Graft polymer to which combined nitrogen molecules are grafted

A technology for polymers and compounds, applied in organic chemistry and other directions, can solve problems such as reducing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

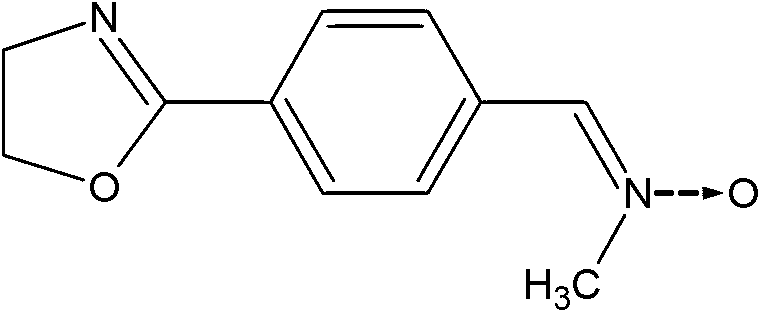

[0105] Example 1: By grafting 2,4,6-trimethyl-3-(2-(2-oxyimidazolidin-1-yl)ethoxy) Nitrile Oxide Modified SBR

[0106] 1.1- Preparation of Modifier:

[0107] a) Preparation of 1-(2-(3'-nitrileoxytrimethylphenyl-1'-oxyl)ethyl)imidazolidin-2-one

[0108]

[0109] This compound can be prepared from hydroxyethylimidazolidinone tricresylphenol according to the following synthetic scheme.

[0110]

[0111] b) Preparation of 3-hydroxy-2,4,6-trimethylbenzaldehyde

[0112]

[0113] This compound can be obtained according to the procedures described in the following articles: Yakubov, A.P.; Tsyganov, D.V.; Belen'kii, L.I.; Krayushkin, M.M.; Bulletin of the Academy of Sciences of the USSR, Division of Chemical Science (English Translation) ; vol.40; nb.7.2; (1991); pp. 1427-1432; Izvestiya Akademii Nauk SSSR, Seriya Khimicheskaya; nb.7;

[0114] c) Preparation of 1-(2-chloroethyl)imidazolidin-2-one:

[0115]

[0116] This product is described in the article Naga...

Embodiment 2

[0174] Example 2: By grafting 2,4,6-trimethyl-3-(2-(2-oxoimidazolidin-1-yl)ethoxy) Bulk Modified Polyisoprene

[0175] 2.1- Modifier grafted to polyisoprene Natsyn2200 (Goodyear)

[0176] The same modifier as that obtained in Example 1 before was used.

[0177] 2.85 g of 2,4,6-trimethyl-3-(2-(2-oxoimidazolidin-1-yl ) ethoxy) nitrile oxide doped with 30 g of polyisoprene Natsyn 2200 ([ML(1+4) 100°C=79, unit 3,4=0.5%, unit trans 1,4=1.9%, unit cis 1,4=97.6%, Mw=1044.10 3 g / mol, Vp=3.6]). The mixture was homogenized 15 times.

[0178] This mixing stage was followed by a heat treatment in a press at a pressure of 10 bar.

[0179] The duration and temperature of this second phase are adjusted.

[0180] 1 H NMR analysis made it possible to determine the molar amount of grafting and the molar yield of grafting, which are reported in the table below:

[0181] Table 6

[0182]

[0183]

Embodiment 3

[0184] Example 3: By grafting 3-methoxy-4-[2-(2-oxyimidazolidin-1-yl)ethoxy]benzyl Nitrile Oxide Modified SBR

[0185] 1.1- Preparation of Modifier:

[0186] a) Preparation of 3-methoxy-4-[2-(2-oxyimidazolidin-1-yl)ethoxy]benzonitrile oxide

[0187]

[0188] This compound can be prepared from vanillin and 2-chloroethyl imidazolidinone according to the following synthetic scheme:

[0189]

[0190] b) Preparation of 3-methoxy-4-[2-(2-oxyimidazolidin-1-yl)ethoxy]benzaldehyde

[0191]

[0192] Route A

[0193] Vanillin (30.0g, 0.197mol) and K 2 CO 3 (95.4 g, 0.690 mol) in DMF (200 mL) was heated at 50°С for 15 min. To this suspension was added 1-(2-chloroethyl)imidazolidinone-2-one (44.0 g, 0.296 mol, purity >90%) in DMF (30 mL), 1-(2-chloroethyl The preparation of the imidazolidinone-2-one has been described in Example 1. The reaction medium is heated to 90°C (T 浴 ), the temperature is maintained for about 4 hours. The reaction medium was allowed to come...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com