A high-voltage coaxial cable connector and its manufacturing method

A technology of coaxial cable and production method, which is applied in the direction of conductive connection, connection, line/collector parts, etc., can solve the problems of installation, disassembly, maintenance trouble, inconvenient operation, etc., and achieve the elimination of tip discharge and avoid corona discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

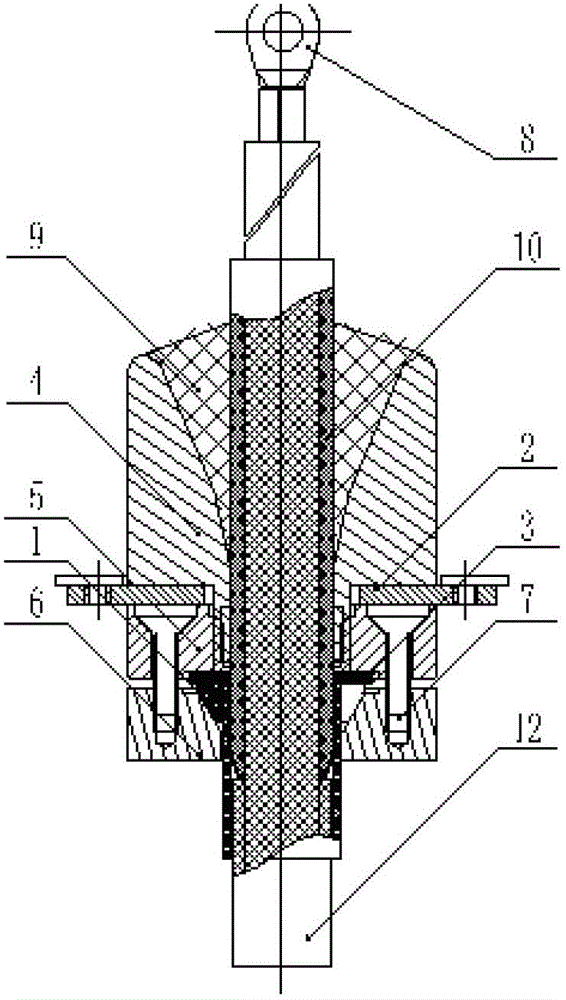

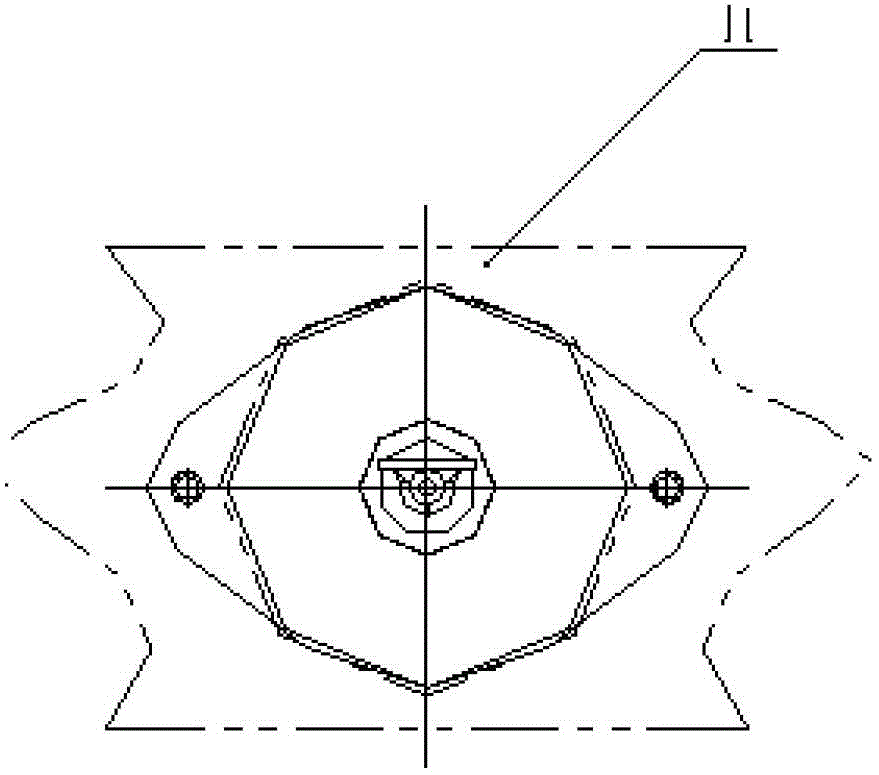

[0023] Such as Figure 1-3 As shown, a high-voltage coaxial cable connector, the connector is composed of a coaxial ring assembly in which the shielding body 4 is connected to the outer conductor of the coaxial cable 12, and the shielding body 4 is threaded with the coaxial ring The components are connected, and a buffer component is provided between the shielding body and the coaxial cable.

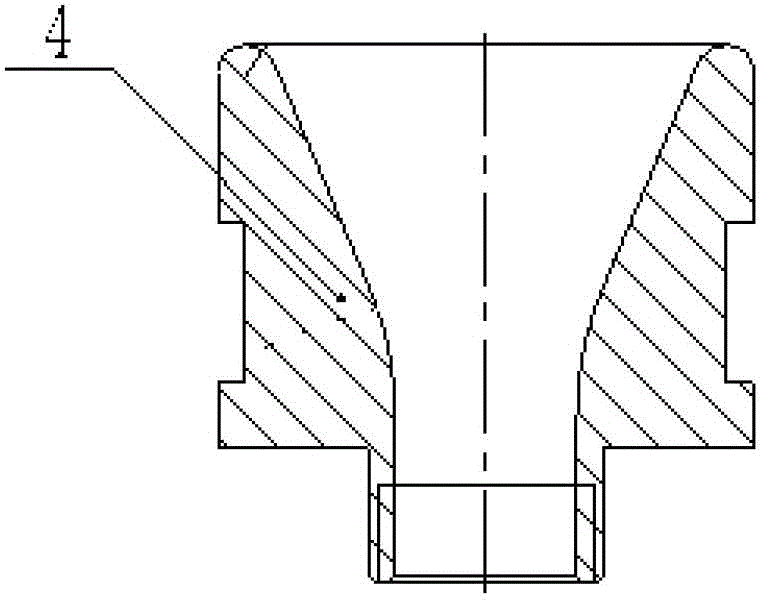

[0024] The shield 4 is in the shape of a "bucket", and the inner surface of the shield 4 is provided with a tapered area, which forms a tapered surface radially outward along the direction from the inlet end of the shield 4 towards the far end of the shield 4. There is a smooth arc transition between the upper port and the tapered surface of the shielding body 4, the tapered surface of the shielding body and the lower port, and the lower port of the shielding body 4 is provided with an external thread connected with the coaxial ring assembly . The size and depth of the outer opening of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com