Acupuncture needle and manufacture method thereof

A technology of acupuncture needles and needle handles, which is applied in the field of acupuncture needles, can solve the problems of crushed needle threads, unsafe use, and high production costs, and achieve the effects of avoiding mixed use, ensuring safe use, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

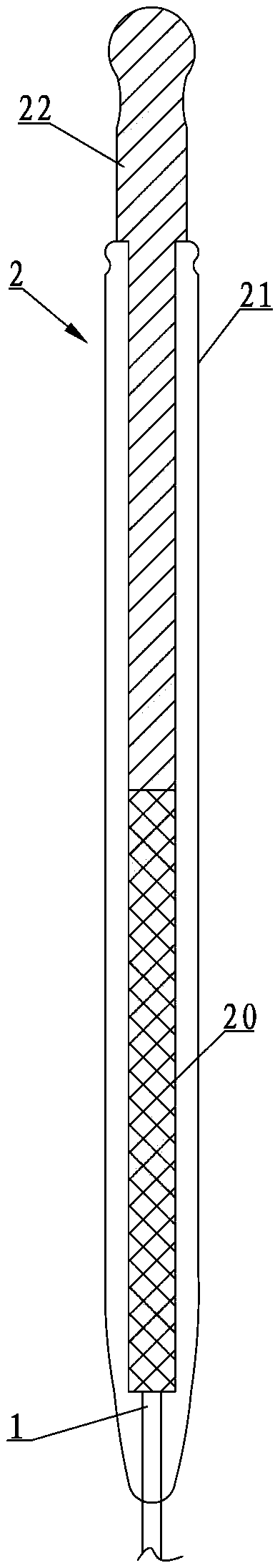

[0022] Such as figure 1 As shown, this example provides an acupuncture needle with a plastic handle, which includes a needle body 1 and a needle handle 2 . Wherein, the needle handle 2 further includes three parts: the needle body fixing tube 20, the needle handle frame 21 and the needle handle push rod 22. The material of the needle body fixing tube 20 is plastic or aluminum, the needle handle frame 21 and the needle handle push rod 22 are The material is plastic.

[0023] The needle handle frame 21 is a circular tube with an open upper end and a through hole at the lower end, and the needle handle frame 21 gradually narrows from the end where the opening is located toward the end where the through hole is located (from top to bottom), that is, the needle handle frame 21 The size of the cavity at the upper end is greater than the size of the cavity at the lower end of the needle handle skeleton 21 .

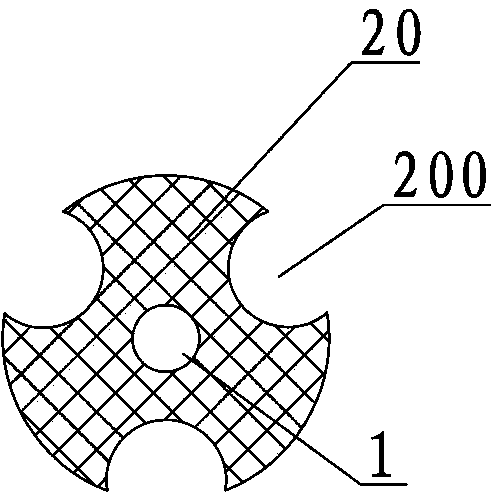

[0024] see figure 2 , the needle body fixing tube 20 can be in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com