A light guide, object containing the light guide, and manufacturing and assembling methods thereof

A manufacturing method and technology of light guides, applied in the direction of optical waveguide light guides, optical elements, coupling of optical waveguides, etc., capable of solving problems such as difficulty in assembly of light guides, misalignment of light guides, and misalignment of light guides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

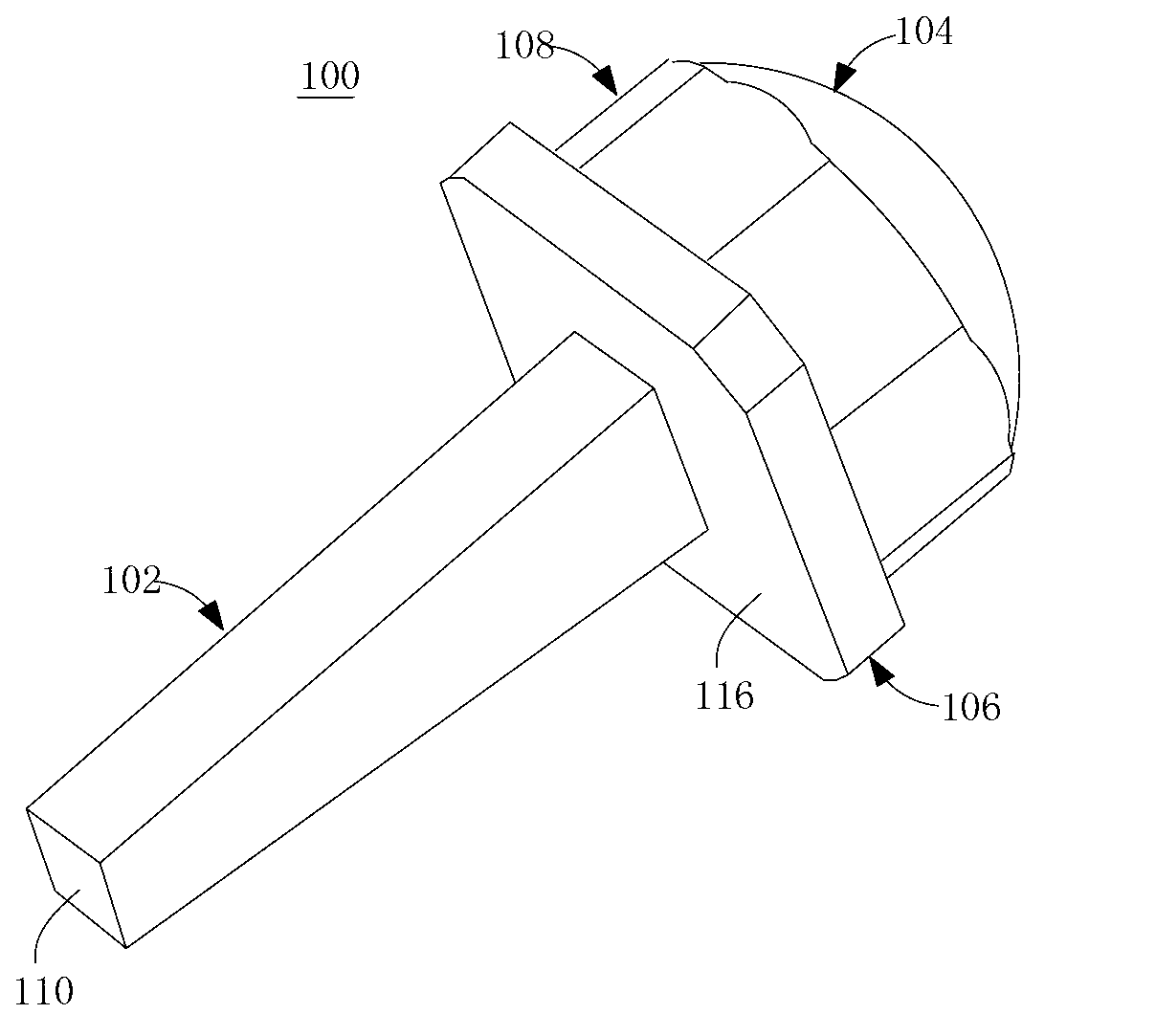

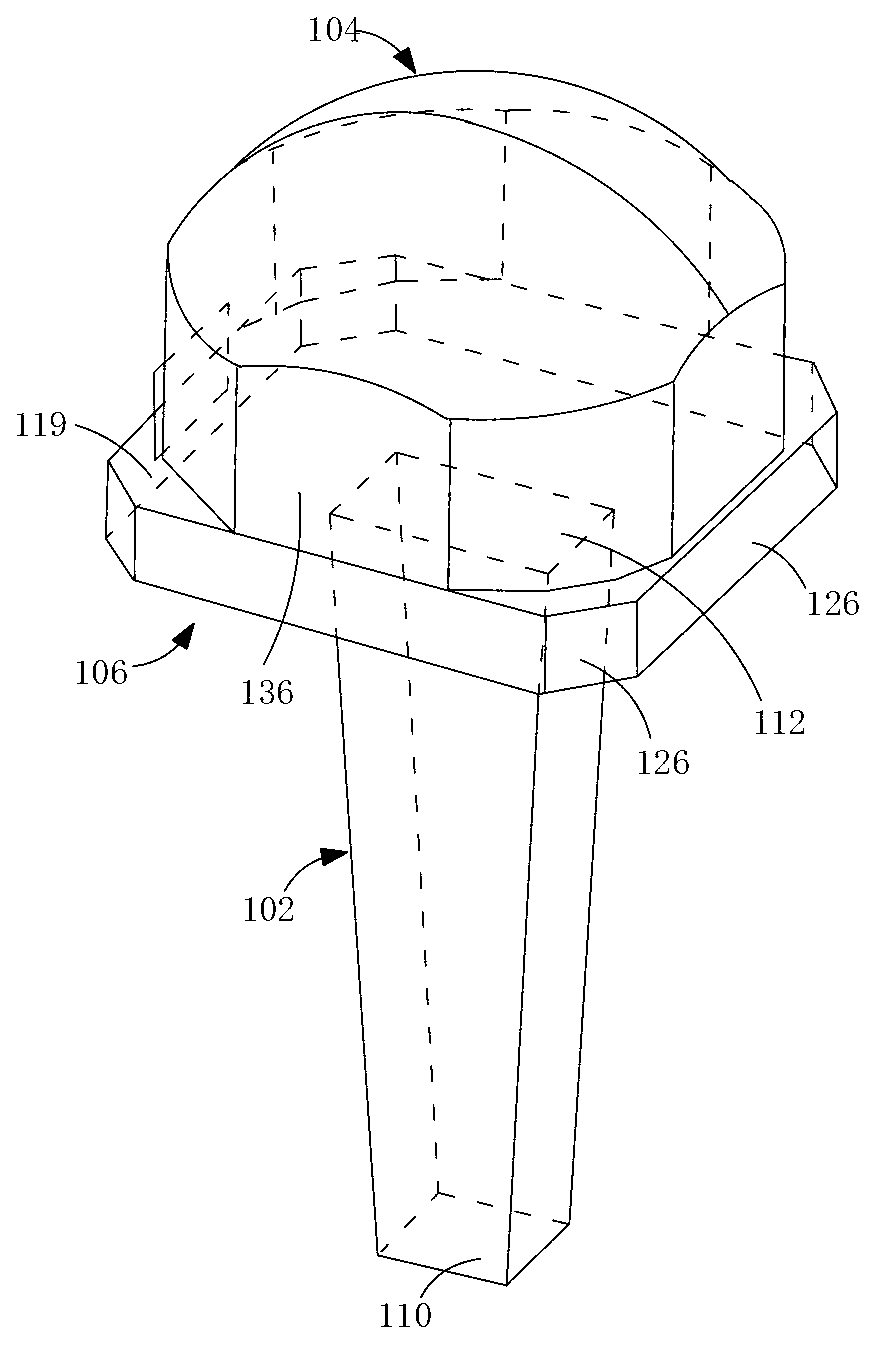

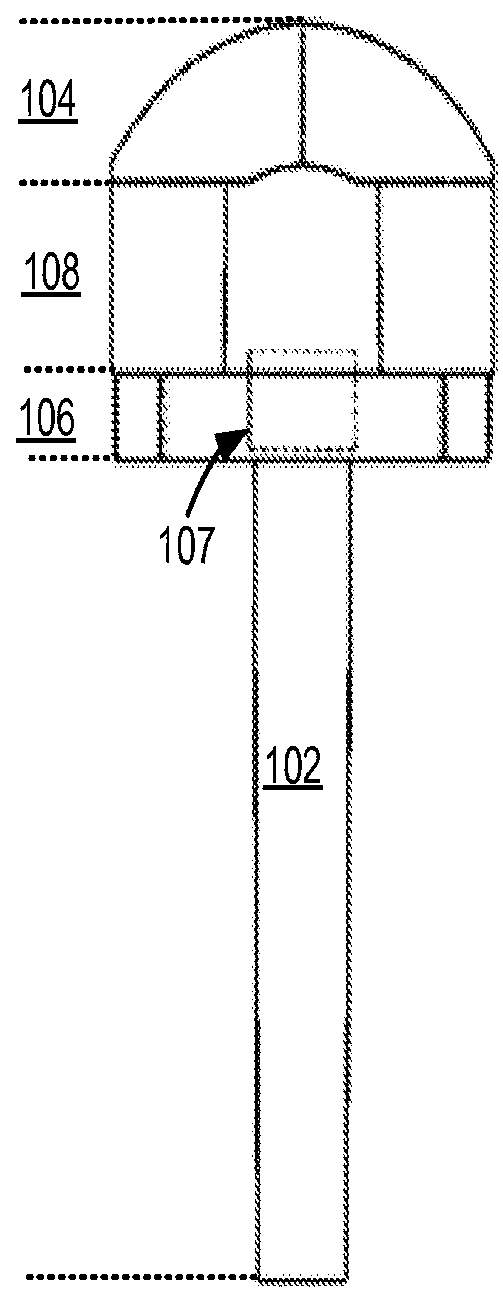

[0048] The light guide, the light engine including the light guide, the light source kit including the light guide, the manufacturing method of the light guide and the assembly method of the light source kit are disclosed below.

[0049] A one-piece light guide and a method of manufacturing the same are disclosed below. A one-piece light guide member according to an embodiment of the present invention includes a light collecting rod and a lens. In an embodiment of the present invention, the light collecting rod can integrate light with different colors. In one embodiment of the invention, the lens is a collimating lens. In an embodiment of the invention, the one-piece light guide is formed by injection molding and the one-piece light guide is inexpensive to manufacture. In addition, the one-piece light guide eliminates the need to adjust the lens to the collecting column. Be aware that some traditional light guides still need to align the lens with the light collecting colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com