Cam control clutch power transmission distributor

A technology of transmission distributor and cam control, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc. It can solve the problems of inability to realize three-axis power transmission control, large structure occupation space, complex control, etc., and achieve compact structure , large carrying capacity and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

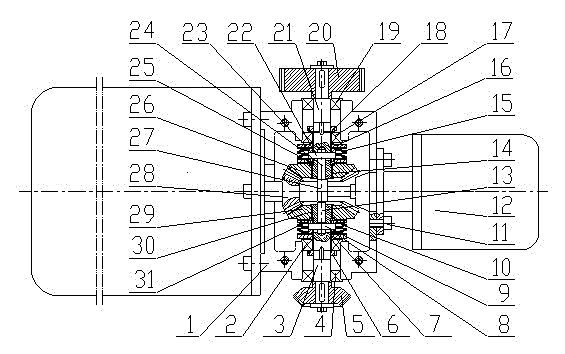

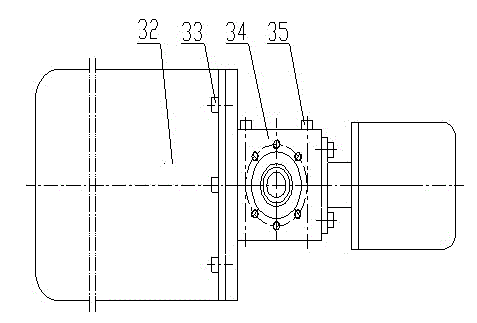

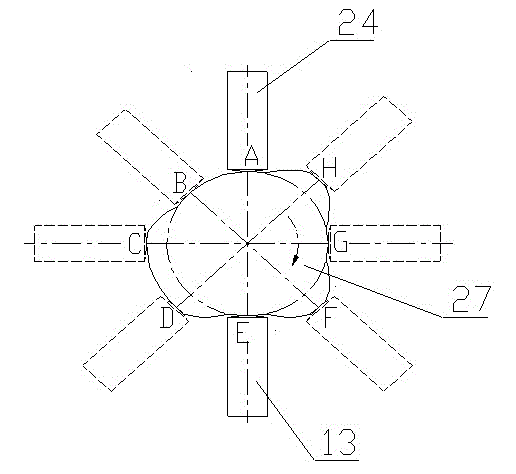

[0019] Lower casing 1 and upper casing 34 are fixed together to form casing with bolt 35, and the flange connection of main motor 32 on the left side of the casing is fixed with screw 33, and the flange connection of control motor 12 on the right side of the casing is fixed with screw 11. In the case, the driving gear 28 is fixed on the shaft end of the main motor 32 through a spline connection, and meshes with the front driven gear 29 and the rear driven gear 26 on both sides at the same time; The shaft end, the rear driven gear 26 is vacantly sleeved on the shaft end of the output shaft 21, and the two can rotate freely on the output shaft; The driven gear and the rear driven gear are positioned axially. Front bearing shell 30 and rear bearing shell 14 are respectively fixedly installed in the endoporus of front driven gear 29 and rear driven g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com