Heat exchanger structure capable of prolonging service life of calcined coke heat exchanger

A technology of heat exchanger and calcined coke, which is applied in the field of heat exchanger structure and petroleum coke tank type calcination furnace, can solve the problems of large thermal expansion deformation, weld cracking, high material temperature, etc., to reduce thermal expansion deformation, reduce The effect of small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

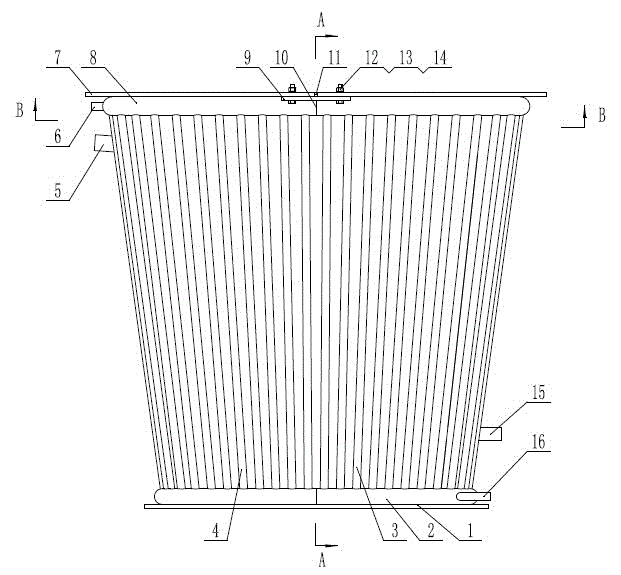

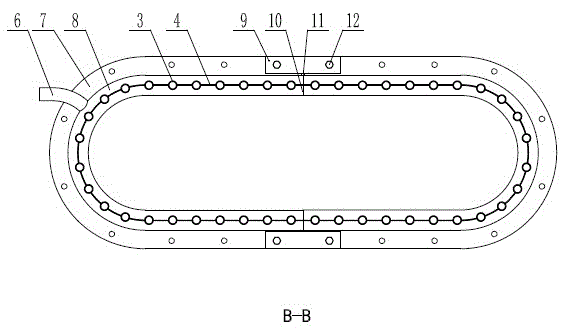

[0020] Figure 1~4 It is the best embodiment of the heat exchanger structure that improves the service life of the calcined coke heat exchanger. The following is combined with the attached Figure 1~4 The heat exchanger structure for increasing the service life of the calcined coke heat exchanger will be further described.

[0021] Refer to attached figure 1 : A heat exchanger structure for improving the service life of calcined coke heat exchangers, including an outer heat exchanger for surrounding a high-temperature material passage and an inner heat exchanger located at the center of the material passage. The outer heat exchanger includes an annular upper The header 8 and an annular lower header 2, the upper annular header 8 and the lower annular header 2 are all annular pipes, the upper annular header 8 is provided with a water outlet 6, and the lower annular header 2 is provided with a water inlet 16. A plurality of external heat exchange tubes 3 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com