9, vision connection line 10, computer 11, gripper 12, vacuum generator 13, control connection line 14, 3-DOF translational motion platform 15, vibration isolation platform 16, wherein:

[0028] The 6-DOF motion platform 1, the 6-DOF motion platform 7, the 6-DOF motion platform 8 and the 3-DOF translation motion platform 15 are all instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com