Automobile wheel hub aluminum alloy rim stroke machine

A technology for automobile wheels and aluminum alloys, which is applied to coatings and devices for coating liquid on the surface, etc. It can solve the problems of low stroke efficiency, uneven thickness, unstable center of gravity, etc., and improve the pass rate and production efficiency , stroke position is accurate, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

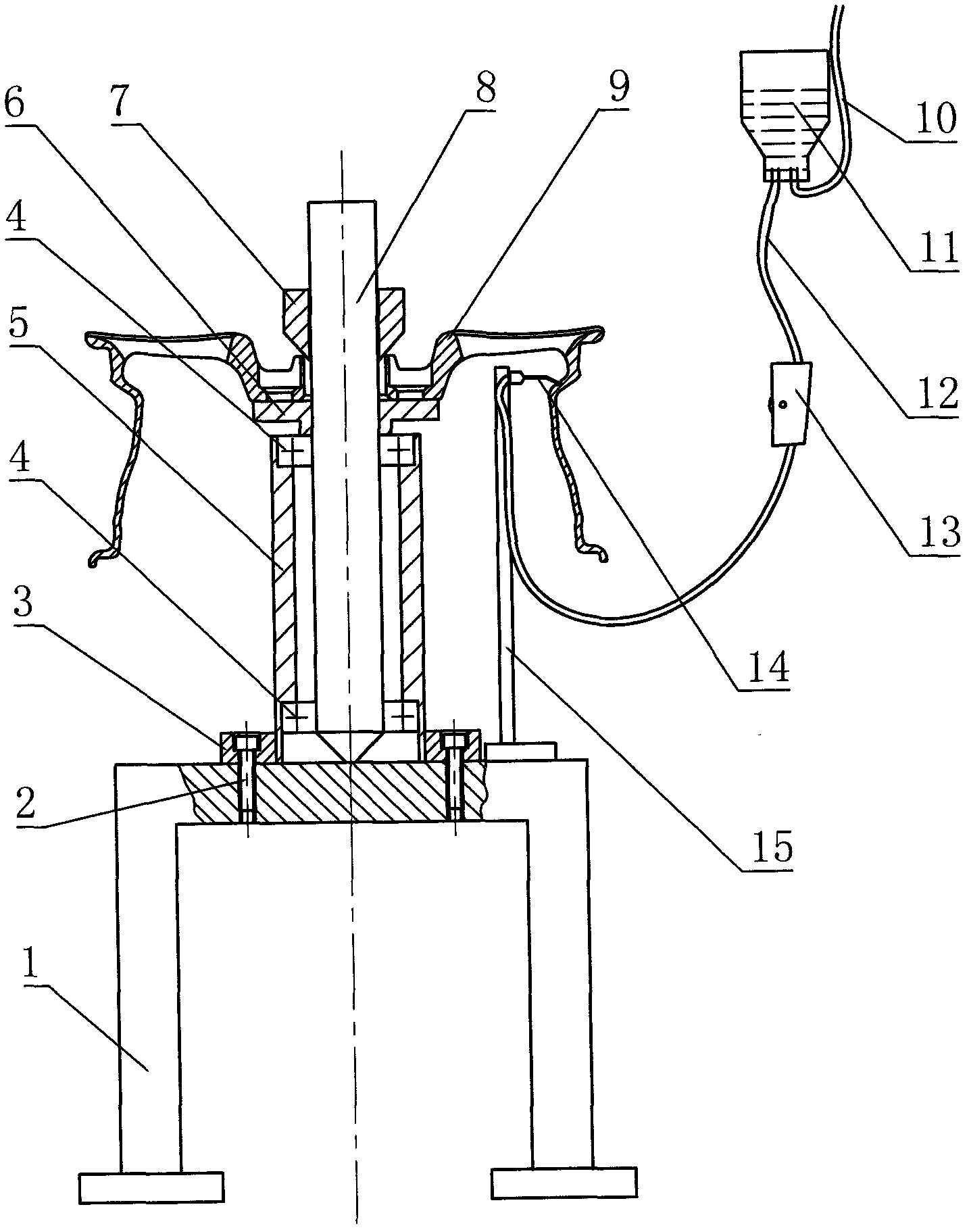

[0007] figure 1 Shown in is a specific embodiment of the present invention, the automobile wheel hub aluminum alloy rim stroke machine of the present invention comprises frame 1, connecting plate 3, cylinder 5, workbench 6, positioning cylinder 7, axle 8, through Air pipe 10, paint bottle 11, infusion tube 12, flow regulating valve 13, steel needle tube 14 and bracket 15, base plate 3 is fixed on frame 1 by screws 2, base plate 3 and cylinder 5 are connected together by welding, and the cylinder A bearing 4 is respectively housed in the inner holes at both ends, and the lower end surface of the workbench 6 is in contact with the bearing inner ring installed in the inner hole at the upper end of the cylinder 5 . A clearance fit is adopted between the inner hole of the positioning cylinder 7 and the outer circle of the shaft 8 . The lower end of the positioning cylinder 7 has an outer tapered surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com