Electric screw press control system and electric screw press control method

A technology of electric screw and control system, which is applied to the driving device of presses, manufacturing tools, forging presses, etc. It can solve the problems of prolonged recovery time of sliders, shortened service life of molds, and connection failures, so as to eliminate downtime and prolong The effect of improving the service life and improving the overall reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

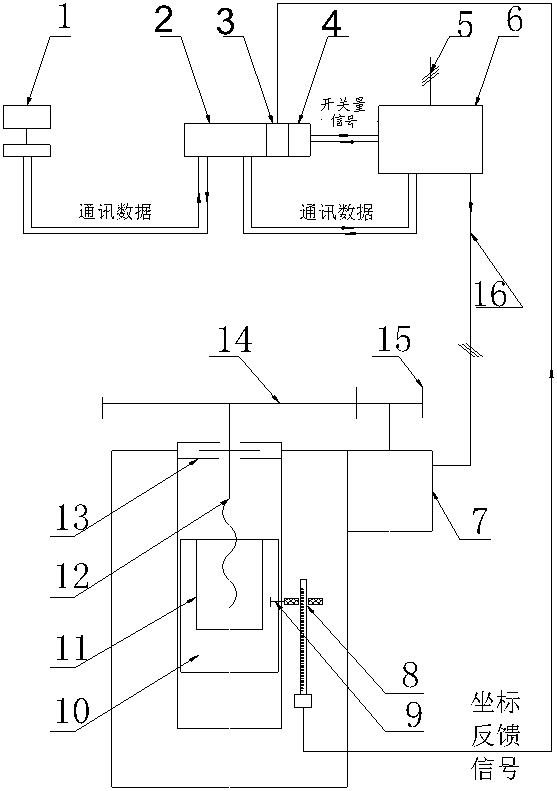

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] see figure 1 As shown, the figure shows the structure of a control system for an electric screw press provided by an embodiment of the present invention. For ease of description, only the parts related to the embodiment of the present invention are shown.

[0019] Such as figure 1 As shown, a control system for an electric screw press includes a main motor 7 that drives the slider 10 of the electric screw press to move linearly up and down, a PLC controller 2 that controls the operation of the main motor 7 and connects the main motor through a power cable 16 7, a motor driver 6 connected to the PLC controller 2 for setting and collecting data; also includes a slider position detection device 8 for detecting the current coordinate position of the slider 10;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com