A kind of preparation method of fusion protein inclusion body

A fusion protein and inclusion body technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of no biological activity, spatial conformation error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

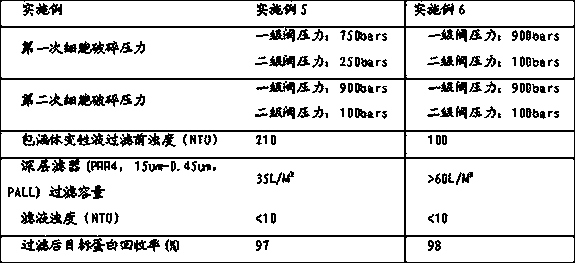

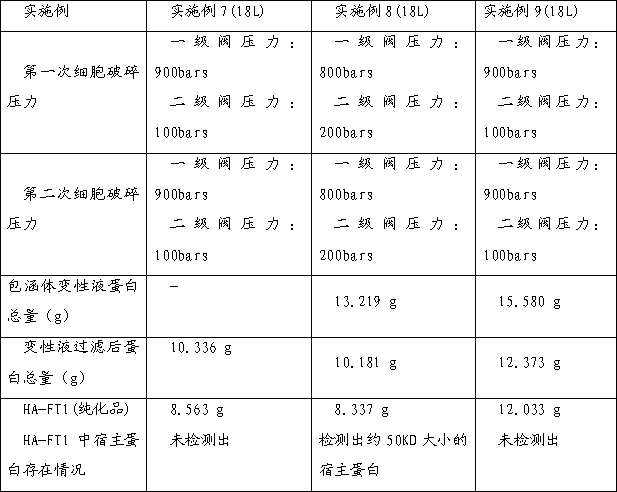

Examples

Embodiment 1

[0021] Bacteria reconstitution:

[0022] The Mtb72f engineered strain was inoculated into the fermentor to carry out high-density fermentation in a feed-through manner. When the fermentation broth OD650nm=50, IPTG was added for induction at 37°C, and the bacteria were harvested 5 hours after induction. Take a certain amount of bacteria (≥16L of bacteria during fermentation and harvest), add pre-cooled lysis buffer, and adjust the bacterial reconstitution to OD 650 nm≈60. Homogenize the bacterial compound solution with a high-speed homogenizer, and cool to ≤10°C after homogenization.

Embodiment 2

[0024] Broken bacteria:

[0025] The samples after cooling and homogenization are crushed by a high-pressure homogenizer. The pressure of the high-pressure homogenizer is adjusted to 100-150 bars for the second stage and 850-900 bars for the first stage, and the total crushing pressure is 1000±50 bars; The temperature should be controlled at ≤10℃, and the outlet sample temperature must be ≤25℃. The same batch of samples were crushed and processed twice, and the cell crushing liquid was obtained after the treatment.

Embodiment 3

[0027] Centrifugation and cleaning of broken bacteria liquid:

[0028] Add the same volume of lysis buffer to the bacterial cell crushing liquid, mix well and collect the inclusion bodies to settle with an industrial-scale centrifuge (such as a tubular high-speed centrifuge). The process temperature is less than 15°C. After centrifugation, the inclusion bodies are collected, and the inclusion body washing buffer is added to the equivalent volume when the cells are reconstituted, and then homogenized with high-speed homogenization (such as Ultra Turrax T50), and then the inclusion body precipitate is collected by a centrifuge. The process temperature is also less than 15°C. Repeat the cleaning and centrifugation steps for inclusion bodies. The inclusion bodies are collected, a small amount of washing buffer liquid is added, and high-speed homogenization is used to prepare an inclusion body suspension for purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com