Bunch stranding machine

A technology of stranding machine and transmission motor, which is applied in the manufacture of wire harnesses, electrical components, circuits, etc., can solve problems such as low work efficiency and complex structure of stranding machines, and achieve high production efficiency, simple structure, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

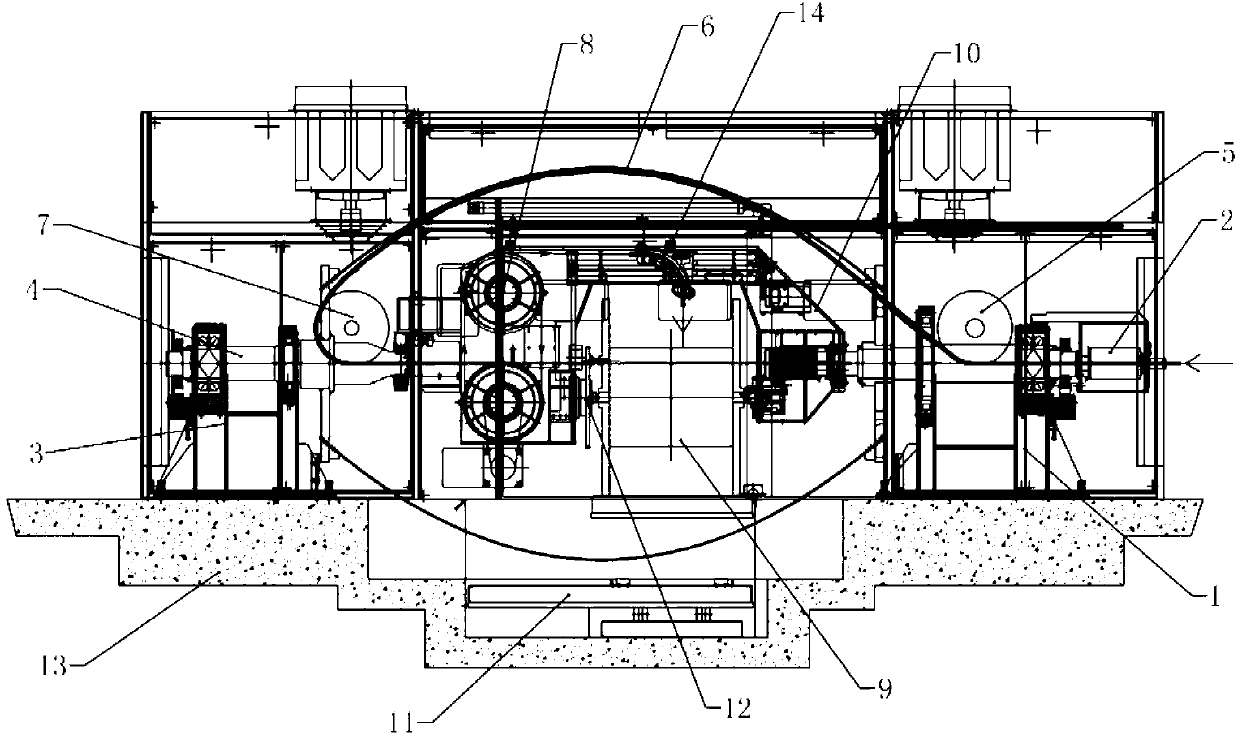

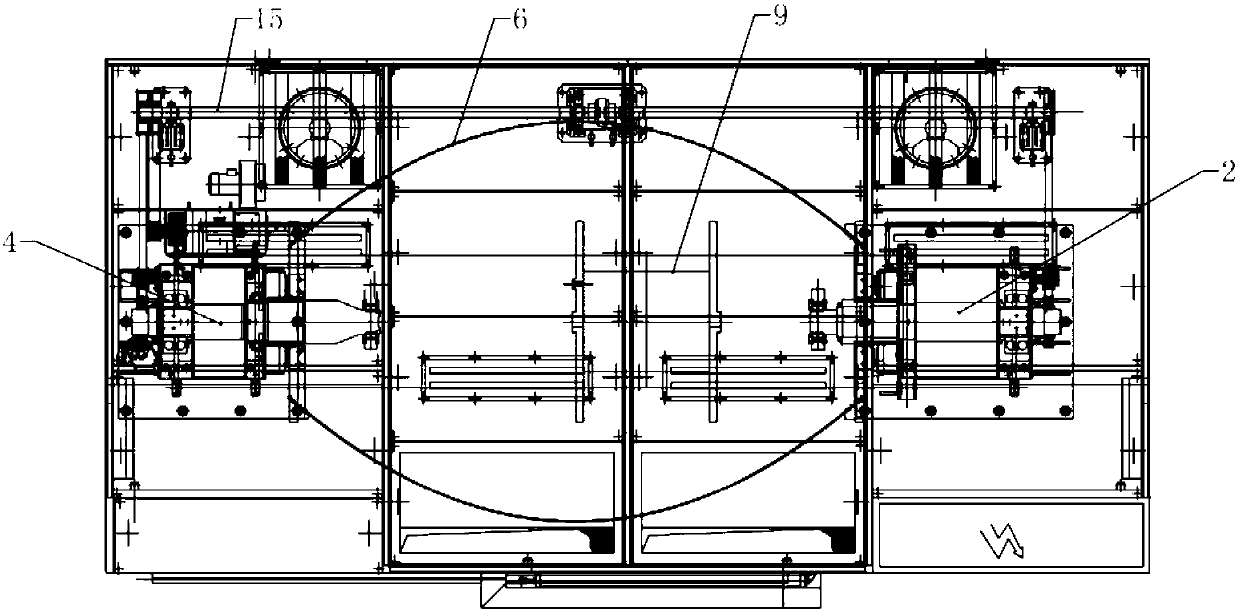

[0017] See figure 1 , the stranding machine of present embodiment comprises front and rear support 1,3 that is located on the base 13, front and rear support 1,3 bearings are respectively connected with coaxial line distribution and front rotating shaft 2, rear with central through hole. The shaft 4, the front shaft 2, and the rear shaft 4 are connected with a pair of bow straps 6 that bulge outwards and are symmetrically distributed. The pair of bow straps 6 are provided with bearings to connect between the front shaft 2 and the rear shaft 4. The cradle 10 of the pair of bow belts 6 is distributed with a plurality of lead wire guide wheels on the inner surface. The cradle 10 is provided with a winding reel 9 and a driving mechanism for driving the reel 9 to rotate, adjacent to the front The rear end of rotating shaft 2 and the front end of described rear rotating shaft 4 are respectively provided with front guide wheel 5, rear guide wheel 7, on described front rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com