A control method for restarting the motor after a high-voltage inverter loses power

A high-voltage frequency converter and control method technology, applied in the direction of motor generator/starter, single multi-phase induction motor starter, etc., can solve the problems of large measurement data, difficult industrial field application, complex calculation, etc., and achieve the physical concept Clear, less data collection, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A control method for electrical restarting of a high-voltage frequency converter after a power failure, characterized in that it comprises the following steps:

[0040] Step 1. When the motor is restarted after the inverter is powered off and restored, set the initial search frequency f of the inverter output 0 is the rated frequency f of the inverter N ,

[0041] Step 2. Set the output voltage of the inverter as u 0 , Among them, u N is the rated voltage of the motor;

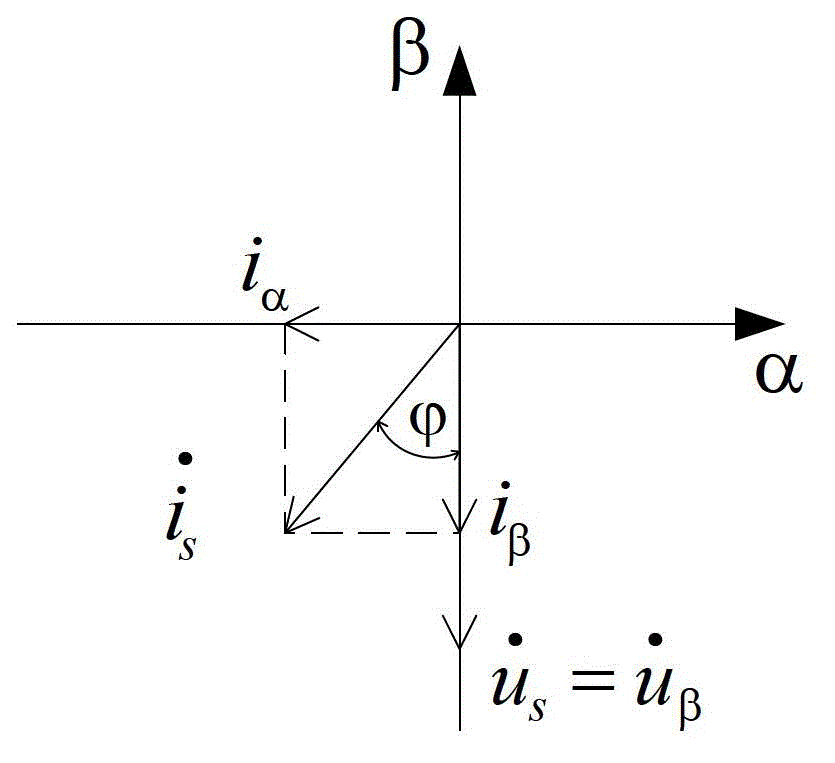

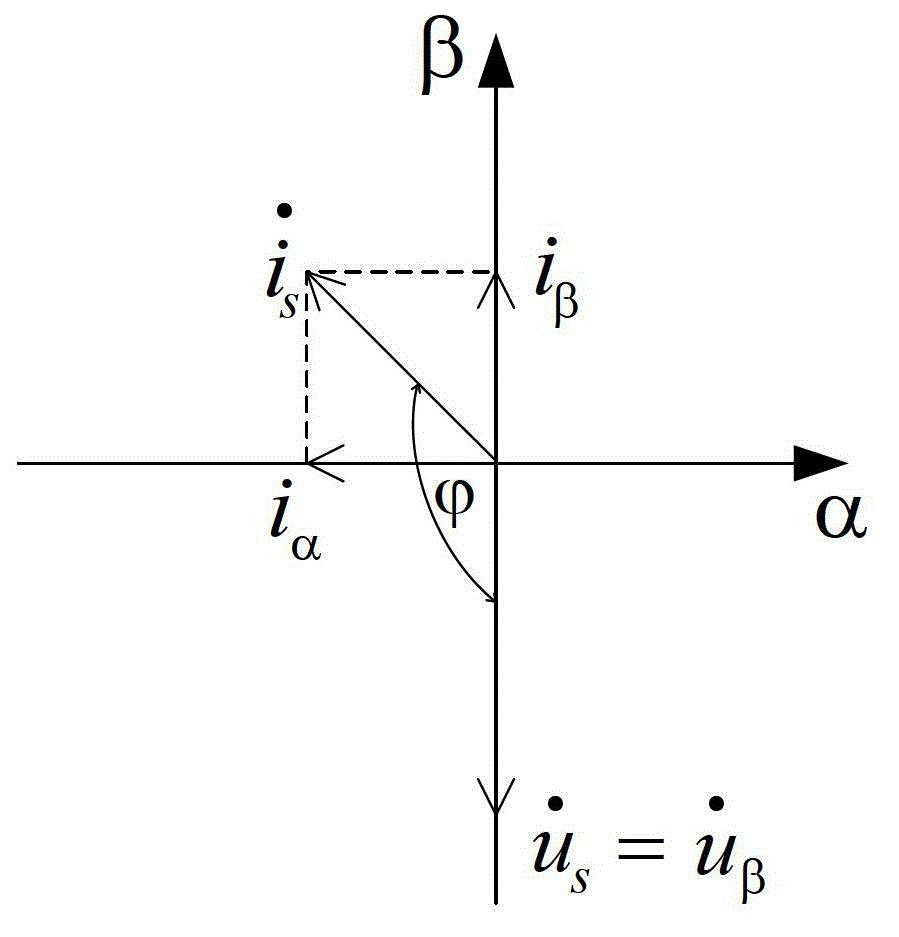

[0042] Step 3. Take the zero-crossing moment when the phase a voltage changes from negative to positive as the starting moment, and measure the three-phase voltages as u a , u b and u c ;Measure phase a current as i a , measure b-phase current as i b ;

[0043] u a = u m sin(ωt)

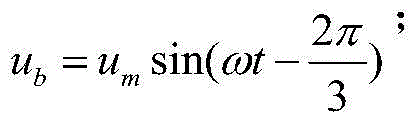

[0044] u b = u m sin ( ωt - 2 π...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com