Cover plate structure

A cover plate and plate technology, which is applied in the field of cover plate structure, can solve the problems of user trouble, lack of gripping force, interruption of electrical connection of the connector 20, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical means and functions used by the present invention to achieve the purpose will be described below with reference to the attached drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, so as to facilitate the examiner's understanding, but the technical means of the present invention It is not limited to the figures listed.

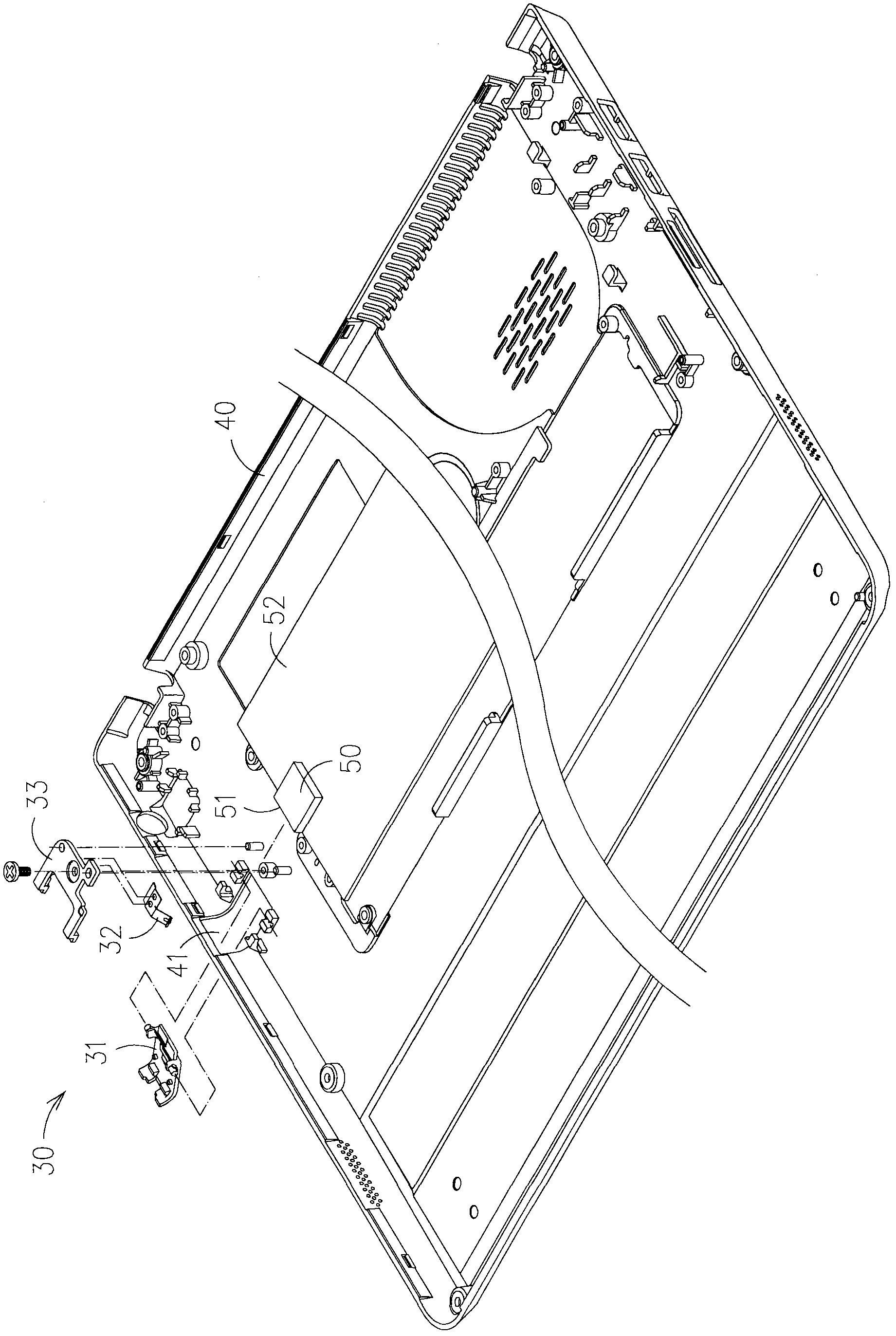

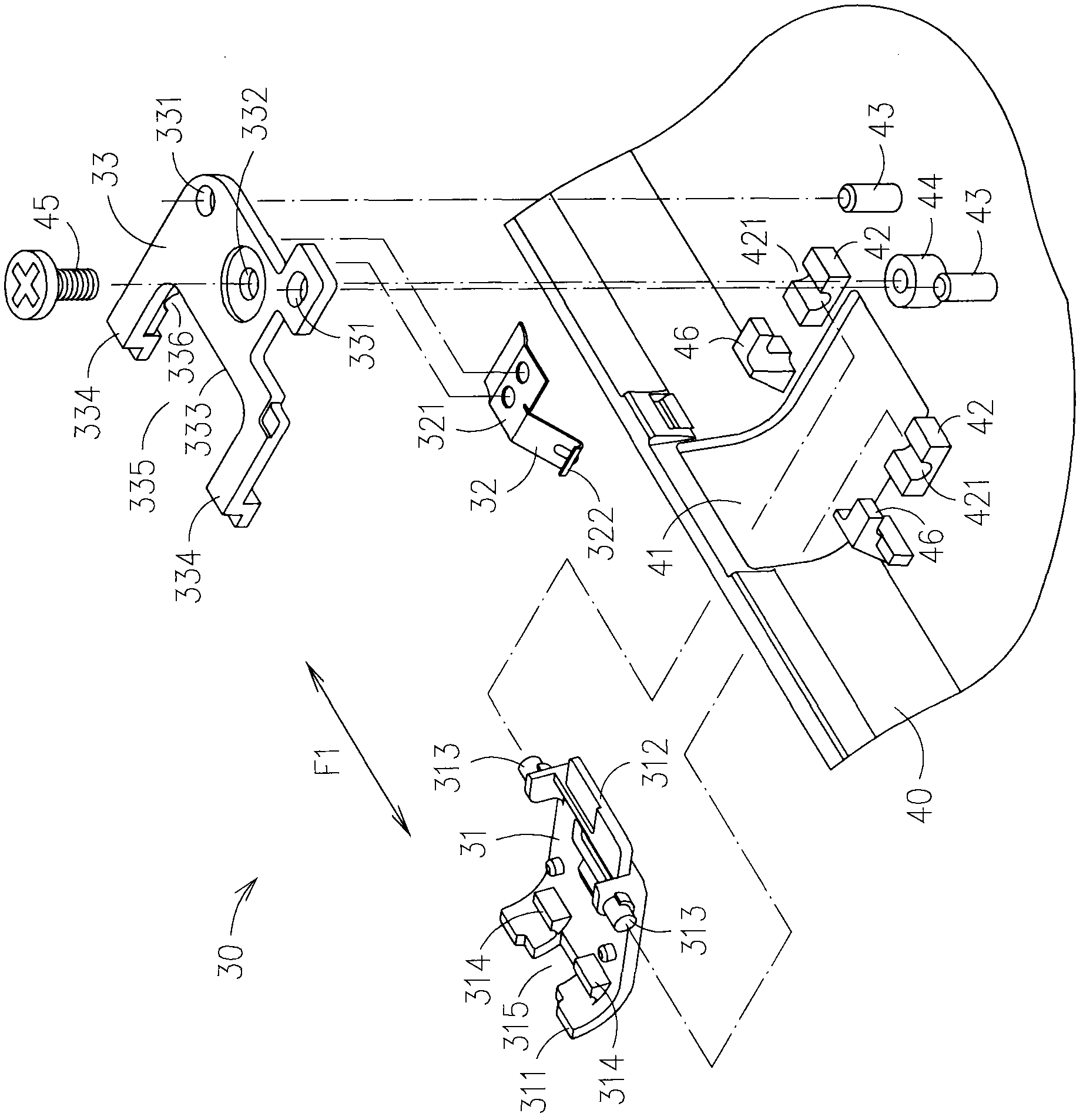

[0030] see Figure 2 to Figure 4 As shown, the cover plate structure 30 provided by the present invention is arranged on a casing 40, an opening 41 is provided in the casing 40, a connecting seat 50 is arranged in the casing 40, and the connecting seat 50 is arranged on a circuit board 52 Above, the connecting base 50 has a plugging end portion 51 , the plugging end portion 51 is embedded in the opening portion 41 from the housing 40 and exposed to the opening portion 41 . The opening 41 can provide a connector (not shown in the figure) to be inserted into the housing 40 from the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com