Motor automatic control device

An automatic control device and electric contact technology, which is applied in the direction of emergency protection circuit device, deceleration device parts, electrical components, etc., can solve the problems of electric contact contact damage, long energized contact time, shortened motor life, etc., to achieve extended use Life, long working life, effect of reducing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

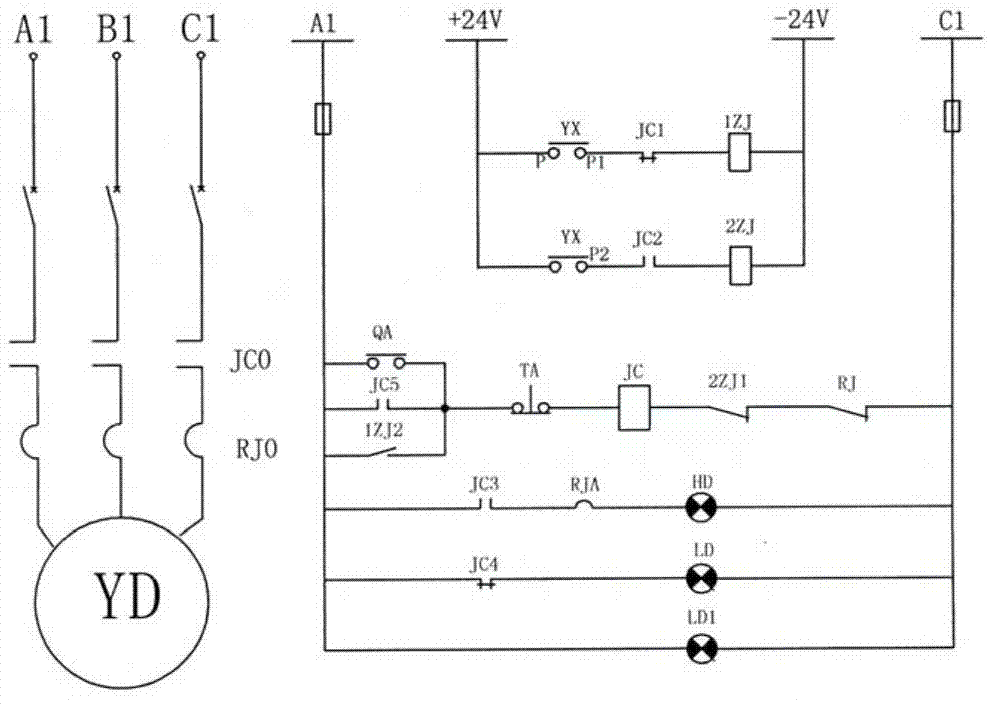

[0019] figure 1 It shows that the automatic motor control device, including the motor YD, the main contact of the contactor JC and the main contact of the thermal relay RJA are all connected in the power supply circuit of the motor YD (powered by three phase lines A1, B1 and C1), The electric contact barometer YX, the contact P of the electric contact barometer YX is connected to the positive pole of DC 24V, the contact P1 of the electric contact barometer YX is sequentially connected in series with the first normally closed contact JC1 of the contactor JC and the first intermediate relay 1ZJ is then connected to the DC 24V negative pole; the contact P2 of the electric contact barometer YX is connected in series with the first normally open contact JC2 of the contactor JC and the second intermediate relay 2ZJ is connected to the DC 24V negative pole; the first intermediate relay After the normally open contact 1ZJ2 is connected in series with the button TA, the contactor JC, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com