Pig house cooling system

A pig house and water pipe technology, applied in the field of livestock breeding, can solve the problems of large equipment investment, high operating cost, inability to adapt to fermentation bed breeding and ventilation environment, etc., and achieve the effects of low construction cost and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

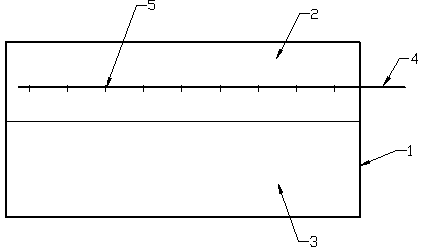

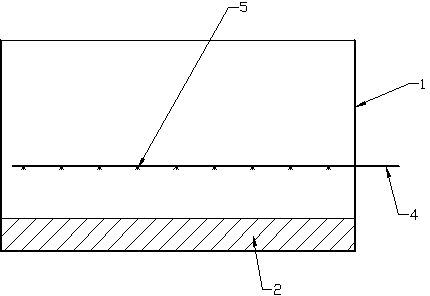

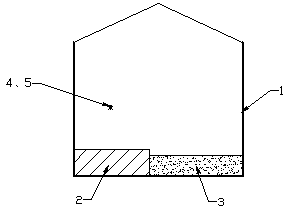

[0010] As shown in the figure, the pig house cooling system includes a pig house 1 with four walls and a roof. The ground of the pig house is divided into two parts laterally, that is, the cement bed 2 at the front and the fermentation bed 3 at the rear. The top of the cement bed is provided with a water pipe 4 longitudinally penetrating the pig house, the water pipe is connected with the water supply system, and spray nozzles 5 are arranged at intervals along the longitudinal direction on the water pipe. The height of the water pipe 4 from the cement bed is 1.2m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com