Ferrous sulfate solution refrigerating crystallization device and method

A technology of ferrous sulfate solution and freeze crystallization, which is applied in the direction of solution crystallization, etc., can solve the problems that the temperature of the return water of the chilled water cannot be kept stable, the efficiency of the freeze crystallization device is reduced, and the service life of the freezer is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

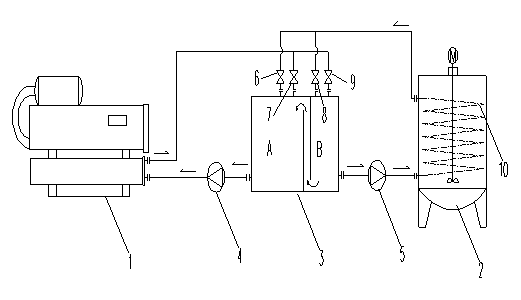

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0020] As shown in the figure, a ferrous sulfate solution frozen crystallization device includes a freezer 1, a frozen crystallizer 2 and a heat exchange tube 10 arranged in the frozen crystallizer, and also includes a cooling capacity adjustment tank 3, and the cooling capacity adjustment A baffle is arranged inside the tank, and the baffle divides the cooling capacity regulating tank into A region and B region which are partially communicated. The water inlet of the A region is connected with the chilled water outlet of the refrigerator through the first valve 7, so The water outlet of the A region is connected with the chilled water inlet of the refrigerator, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com