Chemical integrated wastewater treatment process

A technology of sewage treatment and biochemical treatment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problem of environmental protection that cannot meet the treatment requirements of industrial park sewage treatment plants. Requirements and other issues, to achieve the effect of chromaticity reduction, good biochemical properties, and COD reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

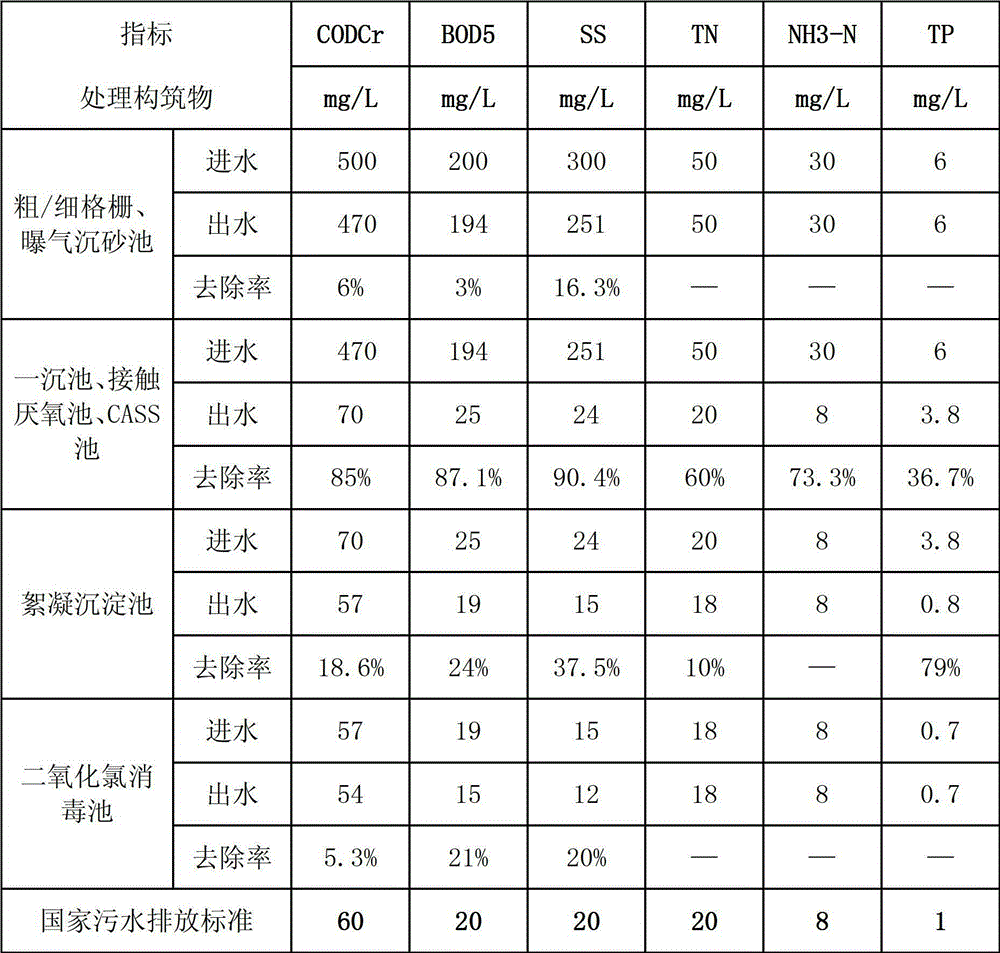

[0018] A comprehensive chemical wastewater treatment process, including the following steps:

[0019] (1) Physical and chemical treatment: Sewage enters the coarse grid sequentially from the water inlet, and first removes large floating objects in the sewage to prevent the subsequent water pump unit from being blocked. The sewage is lifted into the regulating tank through the lift pump to adjust the water quality and volume, so that the sewage will not affect the subsequent biochemical treatment due to excessive changes in the water quality and volume. After adjustment, it enters the Fenton physicochemical pond for Fenton oxidation treatment to remove the color and improve the biodegradability of the sewage. Finally, pass the primary sedimentation tank to complete the physical and chemical treatment of sewage;

[0020] (2) Biochemical treatment: The sewage that has completed the physical and chemical treatment in step (1) is lifted into the fine grid, aeration grit tank, and a sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com