Chain lathedog and concrete pumping system

A clamp and chain technology, which is applied to variable capacity pump components, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of loose clamp connection, time-consuming and laborious disassembly process, and piston falling off, etc. , to achieve the effect of durable and reliable clamping connection, convenient disassembly and installation, and reliable fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

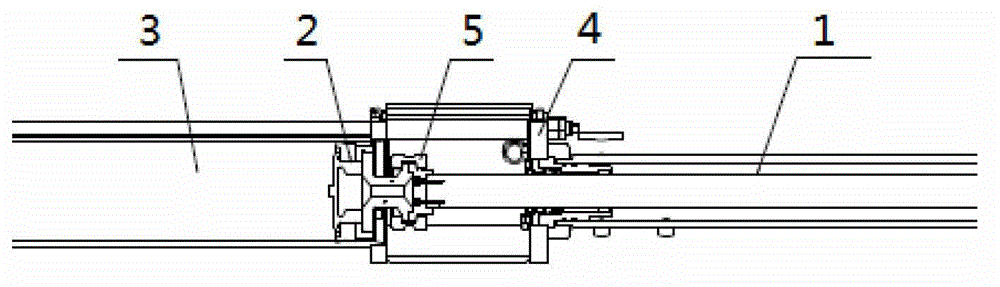

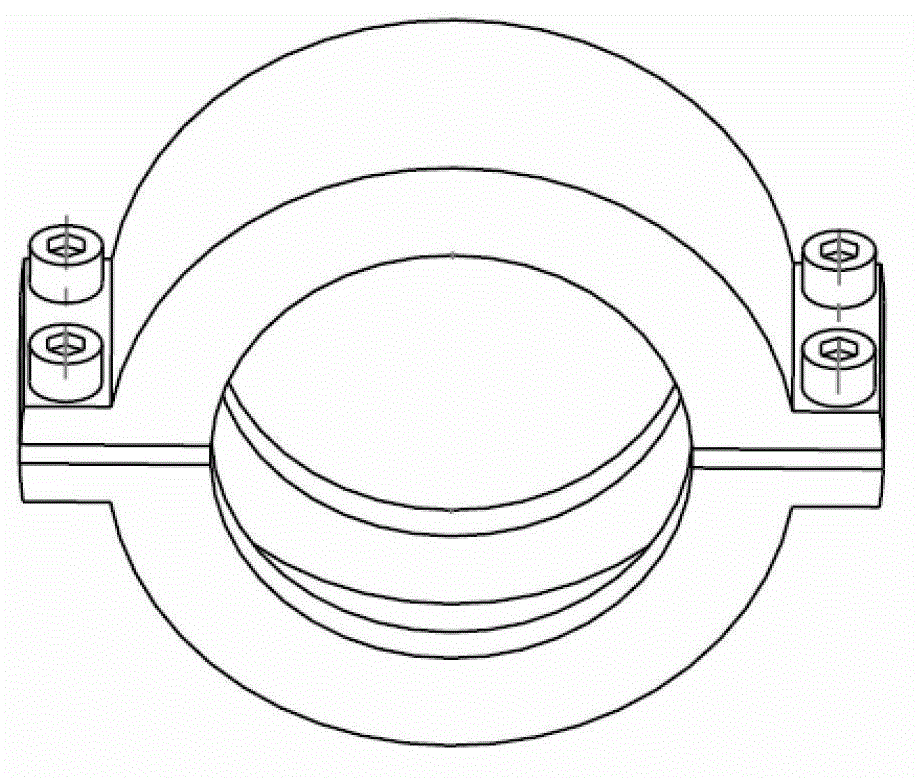

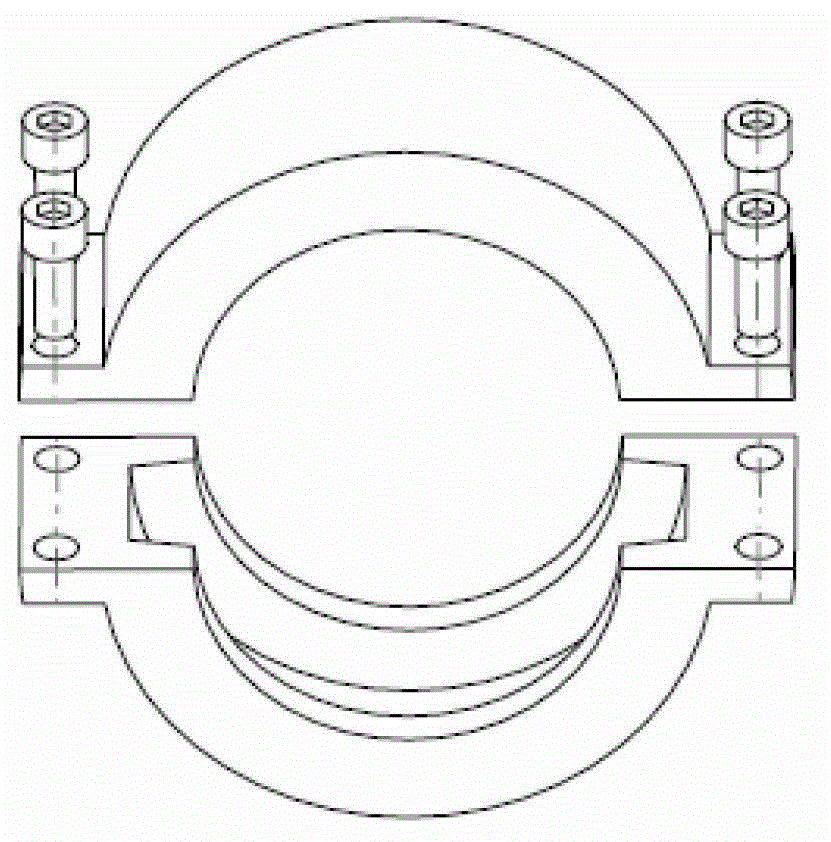

[0032] like Figure 5 As shown, it is a structural schematic diagram of an embodiment of the chain clamp of the present invention in an unfolded state. from Figure 5 It can be seen from the figure that the chain clamp in this embodiment includes a first clamp 1, a second clamp 2 and a connecting rod 3, wherein the first end of the first clamp 1 and the first end of the second clamp 2 The ends can be fixedly connected by bolts and nuts (see Image 6 ), the second end of the first clamp 1 and the second end of the second clamp 2 are respectively hinged with the two ends of the connecting rod 3, and the first clamp 1 and the second clamp 2 can rotate relative to the connecting rod 3 into the closed or expanded state.

[0033] from Image 6 It can be seen that one end of the first clamp 1 and the second clamp 2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com