Rapid nondestructive dismantling device for liquid crystal display framework

A liquid crystal display, fast technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unsafe, unfavorable maintenance and recycling, affecting the appearance of the frame, etc., to achieve good reusability, high-efficiency dismantling in large quantities , The effect of dismantling operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

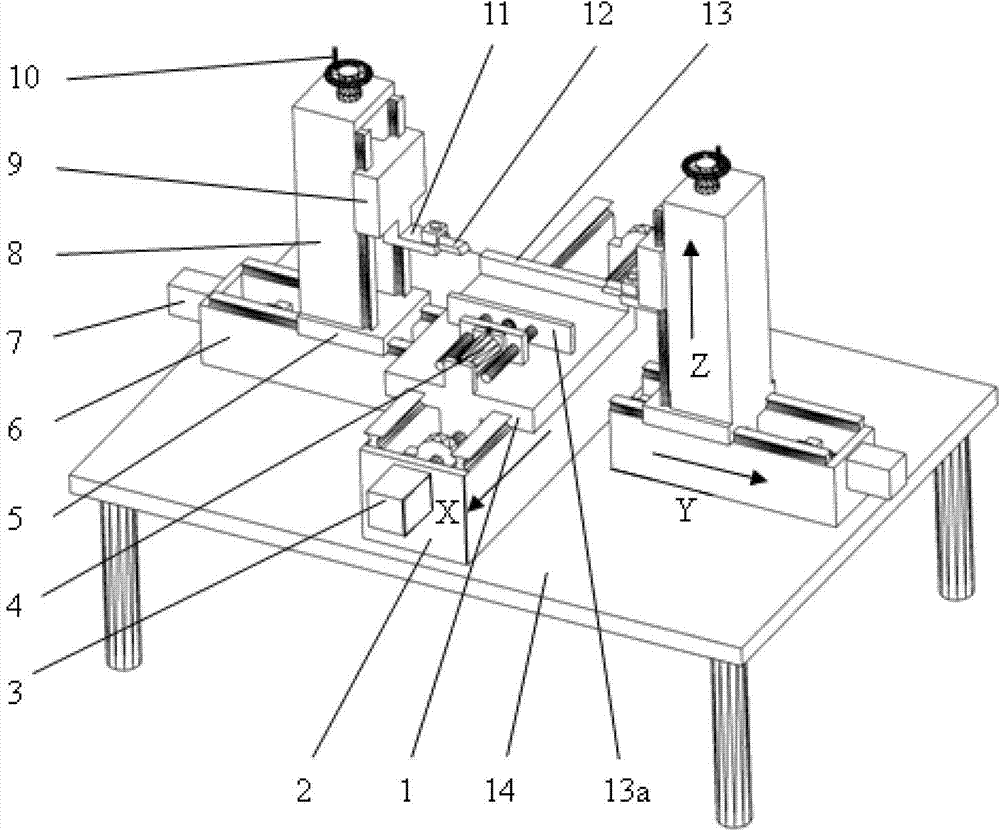

[0025] The structure of the device for quick and nondestructive disassembly of the liquid crystal display frame in this embodiment is set as follows:

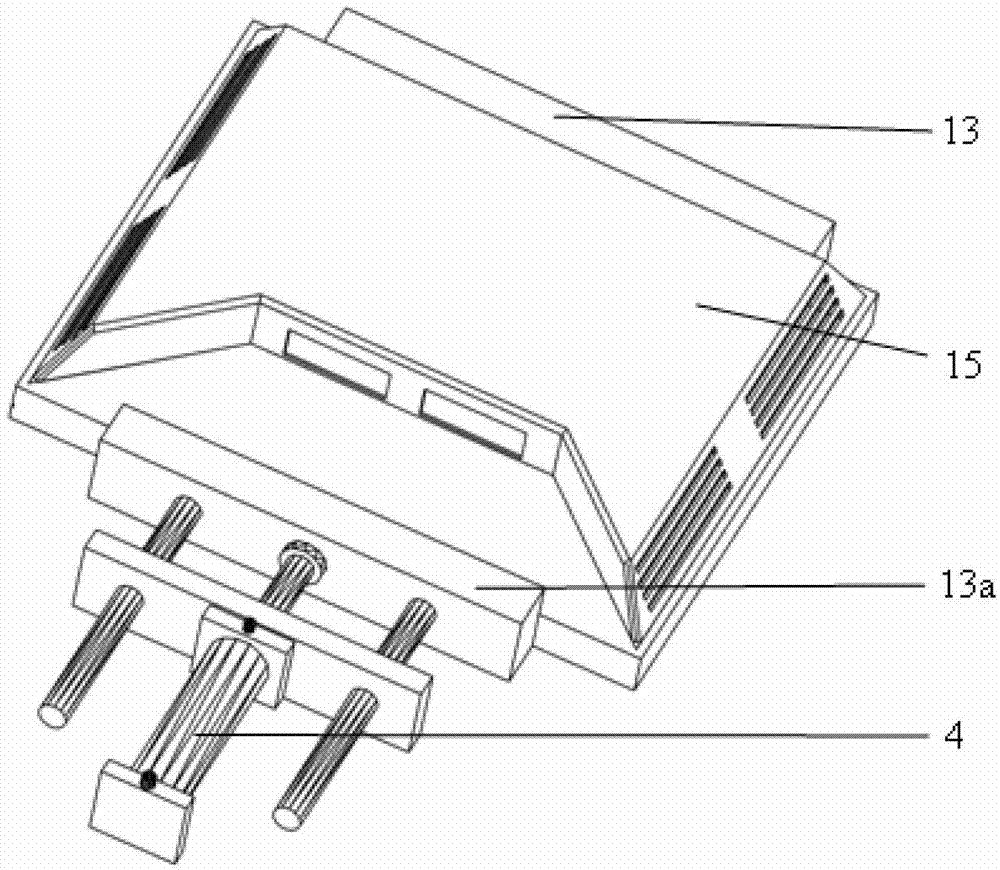

[0026] Such as figure 1 with figure 2 As shown, the clamping unit is provided with an X-direction sliding table on the worktable 14, a fixture platform 1 that moves with the X-direction sliding table in the X direction is provided on the X-direction sliding table, and a limit position is provided on the fixture platform 1. The plate 13 and the clamping plate 13a that can move along the X direction, the disassembled liquid crystal display 15 is clamped between the limit plate 13 and the clamping plate 13a with its symmetrical two sides. The clamping plate 13a is set on the clamp platform 1 Driven by cylinder 4 with linear guide rod.

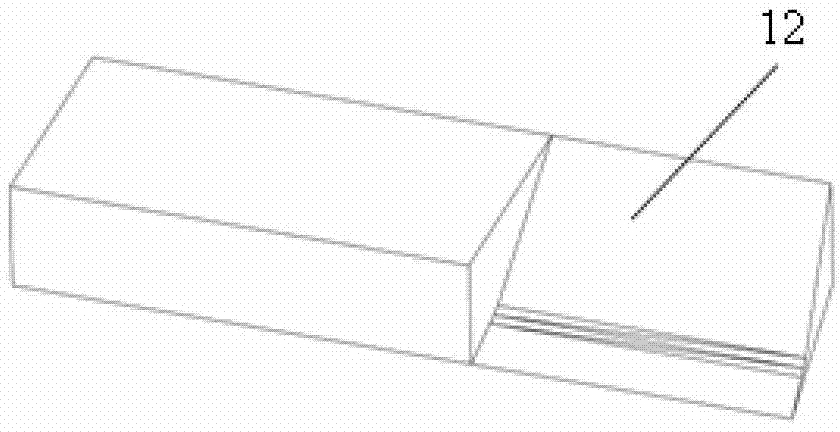

[0027] Such as figure 1 , image 3 with Figure 4 As shown, the disassembly unit is to set a Y-direction slide on the worktable 14 on the side of the X-direction slide, a Z-direction slide is set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com