Precision manufacturing control system of distribution box sealing system

A sealing system and precision manufacturing technology, applied in coatings, devices for coating liquids on surfaces, etc., can solve the problems of low lifespan of sealing rings, low efficiency, and unguaranteed shape spraying volume, etc. Processing efficiency and precision, effect of uniform deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

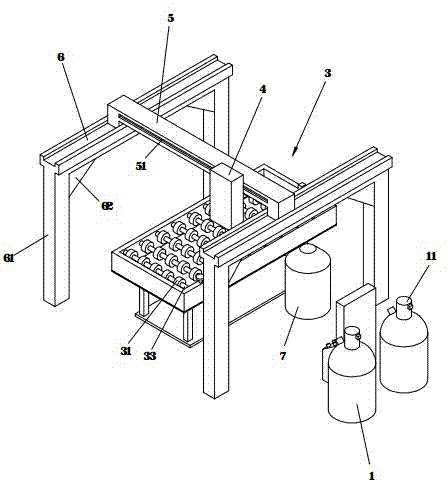

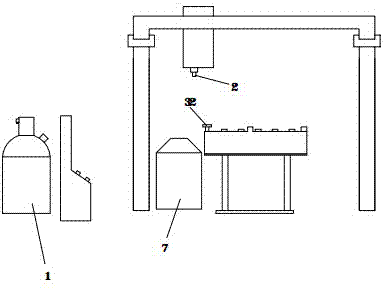

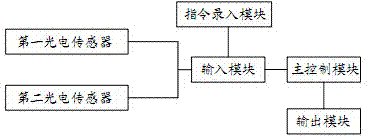

[0019] Such as Figures 1 to 3 As shown, a precision installation equipment for the sealing system of a distribution box includes a storage tank 1, a nozzle 2, a workbench 3 and a detection device. 4, the sliding block 4 is movably connected to the crossbeam 5, and the crossbeam 5 is movably connected to the guide rails 6 arranged on both sides of the workbench 3. The crossbeam 5 and the guide rails 6 are perpendicular to each other. The detection device includes two first A photoelectric sensor 81 and two second photoelectric sensors 82, the connection of the two first photoelectric sensors 81 is parallel to the beam 5, the connection of the two second photoelectric sensors 82 is parallel to the guide rail 6, Both the first photoelectric sensor 81 and the second photoelectric sensor 82 are connected to an input module, the input module is connected to a main control mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com