Turkey leg pickling air-drying mature protein hydrolysis process regulation and control method

A technology of protein hydrolysis and turkey legs, which is applied in food preparation, application, food science, etc., can solve the problems of few types and restrict the scale development of turkey breeding industry, and achieve the goals of accelerating hydrolysis, improving flavor quality, and increasing lipase activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

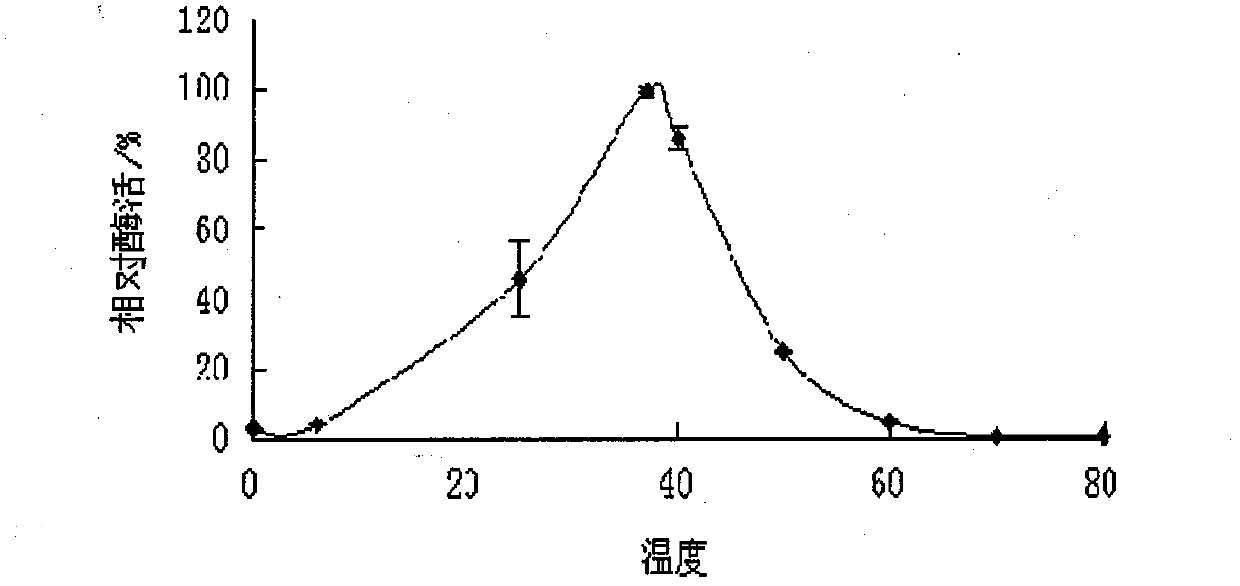

[0015] With frozen turkey lower leg as raw material (900 ± 150g), extract alanyl aminopeptidase (AAP), carry out the single factor experiment that temperature affects AAP activity, measure AAP activity under different reaction temperature conditions as attached figure 1 : AAP activity shows a trend of first increasing and then decreasing with the increase of temperature; a critical value is formed at 37.5°C, and AAP activity drops sharply after the temperature exceeds the critical value, so raising the temperature between 35°C and 40°C can be effective Improve and regulate the activity of AAP, accelerate the formation of protein hydrolysis and flavor quality of air-dried turkey leg products, and the high temperature will also inhibit the activity of AAP and the hydrolysis of protein and fat.

Embodiment 2

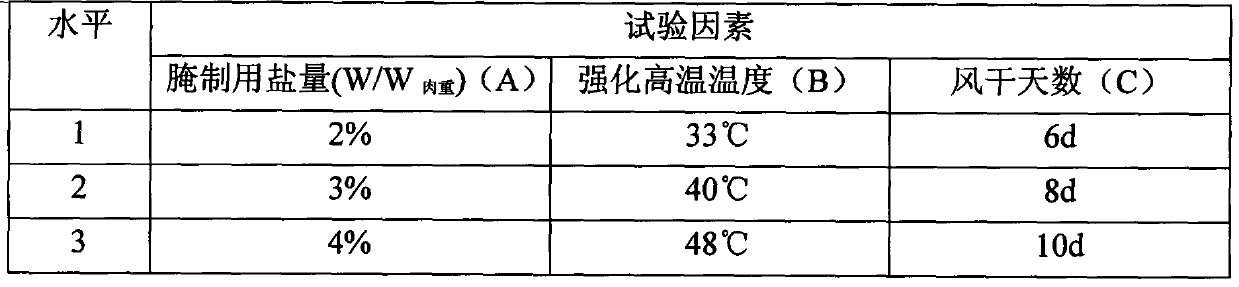

[0017] Thaw the frozen turkey leg (900±150g) naturally at 4°C, drain the surface water, pick turkey legs with uniform size and shape, and then conduct the orthogonal test according to Table 1.

[0018] Table 1 dry-cured turkey leg air-dried maturation process L9 (3 3 )Orthogonal design

[0019]

[0020] According to the experimental design in Table 1, first spread half of the amount of salt used for curing on the surface of the turkey leg, marinate at 6°C and 80% RH for 4 hours, then apply the remaining salt and marinate for 3 days; the curing is over Placed in a temperature-controlled and humidity-controlled environment, strengthen the high temperature for 120 minutes at a temperature of 33°C-48°C and a humidity of 80% RH, and then gradually air-dry and mature according to the initial temperature of 18°C and the heating program of 1°C / 24 hours. Humidity is controlled within the range of 68%-76% RH and drops gradually, with a daily drop of 0.5%.

[0021] Experimental r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com