Electronic component cooling unit and power converting device

一种电力变换装置、电子部件的技术,应用在电气设备构造零部件、输出功率的转换装置、电气元件等方向,能够解决高额成本及制作时间、无法容易地变更制冷剂供给口及排出口的配置等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

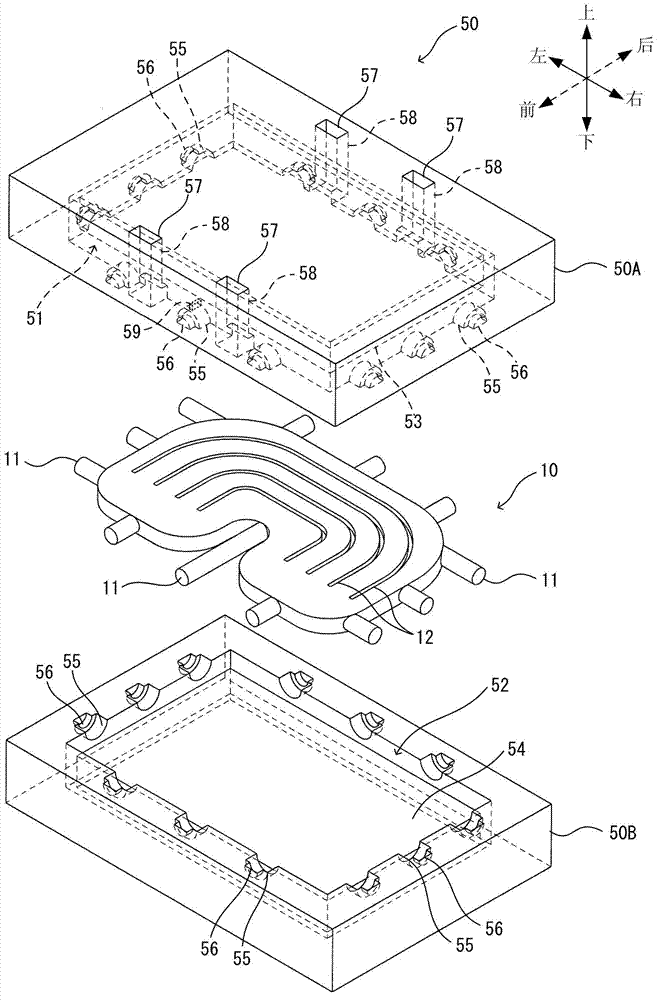

[0021] Hereinafter, embodiments will be described with reference to the drawings. In addition, in this embodiment, the case where the electronic component cooling module is applied to the power conversion apparatus which converts from alternating current to direct current or from direct current to alternating current is demonstrated as an example.

[0022]

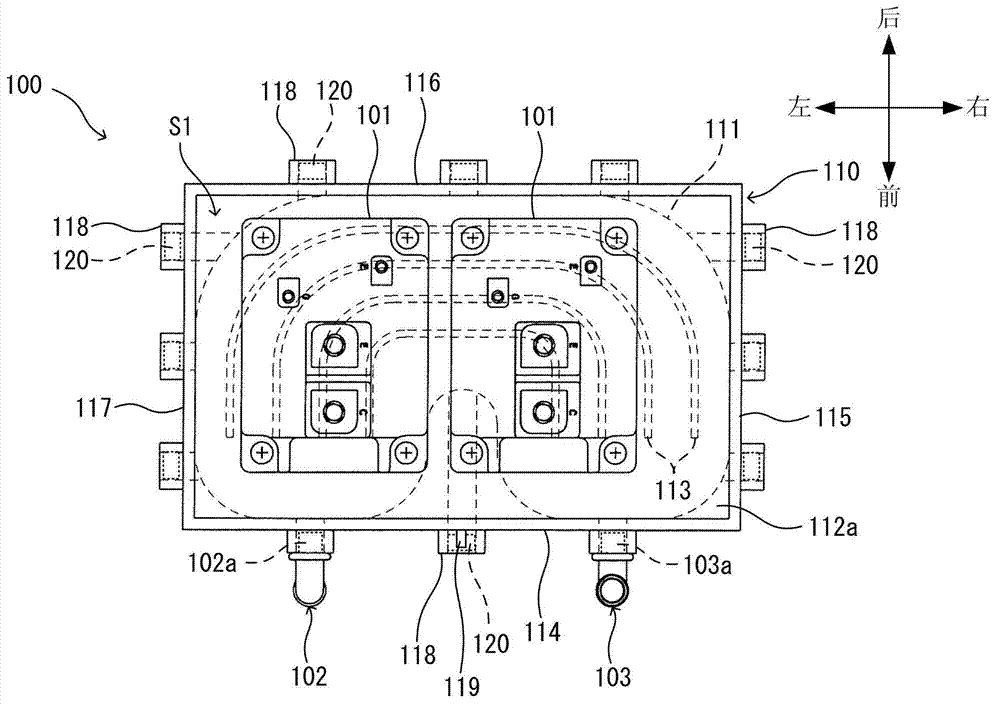

[0023] use figure 1 and figure 2 The overall configuration of the first power conversion device 100 will be described. In addition, for the convenience of description, the direction is set as follows. That is, will figure 1 Middle left direction ( figure 2 middle and bottom direction) to "Front", set the figure 1 middle upper right direction ( figure 2 center and upper direction) to "Back", set the figure 1 Middle left direction ( figure 2 center-left direction) to "Left", set the figure 1 Bottom right direction ( figure 2 center-right direction) to "Right", set the figure 1 upper middle direction ( fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com