Generator set capable of turning force down potential energy to electric energy and to consummated energy and remained energy

A technology of generating sets and generators, applied in the direction of mechanisms, machines/engines, mechanical equipment, etc. that generate mechanical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

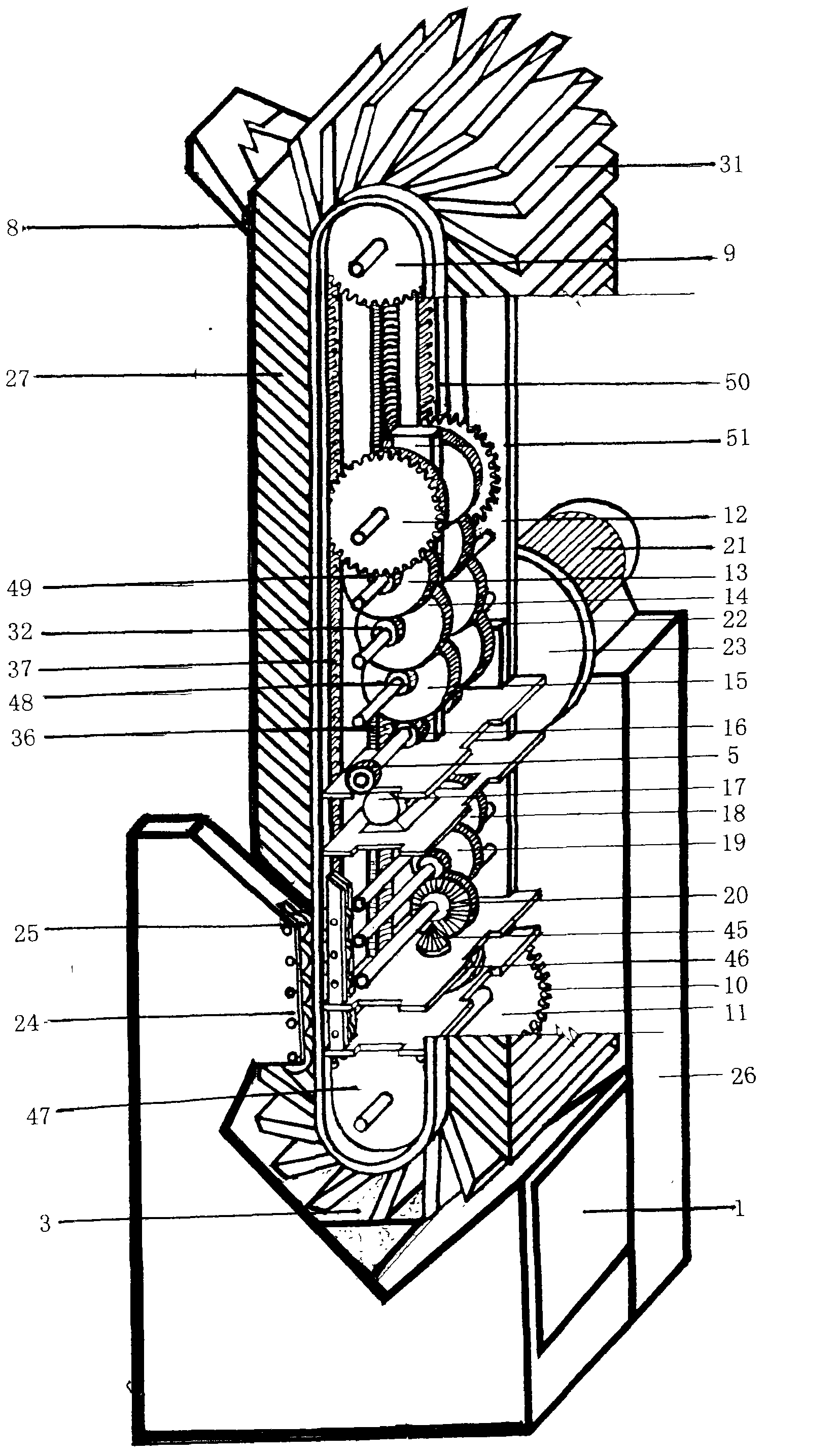

[0070] 1) Technical data of main components in the system

[0071] Digital control system; microcomputer controller (1) power: 1.7kw / h; pressure sensor power: 0.396kw / h; speed sensor (22) power: 0.4kw / h.

[0072] Starter motor system; motor power: 110kw / h, speed: 750r / min; shaft wheel diameter: 19.62cm; start wheel (5) diameter: 19.62cm; speed ratio between the shaft wheel and the start wheel (5): 1.

[0073] Power source guarantee system. Liquid (3), density: 1g / cm 3 . Lift of upper liquid pipe: 17.4m; infusion flow rate of liquid outlet (8) of upper liquid pipe: 136.51m 3 / h, 2275.1666dm 3 / min, 37.9195dm 3 / s, 1137.585dm 3 / 30s; liquid gravity flow: 136.51t / h, 2275.1666kg / min, 37.9195kg / s, 1137.585kg / 30s.

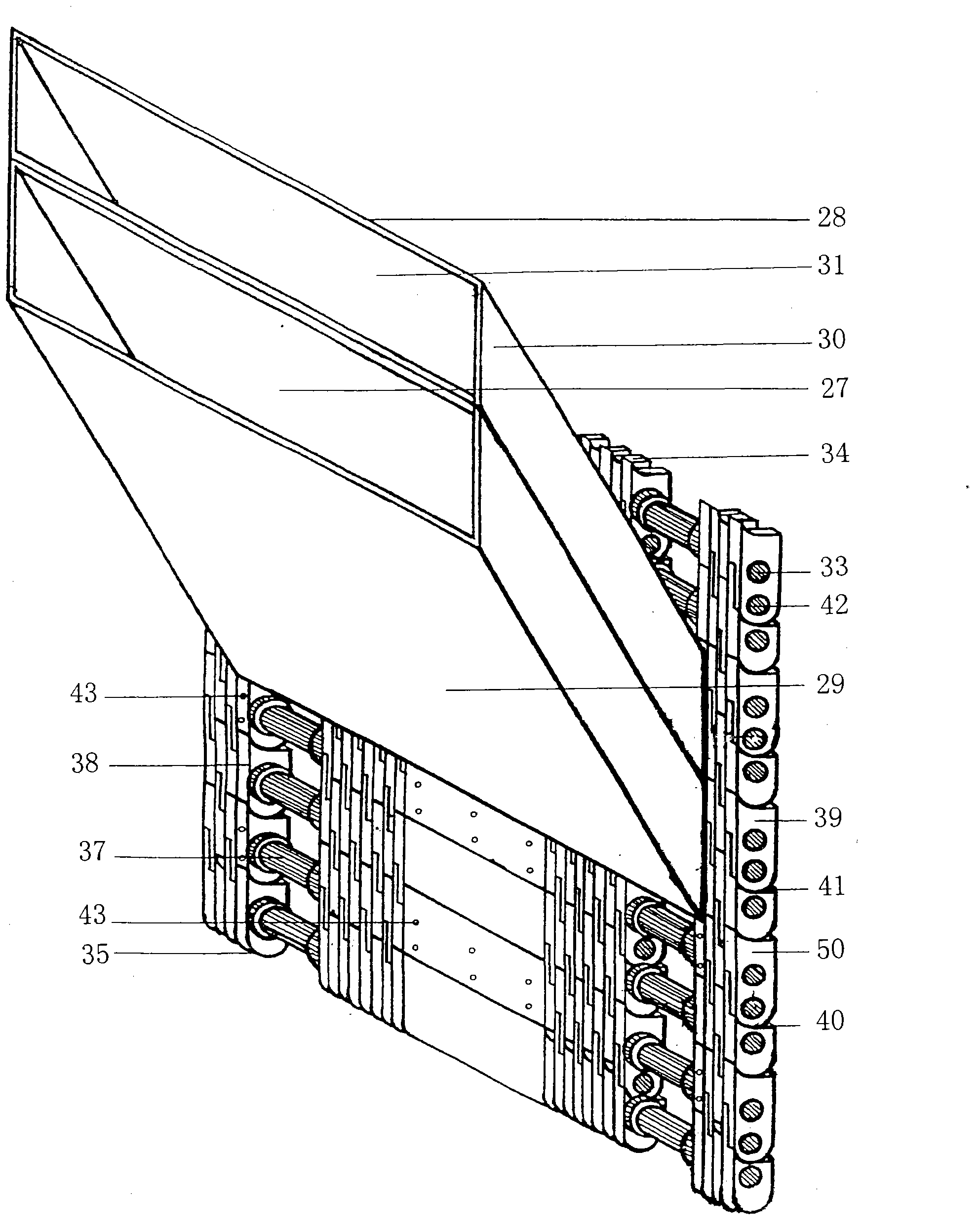

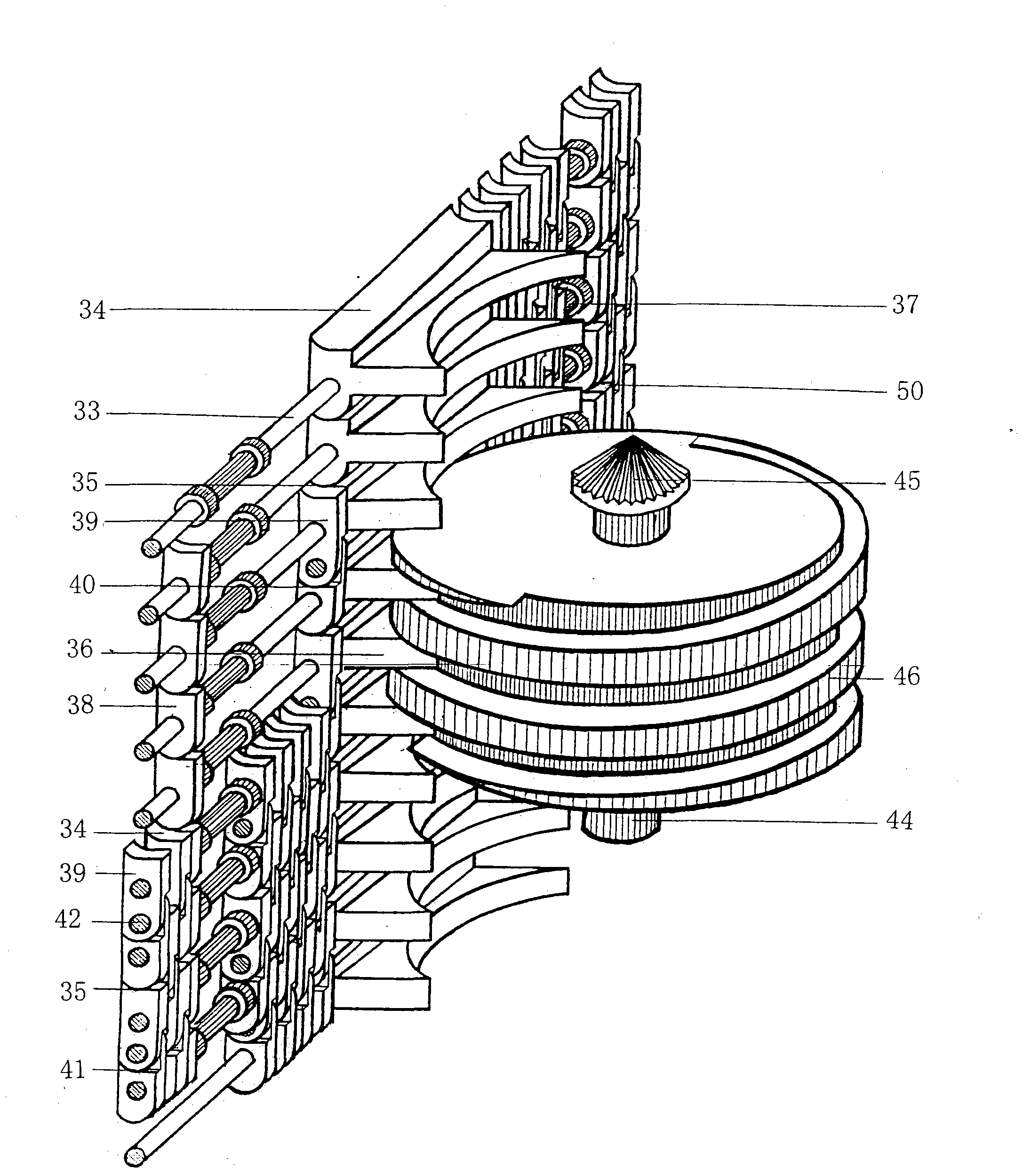

[0074] Gravity gathering system; load-bearing box (27), box opening (31) width: 30cm; load-bearing box (27) and box mouth (31) external length: 990cm; left box wall (30) thickness: 1cm; right box wall (30) Thickness: 1cm; inner length of the box: 988cm; outer wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com