Preparation method of fuel battery catalyst carrier WO3 (Tungsten Trioxide)

A technology of catalyst carrier and fuel cell, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., to achieve the effect of simple and easy control, wide application value, excellent thermal stability and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

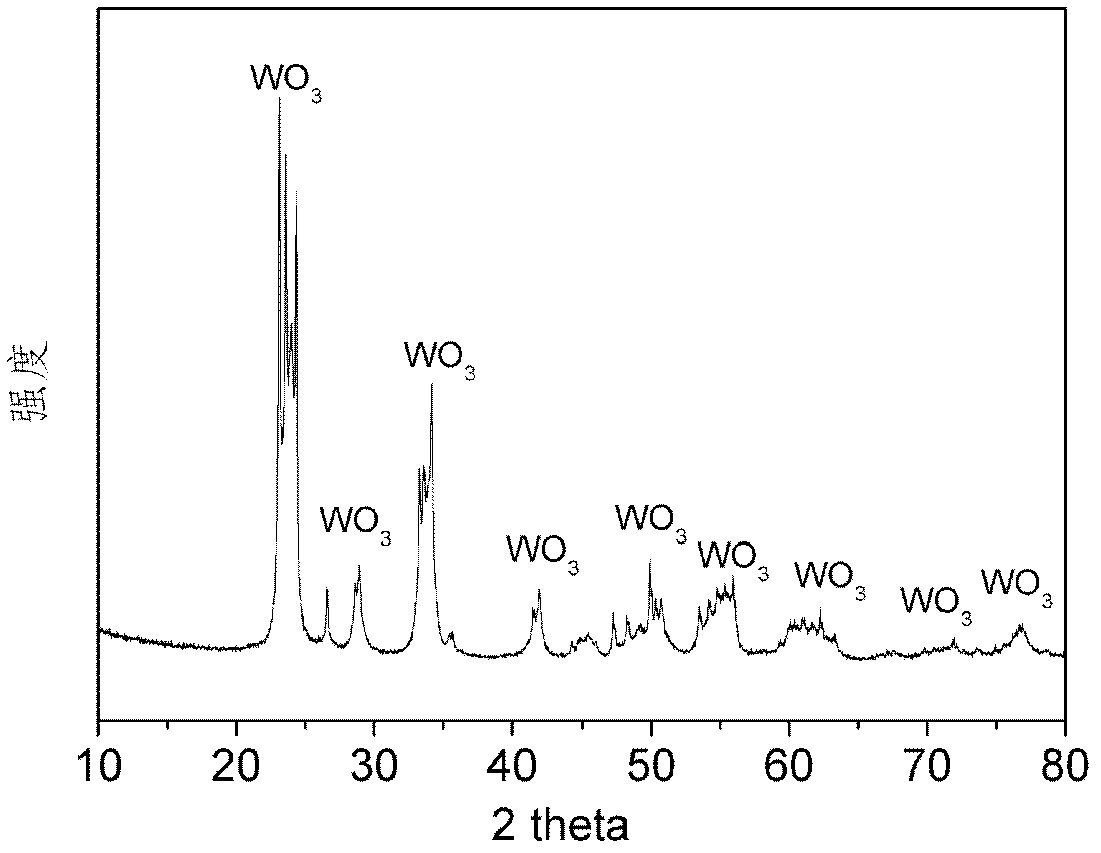

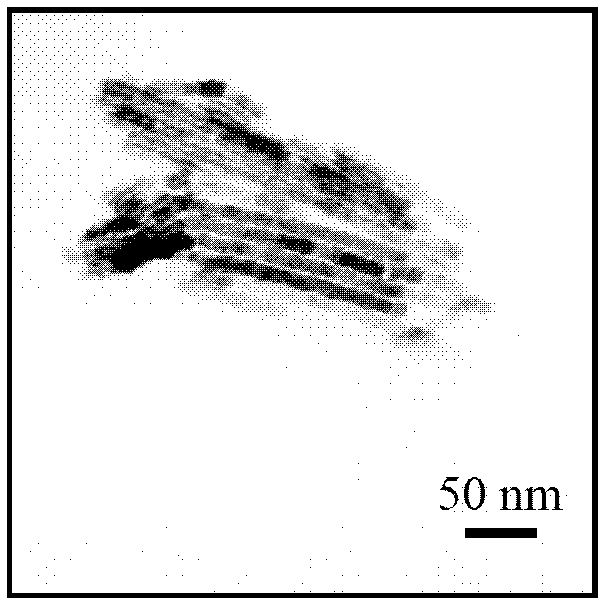

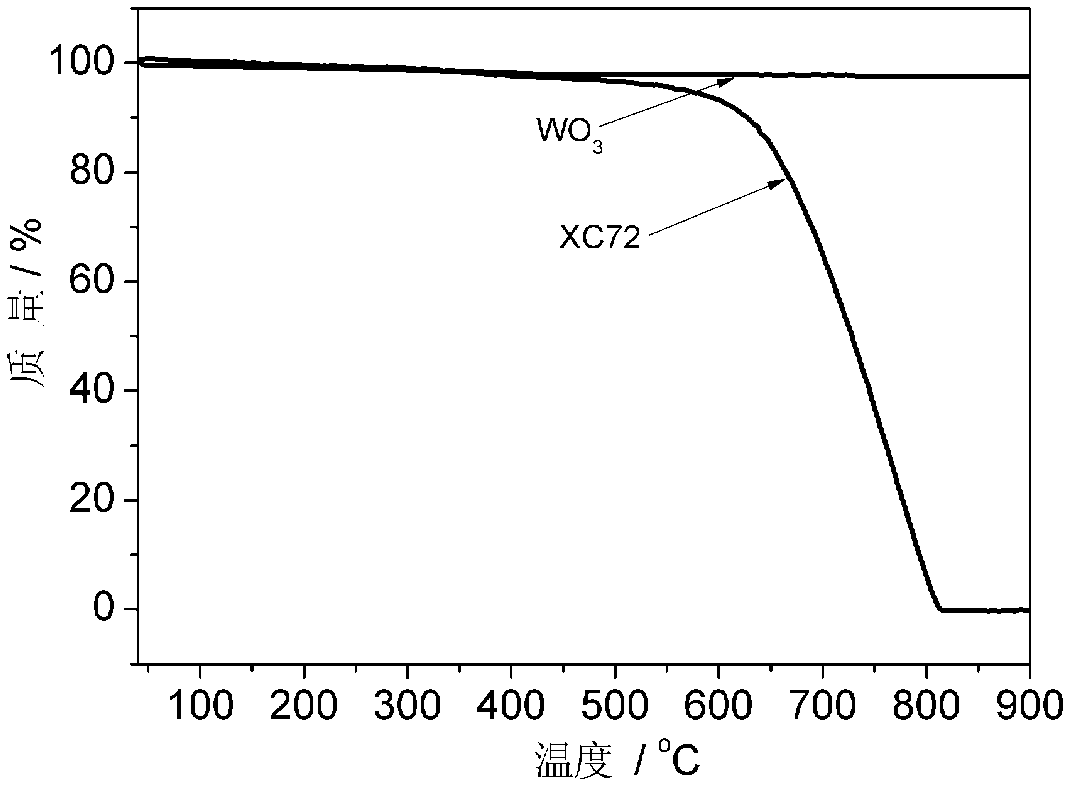

[0035] Preparation of Mesoporous Metal Oxide WO Using SBA-15 as Template 3 , the specific implementation method is: 1g SBA-15 is fully dispersed in 30mL ethanol solution, adding metal precursor silicotungstic acid, so that the molar ratio of silicon oxide to metal tungsten is 2, after fully stirring, slowly evaporate the solvent to dryness, and the obtained powder material Moved into a tube furnace, roasted in air at 600°C for 4h, with a programmed temperature rise rate of 2C min -1 . After cooling, remove the silica template with 15% HF, centrifuge, wash with deionized water for 4 to 6 times, and dry at 40°C for 12 hours to obtain the mesoporous metal oxide WO 3 . The prepared mesoporous metal oxide is highly crystalline monoclinic WO 3 (Such as figure 1 ), its specific surface area is 47m 2 g -1 , according to its TEM it can be seen that WO 3 It is a nanocluster composed of parallel nanorods, and the diameter of the nanorods is 7-9nm (such as figure 2 ), which has h...

Embodiment 2

[0037] Carry out experiment with the method identical with embodiment 1, difference with embodiment 1 is, make silicon oxide and metal tungsten molar ratio be 4, as Figure 5 As shown, the prepared mesoporous metal oxide WO 3 Due to the insufficient addition of tungsten precursor, the pores of the molecular sieve were not fully filled, and a relatively dispersed rod-like structure was formed, which shows that the addition of the precursor silicotungstic acid has a certain influence on the morphology of the prepared mesoporous metal oxide.

Embodiment 3

[0039] Experiment with the same method as Example 1, the difference from Example 1 is that the calcination temperature is 500 ° C, the prepared mesoporous metal oxide WO 3 Nano-replicated the pore structure of SBA-15

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com