Non-magnetic braking-force charged motor

A braking force and self-increasing technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of easy burnout of electromagnetic coils, high price, and unusable sparks, etc., and achieve good machining performance and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below in conjunction with the accompanying drawings:

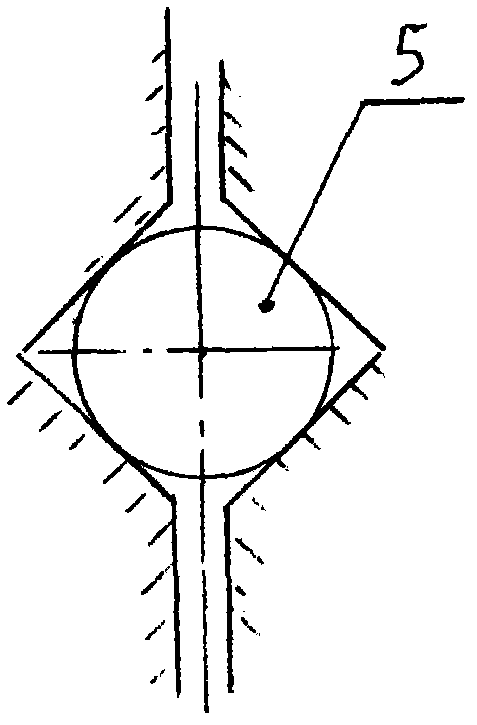

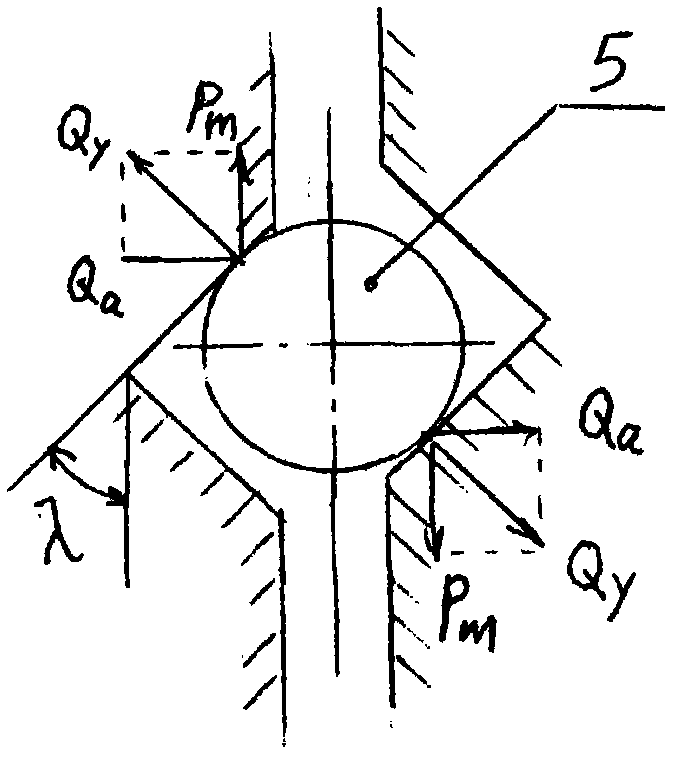

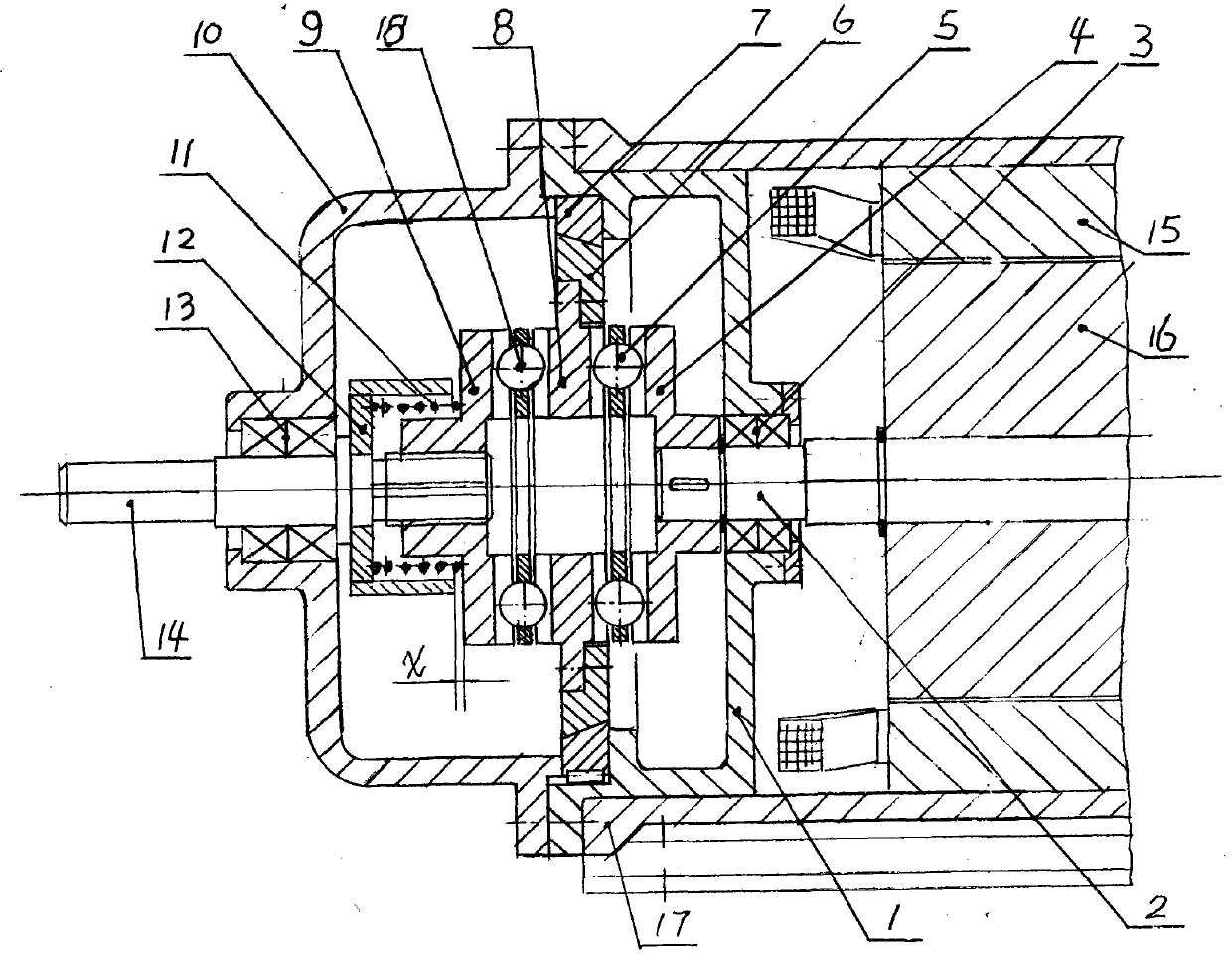

[0015] refer to figure 1 .2. and 3. A non-magnetic braking force self-increasing motor, including an embedded end cover (1), a rotor shaft (2), a rotor (16), a stator (15), a front end cover (10) and an output Shaft (14), the cylindrical part of the embedded end cover (1) is closely matched with the inner hole of the motor base (17), and the flange is connected to the end face of the base, and the bearing for the front end of the rotor shaft (2) (3) Supported in the inner hole of the embedded end cover (1), the output shaft (14) is supported in the inner hole of the front end cover (10) by a bearing (13), and the flange of the front end cover (10) is connected to the inner hole of the front end cover (10). The flange connection of the embedded end cover (1) is characterized in that: a double set of V-shaped groove di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com