Disassembly and assembly system and disassembly method of vibrating ore drawer motor

A mining machine, square technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of dangerous working environment and working state, limited space for disassembling and assembling the motor, and heavy weight of the motor, so as to eliminate potential safety hazards , increase safety and reliability, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

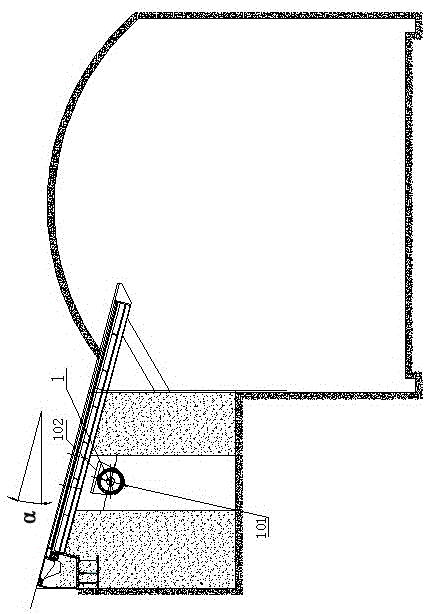

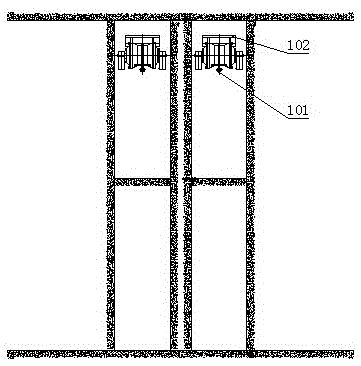

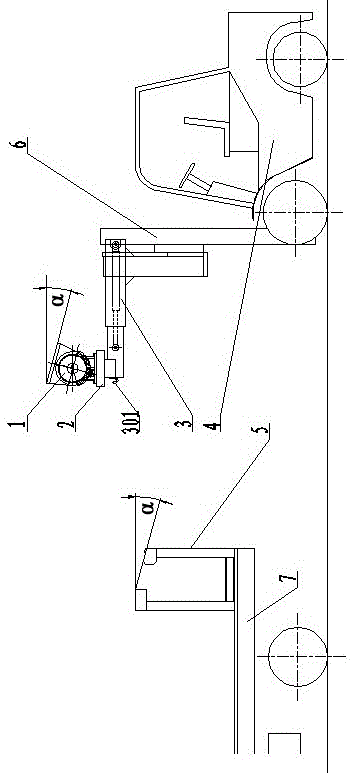

[0041] Such as Figure 1-a to Figure 4 As shown, the vibrating ore drawing machine motor disassembly system is composed of a self-propelled disassembly vehicle 4 assembled with a telescopic arm 3 and a motor clamping device 2, and a motor loading frame 5 for being arranged on a carrier vehicle 7.

[0042]Wherein, a vertical mast 6 is installed in front of the chassis of the self-propelled dismantling vehicle 4, the support of the telescopic arm 3 is installed on the vertical mast 6, and the vertical mast 6 is additionally provided with The lifting cylinder that drives the telescopic arm 3 to reciprocate up and down (omitted in the figure, a lifting cylinder structure integrated with the vertical mast can be used, which is commercially available), and the motor clamping device 2 is sent to the motor 1 The height where the oil inlet and outlet of the hydraulic cylinder in the telescopic arm 3 is connected with the hydraulic valve group arranged at the lower part of the cab of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap