Method for connecting single-layer collar knitted by flat knitting machine with single-layer garment body knitted by flat knitting machine

A flat knitting machine and single-layer technology, applied in the field of knitting machinery, can solve the problems of high manpower consumption, affecting the rate of stitching, fabric yield, and coil misalignment, so as to save time and labor, avoid coil misalignment, and reduce the rate of defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

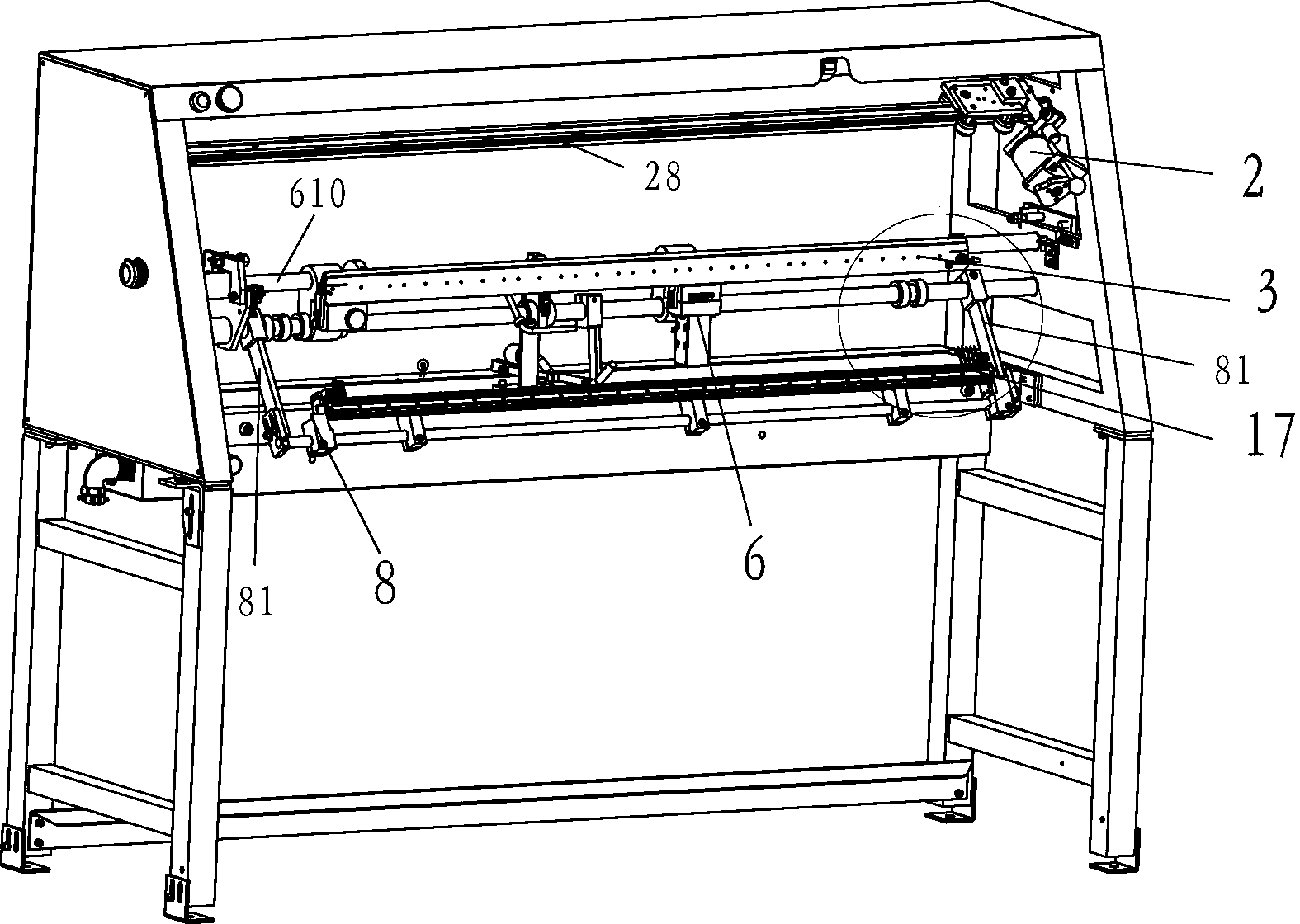

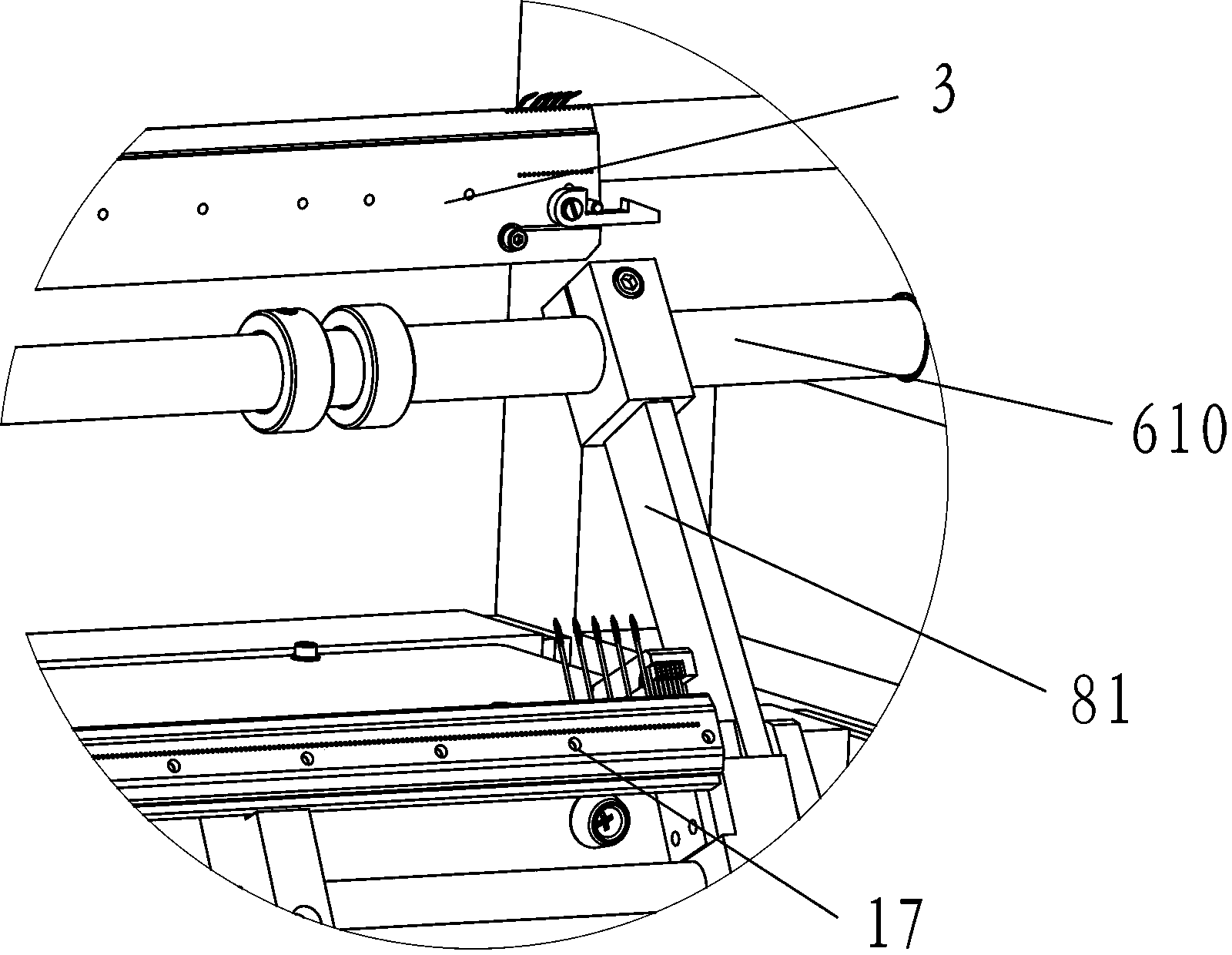

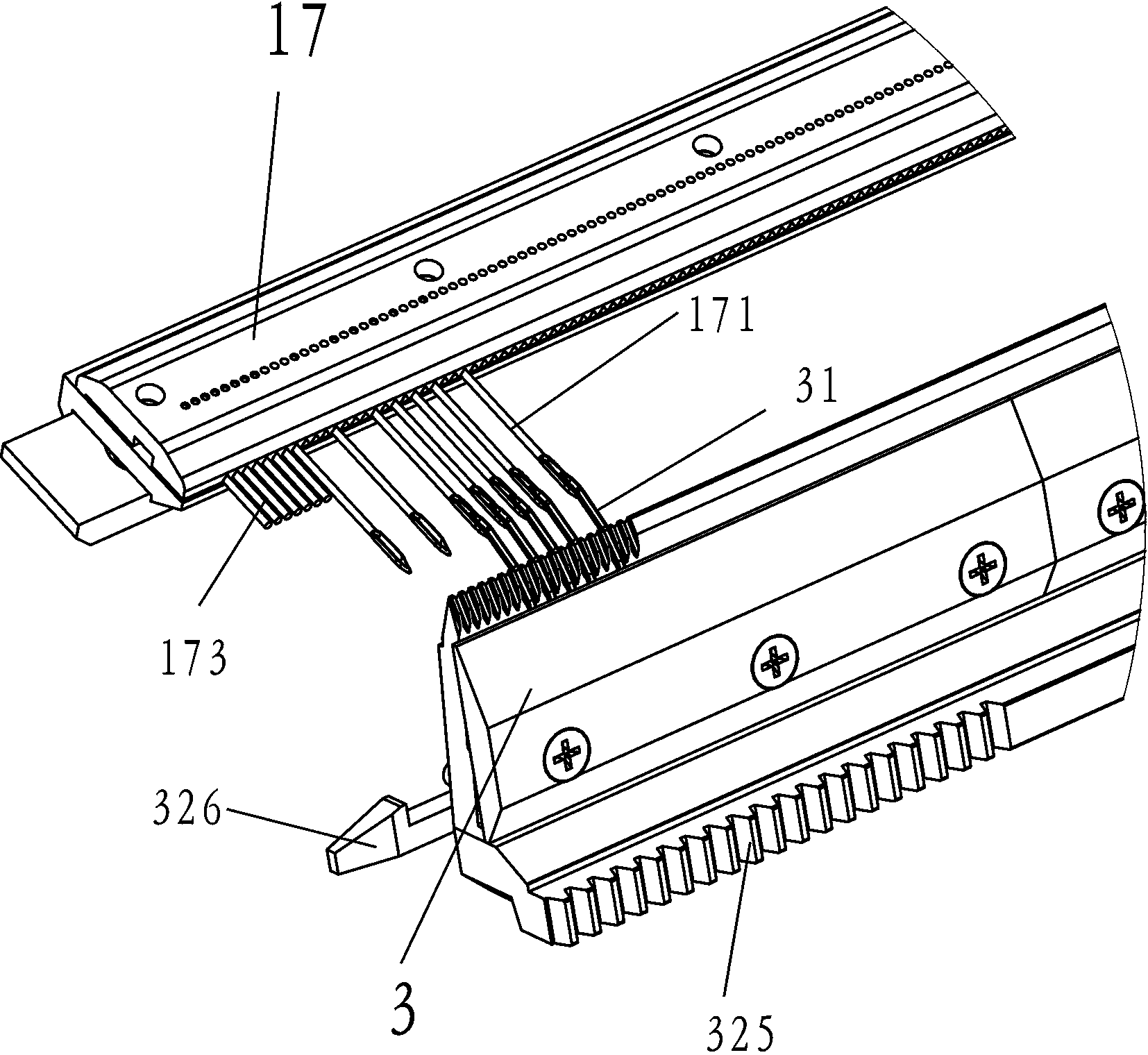

[0023] See attached picture. This embodiment includes a suture needle rake 3, a suture needle rake fixing seat 6, a cloth pressing device 2, a collar moving needle rake 17, a collar moving needle rake fixing seat 8, a sliding track 28 and a transmission shaft 610; the suture needle rake fixing seat 6 has a shaft sleeve connecting block 64, and the shaft sleeve connecting block 64 is fixed on the transmission shaft 610; the suture needle rake 3 is installed on the suture needle rake fixing seat 6, and the collar moving needle rake 17 is installed on the collar moving needle rake fixing seat 8; the collar moving needle rake fixing seat 8 has a rotating block 81, and the rotating block 81 is sleeved on the transmission shaft 610; the cloth pressing device 2 is installed on the sliding track 28.

[0024] The cloth pressing device 2 of this embodiment includes a cloth pressing motor 21, a cloth pressing block 22, a cloth pressing block fixing seat 222, a cloth pressing eccentric sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com