Device for testing energy-saving water source heat pump performance coefficients

A test device and water source heat pump technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of large temperature fluctuations of cold and hot water, affecting test efficiency, wasting electric energy, etc., and achieve the reduction of circulating water volume Power consumption, time reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

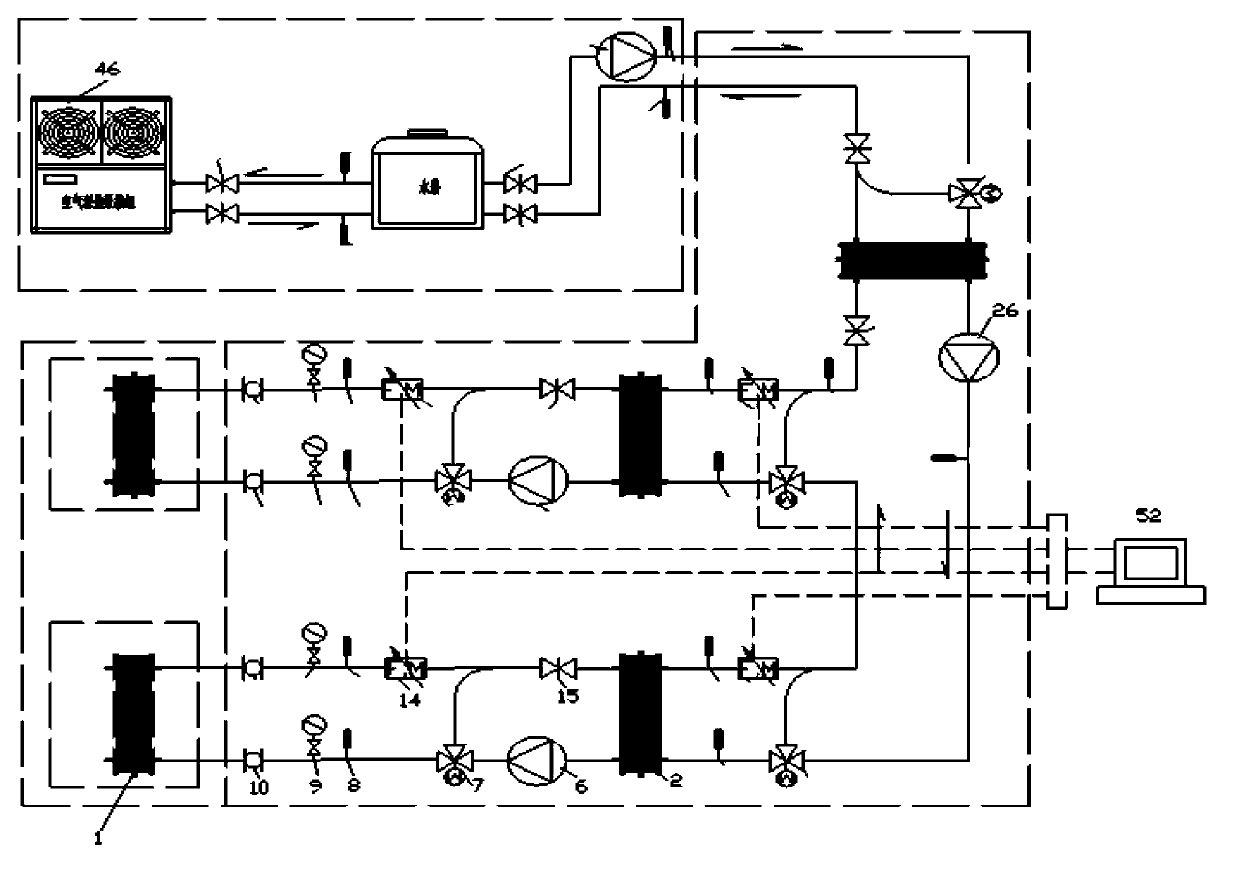

[0016] figure 2 Shown is an energy-saving water source heat pump performance coefficient test device, including the unit under test, cold water circulation circuit, hot water circulation circuit, mixed water circulation circuit and compensation circuit, the evaporator of the unit under test is connected to the cold water circulation circuit Connection, the condenser of the unit under test is connected to the hot water circulation loop through a soft connection; the mixed water circulation loop performs heat exchange with the cold water circulation loop and the hot water circulation loop respectively.

[0017] Among them, the cold water circulation circuit includes a cold plate changer 2, a water pump 6, a three-way solenoid valve 7, a thermometer 8 (with a temperature sensor, the same below), a pressure gauge 9, a soft connection 10, and a heat meter 14 (with a flow sensor, the same below) , Stop valve 15.

[0018] The hot water circulation circuit includes a hot plate excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com