Torch bracket

A bracket and welding gun technology, applied in the characteristics of welding rods, welding equipment, auxiliary welding equipment, etc., can solve the problems of shortening the life of welding gun cables, burning through high-temperature welding slag, and low space utilization, so as to improve the service life of welding guns, perfect Welding, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

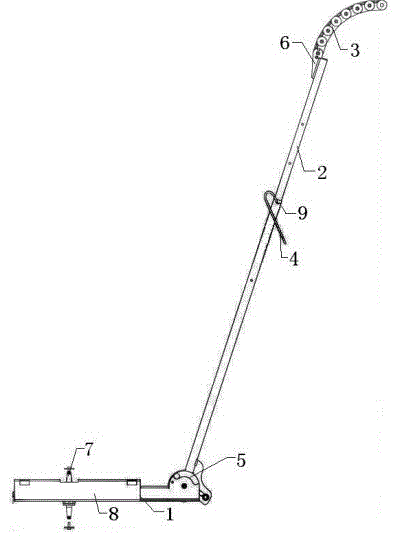

[0018] Such as figure 1 As shown, it is a welding torch bracket, including a bracket body 1, a support tube 2, a drag chain 3, a torch head fixing card 4, a movable flange 5, a support 6, the bottom end of the support tube 2 and the bracket body 1 is movably connected by a movable flange 5, and the top of the support tube 2 is provided with a drag chain 3 for supporting and fixing the welding torch cable; the support tube 2 and the hinge 3 are fixedly connected by a support 6. The support tube 2 is provided with a torch head fixing card 4 for placing the handle of the welding torch. The bracket body 1 is provided with a rotating shaft 7 matched with the welding machine for adjusting various angles of the welding machine in a horizontal position. The support tube 2 is a telescopic structure, and the bracket body 1 is provided with a cylinder 8 for realizing the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com