Photovoltaic module flexible manufacturing control system based on field bus

A control system and photovoltaic module technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of inconsistent standards, failures, affecting production efficiency, etc., and achieve the effect of flexible network organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

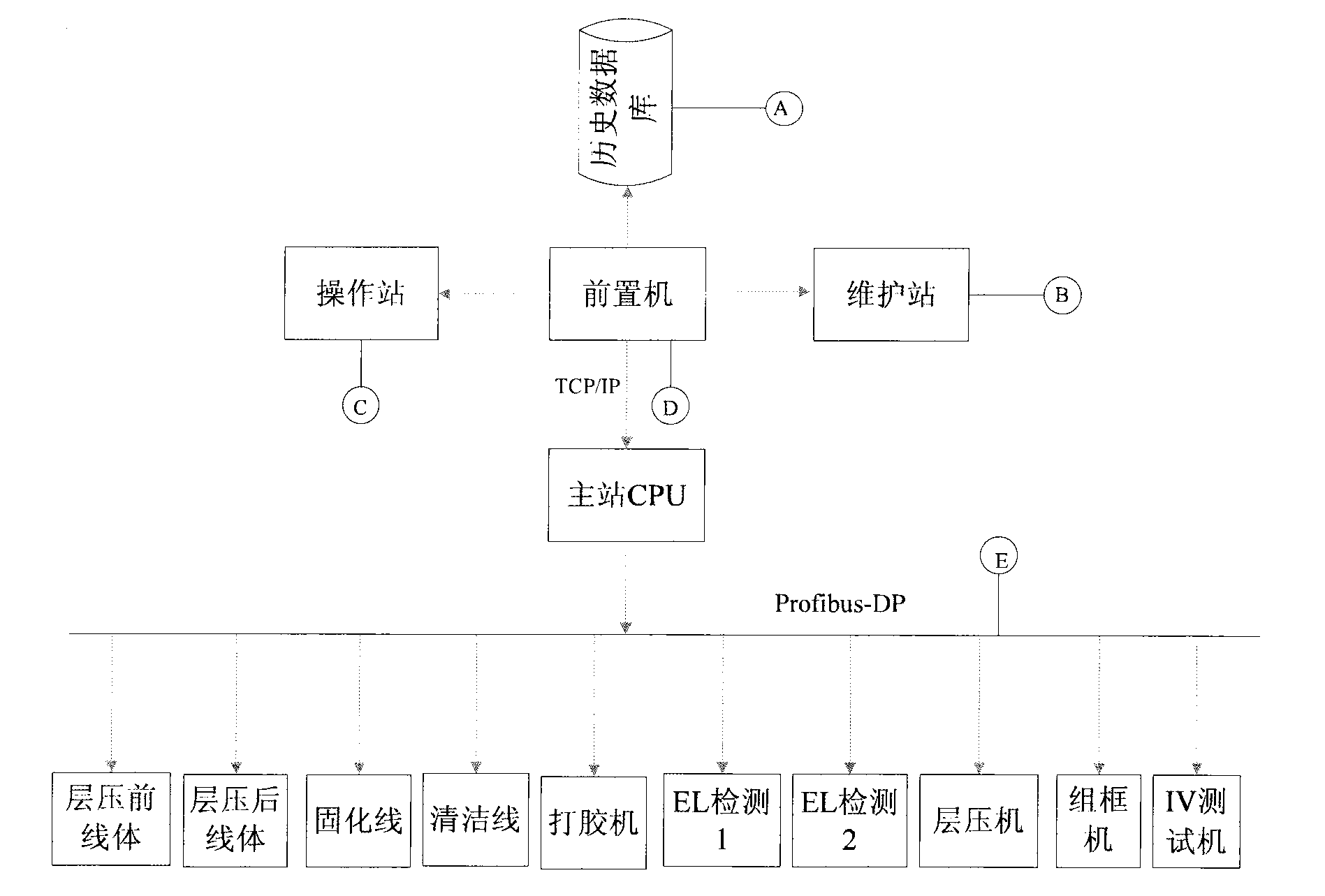

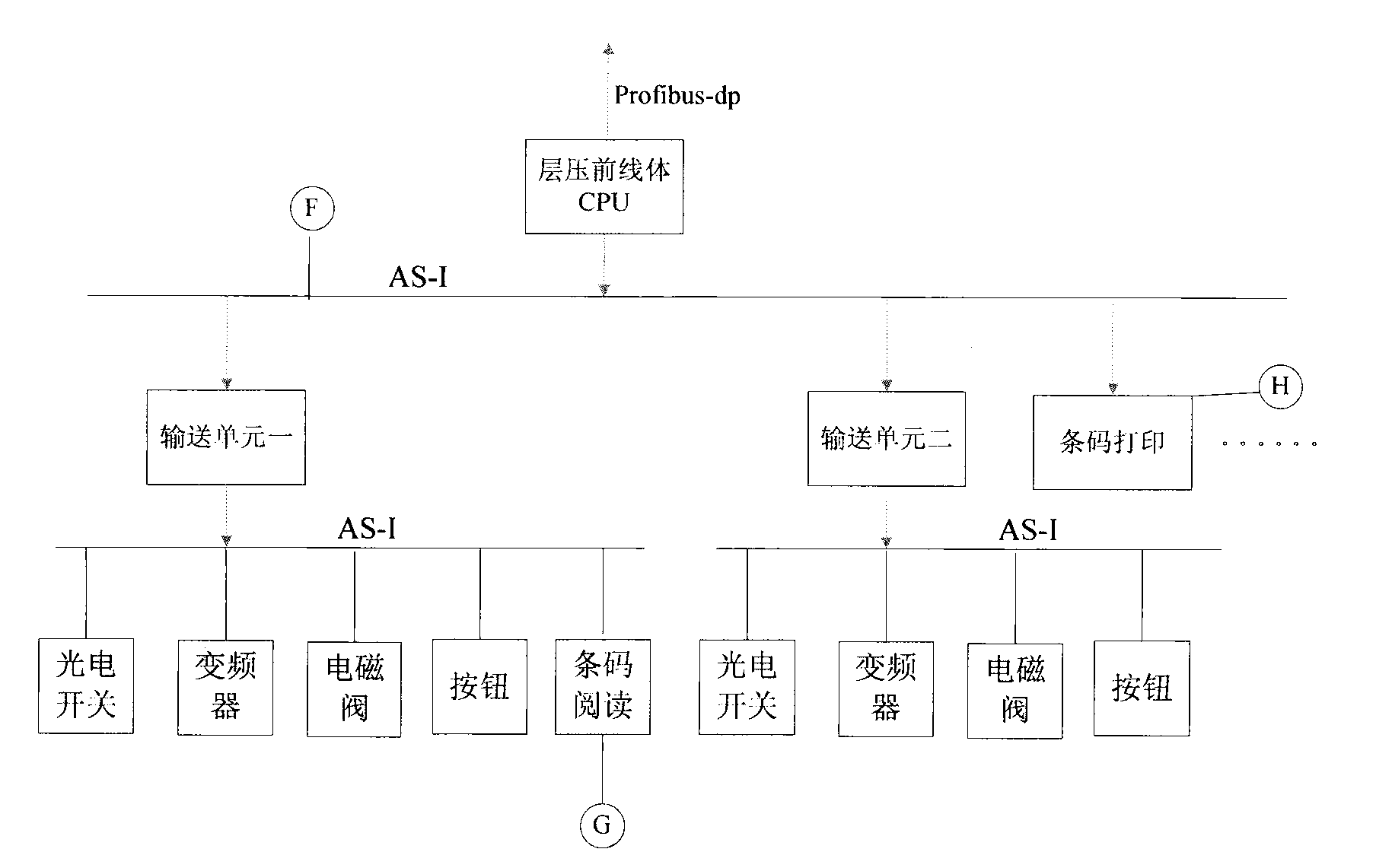

[0024] Such as figure 1 As shown, a fieldbus-based flexible manufacturing control system for photovoltaic modules includes an upper computer subsystem, a field master station, a line body control subsystem, and a special equipment subsystem, and each system is connected by Ethernet, Profibus, and ASI. This system integrates the application of Ethernet and field bus technology to improve the automation level of the production line.

[0025] Historical data is regularly written by the front-end processor, recording various production parameters in the component production process, including component after-sales feedback, etc. A complete informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com