A tool head for incremental forming that can be used in both directions

A technology of gradual forming and forming head, which is applied in the field of improvement of forming tool head for gradual forming of sheet metal, which can solve the problems of primitive operation, few and troublesome progressive forming tool heads, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

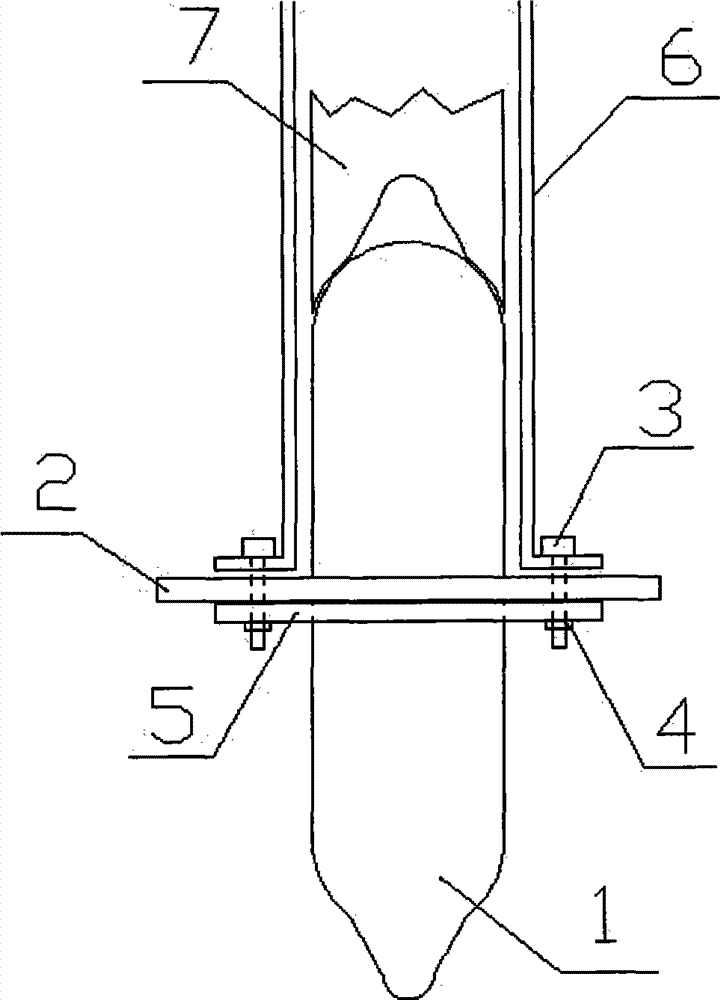

[0011] Such as figure 1 A tool head for progressive forming that can be used in two directions is shown, including a two-way forming head (1), a rotating shaft (2), a stop screw (3), a lock nut (4), a backing plate (5), Protective outer cover (6) and forming head support (7), one end of described two-way forming head (1) is a ball indenter with a radius of 15mm, and the other end is a ball indenter with a radius of 4mm. Open a circular through hole in the middle of the two-way forming head (1), the diameter of the circular through hole is the same as the diameter of the rotating shaft (2), pass the rotating shaft (2) through the above-mentioned circular through hole and the two-way forming head (1) Make a gapless connection. The two-way forming head (1) is fixed by a tightening mechanism to prevent it from rotating. The locking mechanism is composed of stop screw (3), lock nut (4), backing plate (5), protective cover (6); backing plate (5) has a diameter larger than the two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com