Electric screw press

A technology of electric screw and press, which is applied to the driving devices of presses, stamping machines, forging presses, etc. It can solve the problems of long slider length and small slider stroke, so as to increase forging energy and reduce contact Frictional resistance, the effect of accelerating the return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

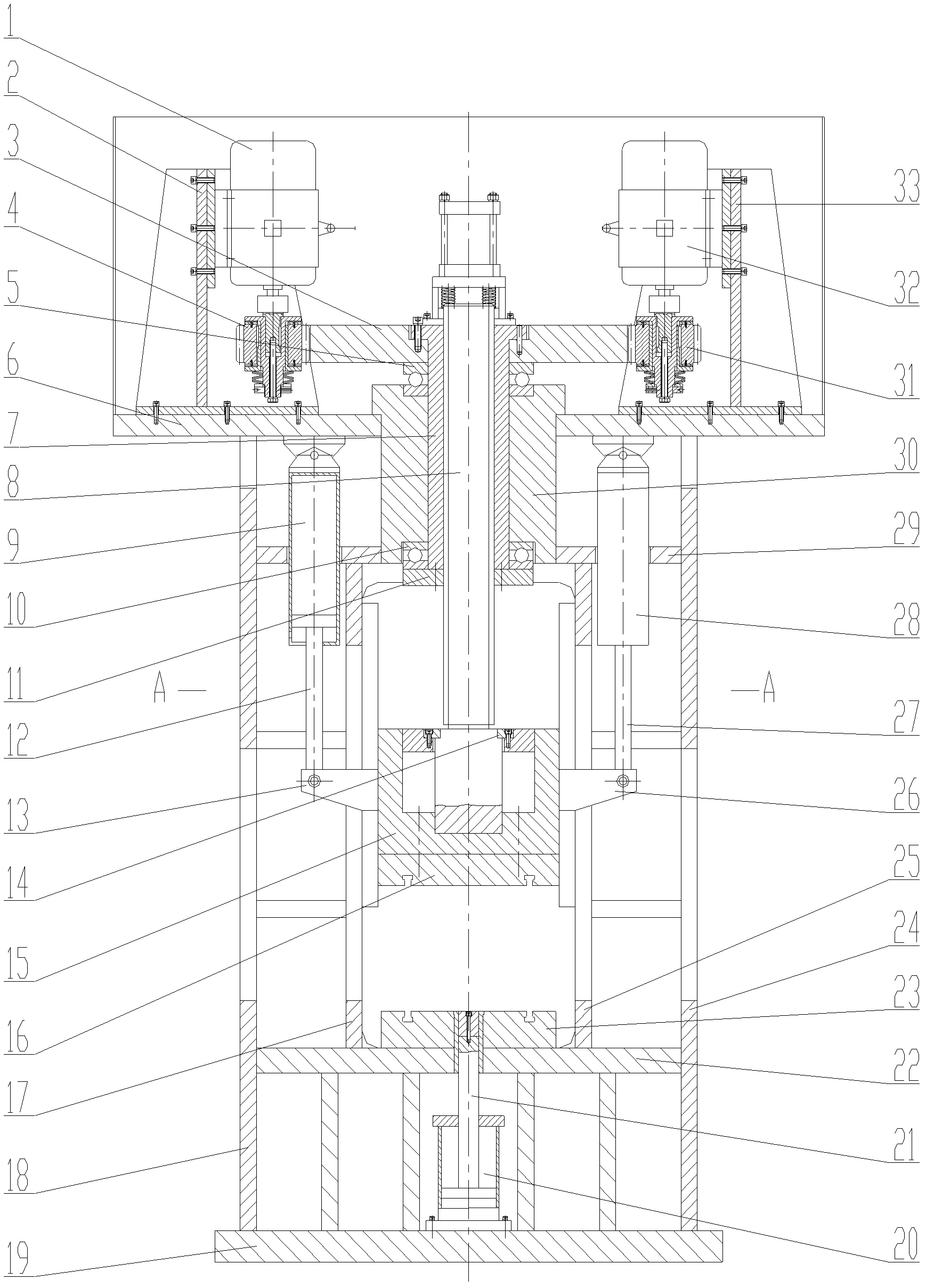

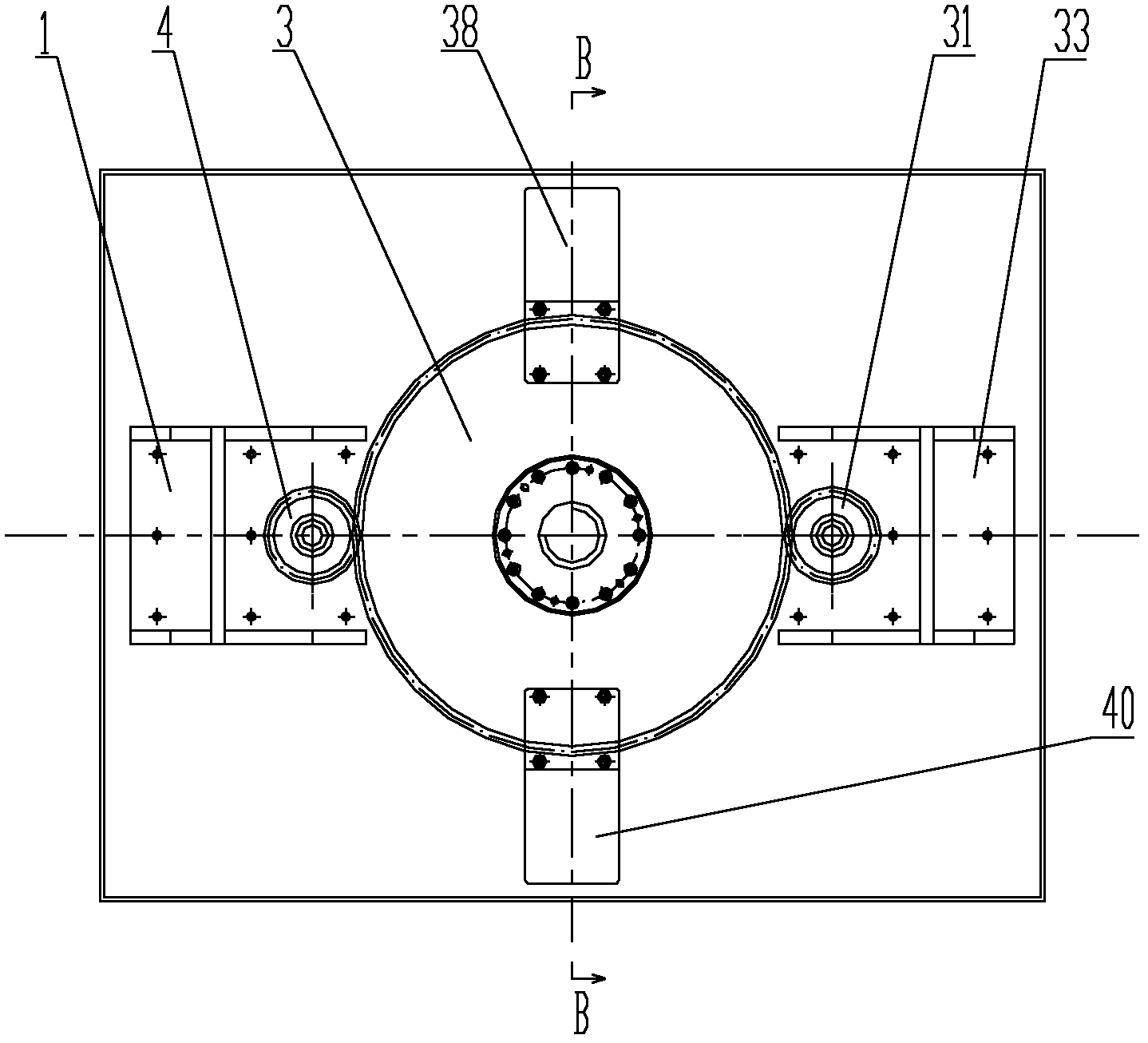

[0021] Such as Figure 1 ~ Figure 4 As shown, the embodiment of the present invention comprises upper beam top plate 6, left side plate 18, right side plate 24, lower beam bottom plate 19, bull gear 3, nut 7, screw rod 8, slider body 15, ejection cylinder 20, Left motor 1, right motor 32, front brake cylinder 38, rear brake cylinder 40;

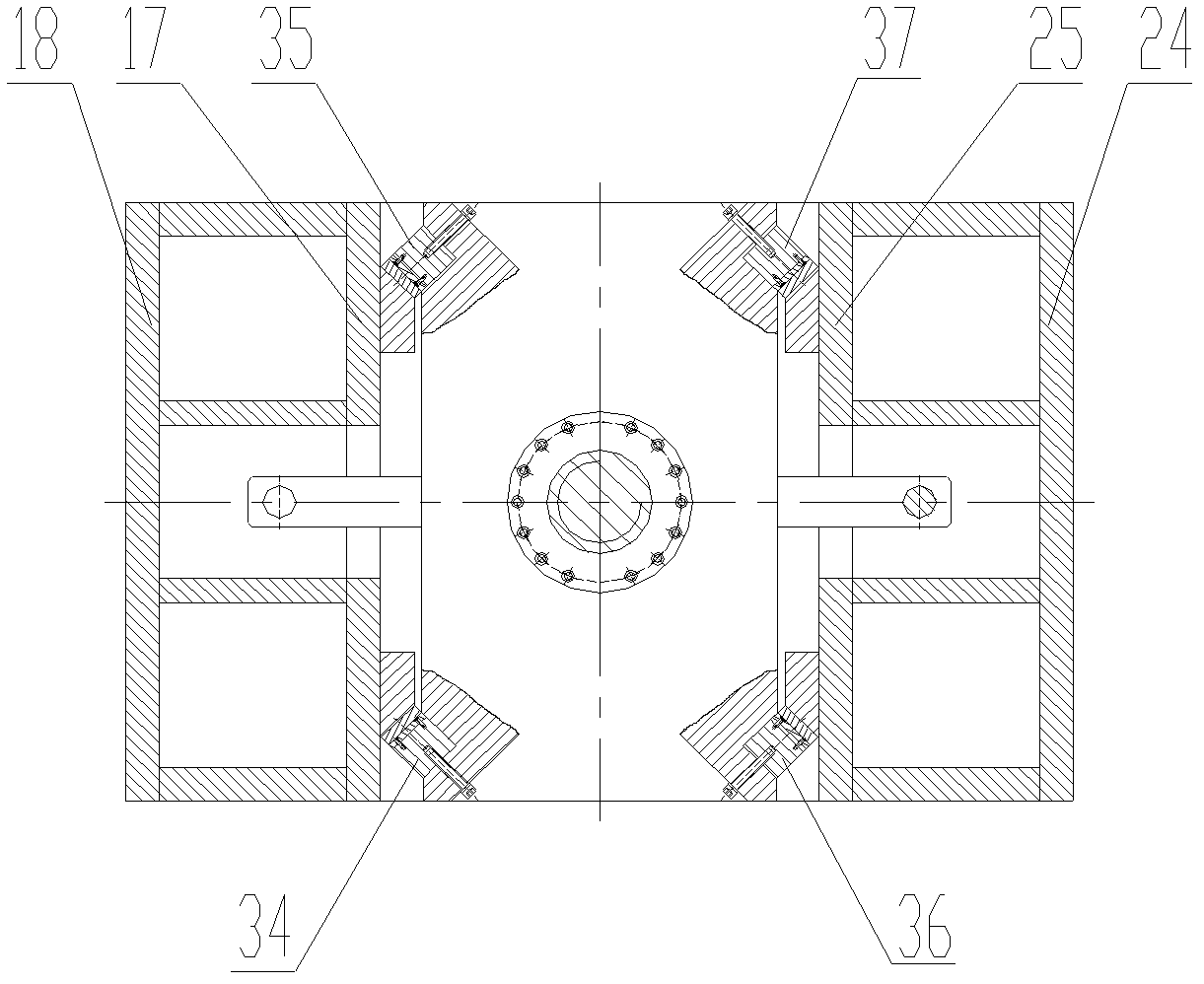

[0022] The fuselage is a frame structure, which is composed of an upper beam top plate 6, a left side plate 18, a right side plate 24, and a lower beam bottom plate 19. An upper plate 29 and a lower plate 22 are respectively fixed on the upper and lower parts of the fuselage. , the left inner panel 17 and the right inner panel 25 are fixed between the upper panel 29 and the lower panel 22, the left front guide rail 34 and the left rear guide rail 35 are fixed on the left inner panel 17, and the right front guide rail 36 and the right front guide rail 36 are fixed on the right inner panel 25. rear rail 37;

[0023] The central part of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com